Roboto ea indasteris li sebelisoa haholo tlhahisong ea indasteri, joalo ka tlhahiso ea likoloi, lisebelisoa tsa motlakase, lijo, joalo-joalo Li ka nka sebaka sa ts'ebetso ea mochini e pheta-phetoang 'me ke mechini e itšetlehileng ka matla a eona le bokhoni ba ho laola ho fihlela mesebetsi e fapaneng. E khona ho mamella taelo ea motho hape e ka sebetsa ho latela mananeo a reriloeng esale pele. Joale re bua ka likarolo tsa mantlha tsa mantlha tsaroboto ea indasteris.

1.Sehlooho

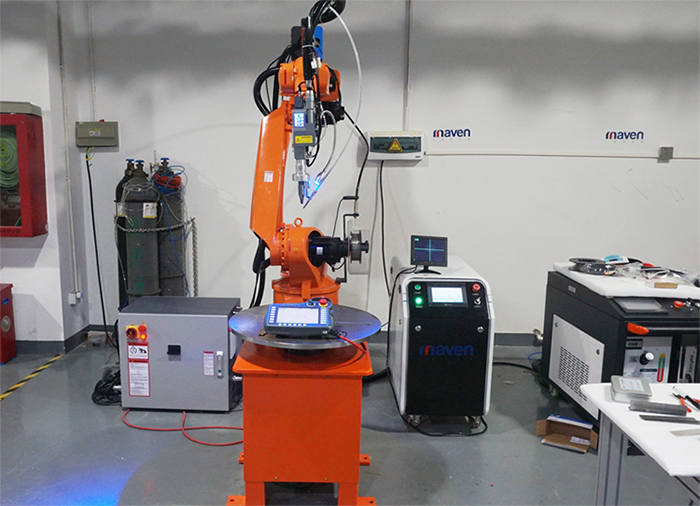

Mochini o ka sehloohong ke setsi sa mochini le mochini o ts'oarang, ho kenyeletsoa letsoho le leholo, forearm, letsoho le letsoho, tse etsang sistimi ea maemo a mangata a tokoloho. Liroboto tse ling le tsona li na le mekhoa ea ho tsamaea.Roboto ea indasterisna le likhato tse 6 tsa tokoloho kapa ho feta. Hangata letsoho le na le likhato tse 1 ho isa ho tse 3 tsa bolokolohi ba ho tsamaea.

2. Mokhoa oa ho khanna

Mokhoa oa ho khanna oaroboto ea indasterise arotsoe ka mekhahlelo e meraro ho latela mohloli oa matla: hydraulic, pneumatic le motlakase. Mefuta ena e meraro e ka boela ea kopanngoa hore e be tsamaiso ea composite drive ho latela litlhoko. Kapa e tsamaisoa ka mokhoa o sa tobang ka mekhoa ea phetisetso ea mochini joalo ka mabanta a lumellanang, literene tsa gear le likere. Sistimi ea ho khanna e na le sesebelisoa sa matla le mochini oa phetisetso, o sebelisetsoang ho kenya tšebetsong liketso tse lumellanang tsa mochini. E 'ngoe le e' ngoe ea mefuta ena e meraro ea litsamaiso tsa mantlha tsa drive e na le litšobotsi tsa eona. Mokhoa oa morao-rao ke oa tsamaiso ea motlakase. Ka lebaka la inertia e tlase, li-motor tse kholo tsa AC le DC servo le li-drive tsa tsona tse tšehetsang servo (li-converter tsa maqhubu a AC, li-modulator tsa DC pulse wide) li sebelisoa haholo. Mofuta ona oa sistimi ha o hloke phetolo ea matla, o bonolo ho o sebelisa, 'me o na le taolo e hlokolosi. Lienjiniere tse ngata li hloka mochine o bonolo oa phetisetso: se fokotsang matla. Meno a eona a sebelisa sesebelisoa sa lebelo la gear ho fokotsa palo ea lipotoloho tse ka morao tsa enjene ho palo e hlokahalang ea ho potoloha le ho fumana sesebelisoa se seholo sa torque, ka hona ho fokotsa lebelo le ho eketsa torque. Ha mojaro o le moholo, servo motor e eketseha ka bofofu Matla a theko e boima haholo, 'me torque e hlahisoang e ka eketsoa ka mochine o fokotsang ka har'a lebelo le loketseng la lebelo. Li-motor tsa servo li na le mocheso le ho sisinyeha ha maqhubu a tlase ha li sebetsa ka maqhubu a tlase. Mosebetsi oa nako e telele le o pheta-phetoang ha o thuse ho netefatsa ts'ebetso e nepahetseng le e ka tšeptjoang. Ho ba teng ha enjene ea phokotso e nepahetseng ho lumella servo motor ho sebetsa ka lebelo le nepahetseng, ho matlafatsa ho tiea ha 'mele oa mochini le ho hlahisa torque e kholoanyane. Ho na le li-conducers tse peli tse ka sehloohong kajeno: "haronic reducer" le RV reducer.

3.Mokhoa oa ho laola

Thetsamaiso ea lirobotoke boko ba roboto le ntlha e ka sehloohong e khethollang mesebetsi le mesebetsi ea roboto. Sistimi ea taolo e romella matšoao a litaelo ho sistimi ea ho khanna le mochini oa ts'ebetso ho latela lenaneo la ho kenya, 'me oa li laola. Mosebetsi o ka sehloohong oaroboto ea indasteri taolo thekenoloji ke ho laola mefuta e fapaneng ya mesebetsi, boemo le trajectory, le nako ea ketso earoboto ea indasteris sebakeng sa mosebetsi. E na le litšoaneleho tsa lenaneo le bonolo, ts'ebetso ea menyetla ea software, sehokelo sa tšebelisano se bonolo sa khomphutha ea motho, likhothaletso tsa ts'ebetso ea inthanete le ts'ebeliso e bonolo. Sistimi ea taolo ke motheo oa roboto, 'me lik'hamphani tse amehang tsa kantle ho naha li koaletsoe haholo litekong tsa rona. Lilemong tsa morao tjena, ka nts'etsopele ea thekenoloji ea microelectronics, ts'ebetso ea microprocessors e se e phahame le ho feta, 'me theko e fetohile e theko e tlaase ebile e theko e tlaase. Hona joale, li-microprocessors tsa 32-bit tse bitsang lidolara tse 1-2 tsa US li hlahile 'marakeng. Li-microprocessors tse theko e tlaase li tlisitse menyetla e mecha ea ntlafatso ho balaoli ba liroboto, e leng ho nolofalletsang ho hlahisa liroboto tse theko e tlaase, tse sebetsang hantle haholo. E le ho etsa hore tsamaiso e be le bokhoni bo lekaneng ba lik'homphieutha le polokelo, balaoli ba liroboto ba se ba entsoe ka lihlopha tse matla tsa ARM, letoto la DSP, letoto la POWERPC, letoto la Intel le lisebelisoa tse ling. Kaha mesebetsi le mesebetsi ea li-chips tse teng ka kakaretso li ke ke tsa finyella ka botlalo litlhoko tsa mekhoa e meng ea liroboto mabapi le theko, ts'ebetso, kopanyo le li-interfaces, sena se hlahisitse tlhokahalo ea theknoloji ea SoC (System on Chip) tsamaisong ea liroboto. Motlakase o kopantsoe le li-interfaces tse hlokahalang, tse ka nolofatsang moralo oa li-circuits tsa tsamaiso, ho fokotsa boholo ba tsamaiso, le ho fokotsa litšenyehelo. Mohlala, Actel e kopanya li-processor tsa NEOS kapa ARM7 lihlahisoa tsa eona tsa FPGA ho theha sistimi e felletseng ea SoC. Mabapi le balaoli ba theknoloji ea liroboto, lipatlisiso tsa eona li tsepamisitsoe haholo United States le Japane, 'me ho na le lihlahisoa tse hōlileng tsebong, tse kang American DELTATAU Company, Japan's Pengli Co., Ltd., joalo-joalo. Mookameli oa eona oa tsamaiso o nka theknoloji ea DSP e le eona mantlha mme e amohela sebopeho se bulehileng se thehiloeng ho PC. 4. Phello ea ho qetela Sephetho sa ho qetela ke karolo e amanang le motsoako oa ho qetela oa manipulator. Hangata e sebelisoa ho tšoara lintho, ho hokahana le mekhoa e meng le ho etsa mesebetsi e hlokahalang. Baetsi ba liroboto ka kakaretso ha ba rale kapa ha ba rekise lisebelisoa tsa ho qetela; maemong a mangata, ba fana feela ka gripper e bonolo. Hangata phello ea ho qetela e kenngoa holim'a 6-axis flange ea roboto ho phetha mesebetsi sebakeng se fanoeng, joalo ka welding, penta, gluing, le likarolo tsa ho kenya le ho laolla, e leng mesebetsi e hlokang hore liroboto li phethe.

Kakaretso ea li-motors tsa servo Mokhanni oa servo, eo hape a tsejoang e le "servo controller" le "servo amplifier", ke molaoli ea sebelisoang ho laola servo motors. Mosebetsi oa eona o tšoana le oa converter frequency ho li-motors tse tloaelehileng tsa AC, 'me ke karolo ea sistimi ea servo. Ka kakaretso, servo motor e laoloa ka mekhoa e meraro: boemo, lebelo le torque ho fihlela boemo bo nepahetseng ba sistimi ea phetisetso.

1. Sehlopha sa li-motors tsa servo E arotsoe ka mekhahlelo e 'meli: DC le AC servo motors.

Li-motors tsa AC servo li arotsoe hape ka li-motor tsa asynchronous servo le li-synchronous servo motors. Hajoale, litsamaiso tsa AC butle-butle li nkela lits'ebetso tsa DC sebaka. Ha ho bapisoa le litsamaiso tsa DC, li-motors tsa AC servo li na le melemo ea ho ts'epahala haholo, ho tima mocheso hantle, nako e nyane ea inertia, le bokhoni ba ho sebetsa tlasa khatello e phahameng. Hobane ha ho na borashe le likere tsa ho tsamaisa, sistimi ea servo ea AC le eona e fetoha sistimi e se nang brushless, 'me li-motor tse sebelisoang ho eona ke li-asynchronous motors tsa mofuta oa cage le li-motor synchronous tse sa feleng tse nang le sebopeho sa brushless. 1) Li-motors tsa servo tsa DC li arotsoe ka li-motors tse brushed le tse se nang brush

①Li-motors tse boreleli li na le theko e tlase, sebopeho se bonolo, torque e kholo ea ho qala, lebelo le pharalletseng, taolo e bonolo, e hloka ho lokisoa, empa ho bonolo ho e hlokomela (fetola borashe ba khabone), e hlahisa tšitiso ea motlakase, e na le litlhoko tikolohong ea ts'ebeliso, 'me hangata e sebelisetsoa taolo ya ditshenyehelo Maemo a hlokolosi a akaretsang a indasteri le a setjhaba;

②Li-motor tse se nang brush li nyane ka boholo le boima bo bobebe, li na le tlhahiso e kholo le karabelo e potlakileng. Li na le lebelo le phahameng le inertia e nyenyane, torque e tsitsitseng le ho potoloha hamonate. Taolo e rarahane ebile e bohlale. Mokhoa oa ho fetisoa oa elektroniki oa fetoha. E ka tsamaea ka square wave kapa sine wave. Enjene ha e hlokomeloe ebile e sebetsa hantle. Ho boloka matla, mahlaseli a manyane a motlakase, ho phahama ha mocheso o tlase le bophelo bo bolelele, tse loketseng libaka tse fapaneng.

2. Litšobotsi tsa mefuta e sa tšoaneng ea likoloi tsa servo

1) Melemo le bofokoli ba DC servo motor Melemo: taolo e nepahetseng ea lebelo, torque e thata haholo le litšobotsi tsa lebelo, molao-motheo o bonolo oa taolo, ho bonolo ho e sebelisa, le theko e tlase. Mefokolo: phetisetso ea borashe, moeli oa lebelo, khanyetso e eketsehileng, tlhahiso ea likaroloana tsa ho roala (ha li loketse libaka tse se nang lerōle le tse phatlohang)

2) Melemo le bofokoli ba AC servo motor Melemo: litšoaneleho tse ntle tsa taolo ea lebelo, taolo e boreleli sebakeng sohle sa lebelo, hoo e batlang e se na oscillation, ts'ebetso e phahameng ea ho feta 90%, tlhahiso e fokolang ea mocheso, taolo ea lebelo le phahameng, taolo e nepahetseng ea boemo bo holimo (ho latela ho nepahala ha encoder), e lekantsoeng. sebaka sa ts'ebetso Ka hare, e ka finyella torque e sa khaotseng, inertia e tlaase, lerata le tlaase, ho se roale borashe, le ho hloka tlhokomelo (e loketseng libaka tse se nang lerōle le tse phatlohang). Mefokolo: Taolo e rarahane ho feta, liparamente tsa mokhanni li hloka ho lokisoa sebakeng sa marang-rang mme li-parameter tsa PID li behiloe, 'me likhokahano tse ling lia hlokahala. Hona joale, li-drive tsa servo tse tloaelehileng li sebelisa li-digital signal processors (DSP) e le setsi sa taolo, se ka kenyang ts'ebetsong mekhoa e rarahaneng ea ho laola le ho finyella digitization, marang-rang le bohlale. Lisebelisoa tsa motlakase ka kakaretso li sebelisa li-circuits tsa drive tse etselitsoeng li-module tsa matla a bohlale (IPM) joalo ka mantlha. IPM e kopanya potoloho ea koloi 'me e na le li-circuits tsa ho lemoha le ho sireletsa tse kang overvoltage, overcurrent, overheating, le undervoltage. Software e boetse e eketsoa ho potoloho e kholo. Qala potoloho ho fokotsa tšusumetso ea ts'ebetso ea ho qala ho mokhanni. Yuniti ea ho khanna motlakase e qala ka ho lokisa matla a motlakase a mekhahlelo e meraro kapa matla a mantlha ka potoloho ea mekhahlelo e meraro ea borokho bo felletseng ho fumana motlakase o tobileng o tsamaisanang le ona. Matla a lokisitsoeng a mekhahlelo e meraro kapa a mains a ntan'o fetoloa khafetsa ka sefetoleli sa motlakase sa sinusoidal PWM sa methati e meraro ho khanna mochini o sa feleng oa magnet synchronous AC servo motor. Ts'ebetso eohle ea yuniti ea ho khanna matla e ka boleloa feela hore ke ts'ebetso ea AC-DC-AC. Potoloho ea mantlha ea yuniti ea rectifier (AC-DC) ke potoloho e sa laoleheng ea borokho bo felletseng ba mekhahlelo e meraro.

Pono e phatlohileng ea "haronic reducer". Ho nkile Khampani ea Japane ea Nabtesco lilemo tse 6-7 ho tloha ho sisinya moralo oa RV mathoasong a lilemo tsa bo-1980 ho fihlela katleho e kholo liphuputsong tse fokotsang RV ka 1986; le Nantong Zhenkang le Hengfengtai, bao e bileng bona ba pele ba ho hlahisa litholoana Chaena, le bona ba ile ba qeta nako. 6-8 lilemo. Na ho bolela hore likhoebo tsa rona tsa lehae ha li na menyetla? Litaba tse monate ke hore ka mor'a lilemo tse 'maloa tsa ho romelloa, lik'hamphani tsa Machaena li se li entse tsoelo-pele e itseng.

*Sengoloa se hlahisitsoe Marang-rang, ka kopo ikopanye le rona bakeng sa ho hlakola tlolo ea molao.

Nako ea poso: Sep-15-2023