Ho hloekisa ka laser ke mokhoa o atlehang oa ho tlosa bokaholimo bo tiileng ba lisebelisoa tse fapaneng le boholo ba likaroloana tse litšila le lera la filimi.Ka khanya e phahameng le tataiso e ntle e tsoelang pele kapa ea pulsed laser, ka ho tsepamisa mohopolo le ho bōptjoa ha matheba ho theha sebopeho se itseng sa letheba le kabo ea matla ea lebone la laser, le khantšoa ka holim'a thepa e silafetseng e lokelang ho hloekisoa, lisebelisoa tse silafetseng tse khomaretsoeng li monya laser. matla, e tla hlahisa letoto la lits'ebetso tse rarahaneng tsa 'mele le tsa lik'hemik'hale tse kang ho sisinyeha, ho qhibiliha, ho chesa, esita le gasification,' me qetellong e etse litšila tse tsoang holim'a lintho tse bonahalang Esita le haeba ketso ea laser holim'a metsi a hloekisitsoeng, boholo ba bona bo bontšoa. tima, substrate e ke ke ea baka tšenyo, e le ho finyella phello ea ho hloekisa.Setšoantšo se latelang: ho tlosa mafome holim'a khoele le ho hloekisa.

Ho hloekisa ka laser ho ka aroloa ho latela maemo a fapaneng a lihlopha.Joalo ka ho latela ts'ebetso ea laser ea ho hloekisa holim'a substrate e koahetsoeng ka filimi ea mokelikeli e arotsoe ka ho hloekisa laser le ho hloekisa laser e metsi.Ea pele ke mahlaseli a tobileng a silafatso ea laser holim'a metsi, e qetellang e lokela ho sebelisoa ho mongobo o hloekisang oa laser kapa filimi ea metsi.Ho hloekisoa ha laser ka mokhoa o phahameng, empa ho hloekisa ka laser ho hloka hore ho behoe filimi ea metsi, e hlokang hore sebopeho sa filimi ea metsi se ke ke sa fetola sebopeho sa thepa ea substrate ka boeona.Ka hona, mabapi le theknoloji ea ho hloekisa ka laser e omileng, ho hloekisa ka laser ho na le meeli e itseng molemong oa ts'ebeliso.Ho hloekisa ka laser e omileng hona joale ke mokhoa o sebelisoang ka ho fetisisa oa ho hloekisa ka laser, o sebelisang lebone la laser ho khantša bokaholimo ba mosebetsi ka kotloloho ho tlosa likaroloana le lifilimi tse tšesaane.

LaserDry Ctshetlehile

Molao-motheo oa ho hloekisa ka laser ke karoloana le substrate ea thepa ka laser irradiation, phetoho ea hang-hang ea matla a khanyang a monyang mocheso, a bakang karoloana kapa substrate kapa katoloso ea hang-hang ea mocheso, pakeng tsa karoloana le substrate hang-hang e ile ea hlahisa lebelo, matla a hlahisoang ke ho potlakisa ho hlōla adsorption pakeng tsa karoloana le substrate, e le hore karoloana e tsoang holim'a substrate.

Ho latela mekhoa e fapaneng ea ho monya ea ho hloekisa ka laser, ho hloekisa ka laser ho ka aroloa ka mefuta e 'meli e meholo e latelang:

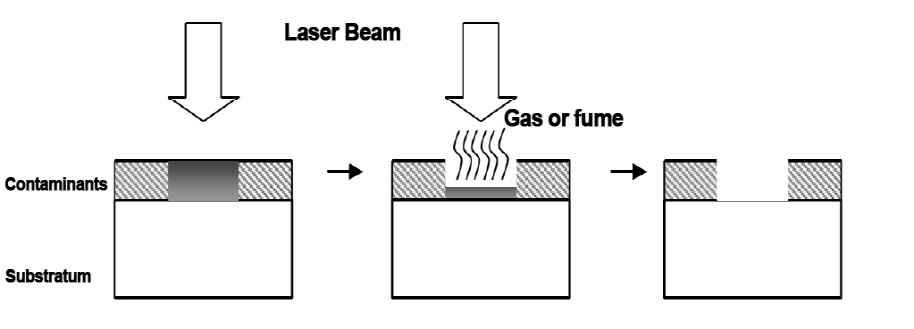

1.Fkapa ntlha e qhibilihang e kholo ho feta lintho tsa motsoali (kapa liphapang tsa sekhahla sa ho monya ka laser) tsa likaroloana tsa lerole: likaroloana tse monyang mahlaseli a laser a matla ho feta ho monya ha substrate (a) kapa ka tsela e fapaneng (b), ebe likaroloana li monya leseli la laser. matla a fetoletsoeng ho matla a mocheso, a bakang katoloso ea mocheso oa likaroloana, le hoja palo ea katoloso ea mocheso e nyenyane haholo, empa katoloso ea mocheso e ka nako e khutšoanyane haholo, kahoo ho tla ba le ho potlakisa ho hoholo hang-hang holim'a substrate, substrate counter-action holim'a likaroloana, matla a ho hlōla matla a ho kopanya adsorption, e le hore likaroloana tse tsoang ho substrate, molao-motheo oa setšoantšo sa schematic joalokaha ho bontšitsoe setšoantšong sa 1..

2. Bakeng sa ntlha e ka tlaase ea ho bela ea litšila: mobu oa holim'a mobu o monya ka ho toba matla a laser, hang-hang mocheso o phahameng o belang mouoane, mouoane o tobileng ho tlosa litšila, molao-motheo o bontšitsoeng ho Setšoantšo sa 2.

LaserWet CtshetlehilePrinciple

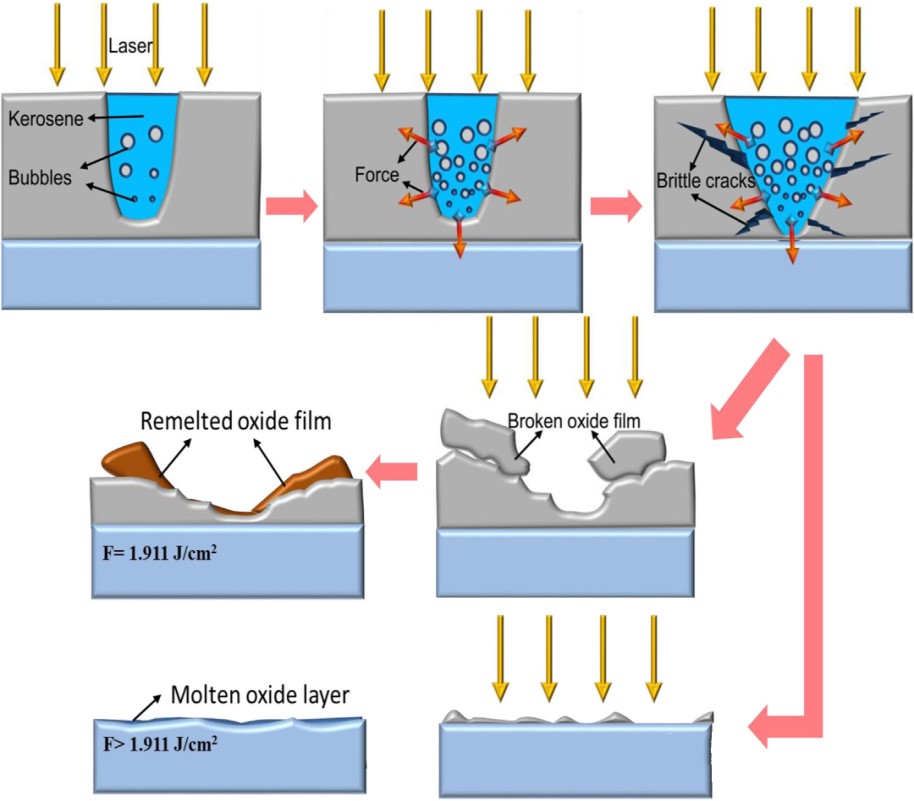

Ho hloekisa ka laser ho boetse ho tsejoa e le ho hloekisa mouoane oa laser, ho fapana le ho omisa, ho hloekisa metsi ho ka pel'a karolo e nyenyane ea filimi ea metsi e teteaneng ea microns kapa filimi ea mecha ea litaba holim'a likarolo tsa ho hloekisa, filimi ea metsi ka laser irradiation. mocheso filimi ea metsi e nyoloha hang-hang 'me e hlahisa palo e kholo ea li-bubble ho karabelo ea gasification, ho phatloha ha gasification ho hlahisoang ke tšusumetso ea likaroloana le substrate ho hlōla matla a adsorption pakeng tsa.Ho ea ka likaroloana, filimi ea metsi le substrate ho laser wavelength absorption coefficient e fapane, laser wet cleaner e ka aroloa ka mefuta e meraro.

1.Ho monya ho matla ha matla a laser ka substrate

Laser irradiation holim'a substrate le filimi ea metsi, ho monya ha laser ka substrate ho kholo haholo ho feta filimi ea mokelikeli, kahoo mouoane o phatlohang o hlaha sebopeho pakeng tsa substrate le filimi ea metsi, joalokaha ho bontšitsoe setšoantšong se ka tlase.Ka khopolo, ha nako e ntse e fokotseha, ho ba bonolo haholoanyane ho hlahisa mocheso o moholo mateanong a matekoane, e leng se fellang ka ho phatloha ho hoholo.

2. Ho monya ka matla ha matla a laser ka lera la mokelikeli

Molao-motheo oa ho hloekisa hona ke hore filimi ea mokelikeli e nka boholo ba matla a laser, 'me ho phatloha ho phatloha ho etsahala holim'a filimi ea metsi, joalokaha ho bontšitsoe setšoantšong se ka tlase.Ka nako ena, katleho ea ho hloekisa laser ha e ntle joaloka ha ho kenngoa ha substrate, hobane ka nako ena ts'ebetso ea ho phatloha holim'a filimi ea metsi.Le hoja ho kenngoa ha substrate, li-bubble le ho phatloha ho etsahala mateanong a karolo ea substrate le filimi ea metsi, phello e phatlohang e bonolo ho sutumelletsa likaroloana hole le bokaholimo ba substrate, ka hona, phello ea ho hloekisa ea substrate e molemo.

3.Ka bobeli substrate le lera la metsi li monya matla a laser

Ka nako ena, ts'ebetso ea ho hloekisa e tlaase haholo, ka mor'a hore mahlaseli a laser a kenelle filiming ea metsi, karolo ea matla a laser e kenngoa, matla a qhalakantsoeng ho pholletsa le filimi ea metsi ka hare, filimi ea metsi e belang ho hlahisa li-bubble, matla a setseng a laser. ka filimi ea metsi e kenngoa ke substrate, joalokaha ho bontšitsoe setšoantšong.Mokhoa ona o hloka matla a mangata a laser ho hlahisa lipompong tse belang pele ho phatloha ho etsahala.Ka hona katleho ea mokhoa ona e tlase haholo.

Ho hloekisa ka laser ho sebelisa substrate absorption, kaha matla a mangata a laser a kenngoa ke substrate, a tla etsa filimi ea metsi le substrate junction overheating, li-bubble ho interface, ha li bapisoa le ho hloekisa ka mokhoa o omileng, metsi ke tšebeliso ea ho phatloha ha bubble ea junction. ka phello ea ho hloekisa ka laser, ha u ntse u ka khetha ho eketsa palo e itseng ea lik'hemik'hale filiming ea mokelikeli le likaroloana tse silafatsang ho karabelo ea lik'hemik'hale ho fokotsa likaroloana le substrate Matla a adsorption pakeng tsa thepa, e le ho fokotsa monyako oa laser. ho hloekisa.Ka hona, ho hloekisa ka metsi ho ka ntlafatsa katleho ea ho hloekisa ho isa tekanyong e itseng, empa ka nako e ts'oanang ho na le mathata a itseng, ho kenngoa ha filimi ea metsi ho ka lebisa tšilafalo e ncha, 'me botenya ba filimi ea metsi bo thata ho laola.

LintlhaAe amangQboleng baLaserCtshetlehile

Phello eaLaserWavelength

Sepheo sa ho hloekisa ka laser ke ho monya ka laser, ka hona, khethong ea mohloli oa laser, ntho ea pele eo u lokelang ho e etsa ke ho kopanya litšobotsi tsa ho monya ha leseli la sesebelisoa sa ho hloekisa, khetha laser e loketseng ea wavelength e le mohloli oa leseli la laser.Ho phaella moo, bo-rasaense ba tsoang linaheng tse ling lipatlisiso tsa liteko li bontša hore ho hloekisa litšobotsi tse tšoanang tsa likaroloana tse silafatsang, ho khutsufatsa bolelele ba maqhubu, matla a ho hloekisa a laser, ho theola monyako oa ho hloekisa.Ho ka bonoa hore, molemong oa ho kopana le litšoaneleho tsa ho monya leseli la thepa, molemong oa ho ntlafatsa ts'ebetso le ts'ebetso ea ho hloekisa, o lokela ho khetha bolelele bo khuts'oane ba laser e le mohloli oa leseli oa ho hloekisa.

Phello eaPetsoeDensity

Ho hloekisoa ka laser, matla a matla a laser ho na le moeli o ka holimo oa tšenyo le moeli o tlase oa ho hloekisa.Lethathamong lena, matla a laser a matla a ho hloekisa ka laser, matla a ho hloekisa a hola, le phello e hlakileng ea ho hloekisa.Ka hona, ha ea lokela ho senya thepa ea substrate tabeng, e lokela ho ba holimo ka hohle kamoo ho ka khonehang ho eketsa matla a matla a laser.

Phello eaPulseWidth

The laser mohloli oa tlhoekiso ea laser e ka ba leseli le tsoelang pele kapa leseli la pulsed, laser ea pulsed e ka fana ka matla a holimo haholo, kahoo e ka fihlela litlhoko tsa monyako habonolo.'Me ho ile ha fumanoa hore ts'ebetsong ea ho hloekisa holim'a substrate e bakoang ke liphello tsa mocheso, pulsed laser impact e nyane, laser e tsoelang pele e bakoang ke tšusumetso ea mocheso ea sebaka seo e kholoanyane.

TheEphello eaScanningSpeed leNpalo eaTimes

Ho hlakile hore ts'ebetsong ea ho hloekisa ka laser, ha lebelo la sekeno sa laser le potlakisa makhetlo a fokolang, ho ba le ts'ebetso e phahameng ea ho hloekisa, empa sena se ka baka ho theoha ha phello ea tlhoekiso.Ka hona, ts'ebetsong ea kopo ea ho hloekisa, e lokela ho ipapisa le litšoaneleho tsa thepa ea ho hloekisa workpiece le boemo ba tšilafalo ho khetha lebelo le nepahetseng la ho hlahloba le palo ea lisebelisoa.Ho hlahloba sekhahla sa ho fetana joalo-joalo ho tla ama phello ea ho hloekisa.

Phello eaAthaba eaDefocusing

Ho hloekisa ka laser ka pel'a laser haholo ka motsoako o itseng oa lense e tsepamisitseng maikutlo bakeng sa ho kopana, le ts'ebetso ea 'nete ea ho hloekisa ka laser, hangata molemong oa ho theola maikutlo, palo e kholo ea defocusing, e khanyang holim'a thepa e kholoanyane, sebaka se seholo. sebaka sa ho sekena, ho ba le ts'ebetso e phahameng.'Me ka matla a feletseng a tiile, ho fokotseha ha palo ea defocusing, matla a maholo a matla a laser, matla a ho hloekisa a matla.

Kakaretso

Kaha tlhoekiso ea laser ha e sebelise metsoako ea lik'hemik'hale kapa lisebelisoa tse ling, e na le botsoalle ba tikoloho, e bolokehile ho sebetsa ebile e na le melemo e mengata haholo:

1. botala le tikoloho, ntle le tšebeliso ea lik'hemik'hale leha e le life le tharollo ea ho hloekisa,

2. ho hloekisa litšila haholo-holo phofo e tiileng, boholo bo nyane, ho bonolo ho bokelloa le ho bokelloa hape,

3. Ho hloekisa mosi oa litšila ho bonolo ho monya le ho o tšoara, lerata le tlaase, ha ho kotsi bophelong ba motho,

4. Ho hloekisa ho se kopane, ha ho na masala a mecha ea litaba, ha ho na tšilafalo ea bobeli,

5. Ho hloekisa ho khetha ho ka finyelloa, ha ho na tšenyo ho li-substrates,

6. Ha ho na tšebeliso e mahareng e sebetsang, e sebelisa motlakase feela, litšenyehelo tse tlase tsa tšebeliso le tlhokomelo,

7. Easy ho fihlela othomathike, fokotsa matla a mosebetsi,

8. E loketse libaka kapa libaka tseo ho leng thata ho fihla ho tsona, bakeng sa tikoloho e kotsi kapa e kotsi.

Maven Laser Automation Co., Ltd. ke moetsi ea hloahloa oa mochini oa welding oa laser, mochini o hloekisang oa laser, mochini o tšoaeang laser ka lilemo tse 14.Ho tloha ka 2008, Maven Laser e tsepamisitse maikutlo ho nts'etsopele le tlhahiso ea mefuta e fapaneng ea mochini oa laser engraving / welding / tšoaea / ho hloekisa o nang le tsamaiso e tsoetseng pele, matla a matla a lipatlisiso le leano le tsitsitseng la ho ikopanya ha lichaba tsa lefatše, Maven Laser e thehile tsamaiso e phethahetseng ea thekiso ea lihlahisoa le litšebeletso Chaena le lefatšeng ka bophara, etsa lets'oao la lefats'e indastering ea laser.

Ho feta moo, re ela hloko haholo ts'ebeletso ea kamora thekiso, Ts'ebeletso e ntle le boleng bo botle li bohlokoa joalo ka hore Maven Laser e tla latela moea "Credibility and Integrity", leka ka ho fetisisa ho fa bareki sehlahisoa se phahameng le tšebeletso e betere.

Maven Laser - morekisi ea tšepahalang oa lisebelisoa tsa Laser!

Rea u amohela ho sebelisana le rona le ho fumana win-win.

Nako ea poso: May-05-2023