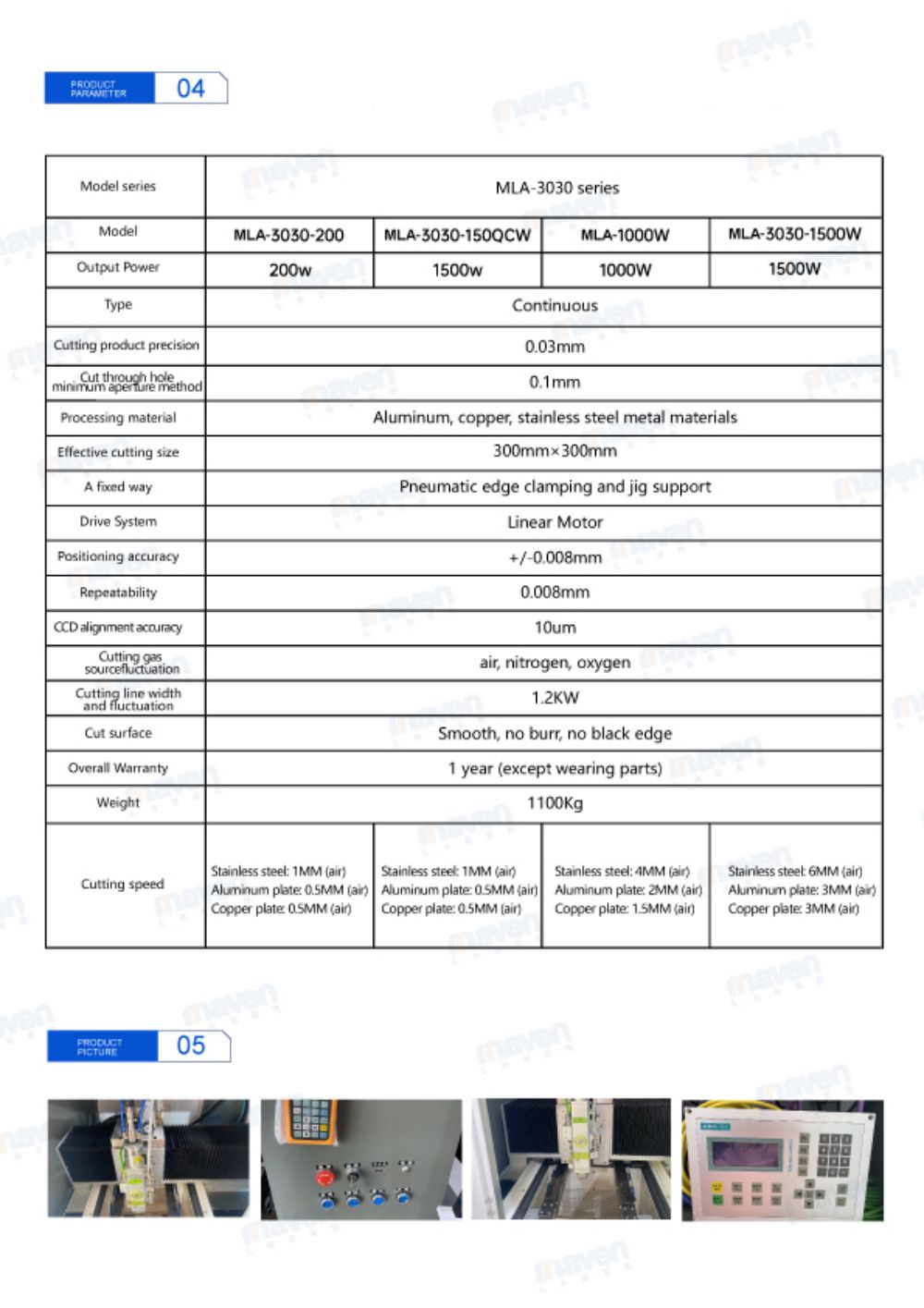

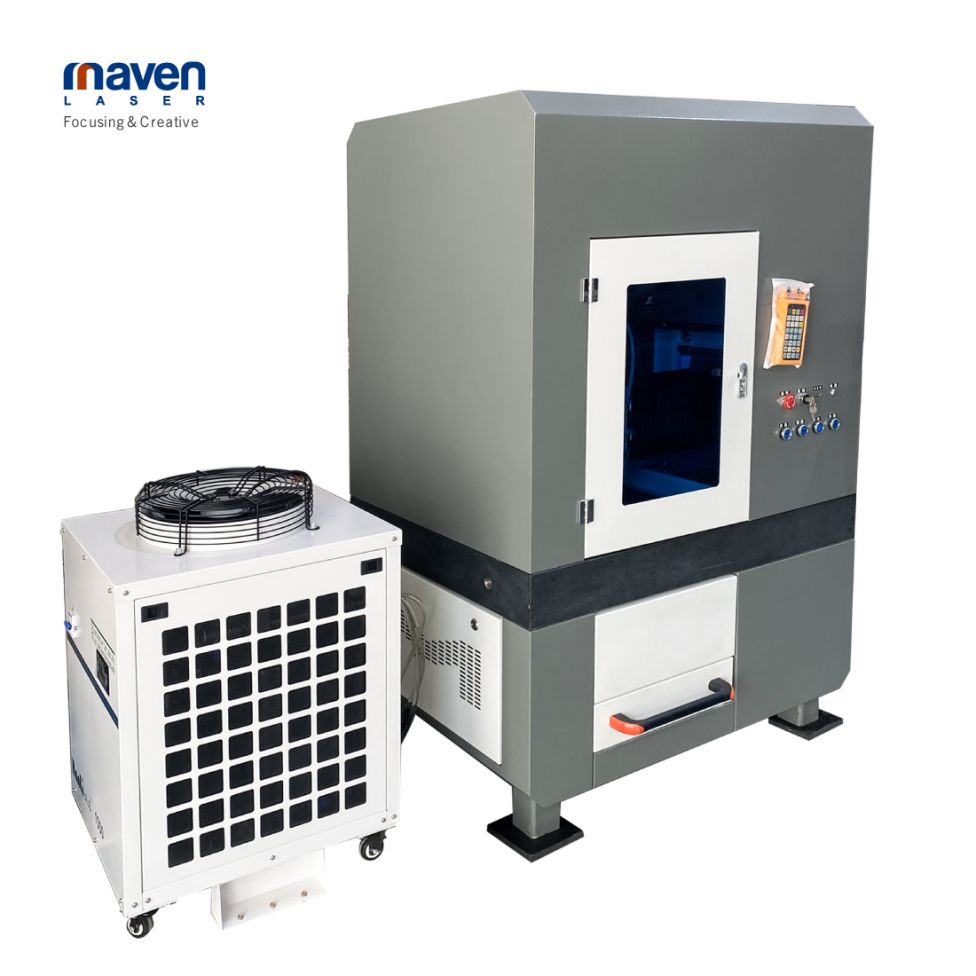

Fiber Laser Cutting Machine-MLA 3030 Series

TLHALOSO EA SEHLAHISOA

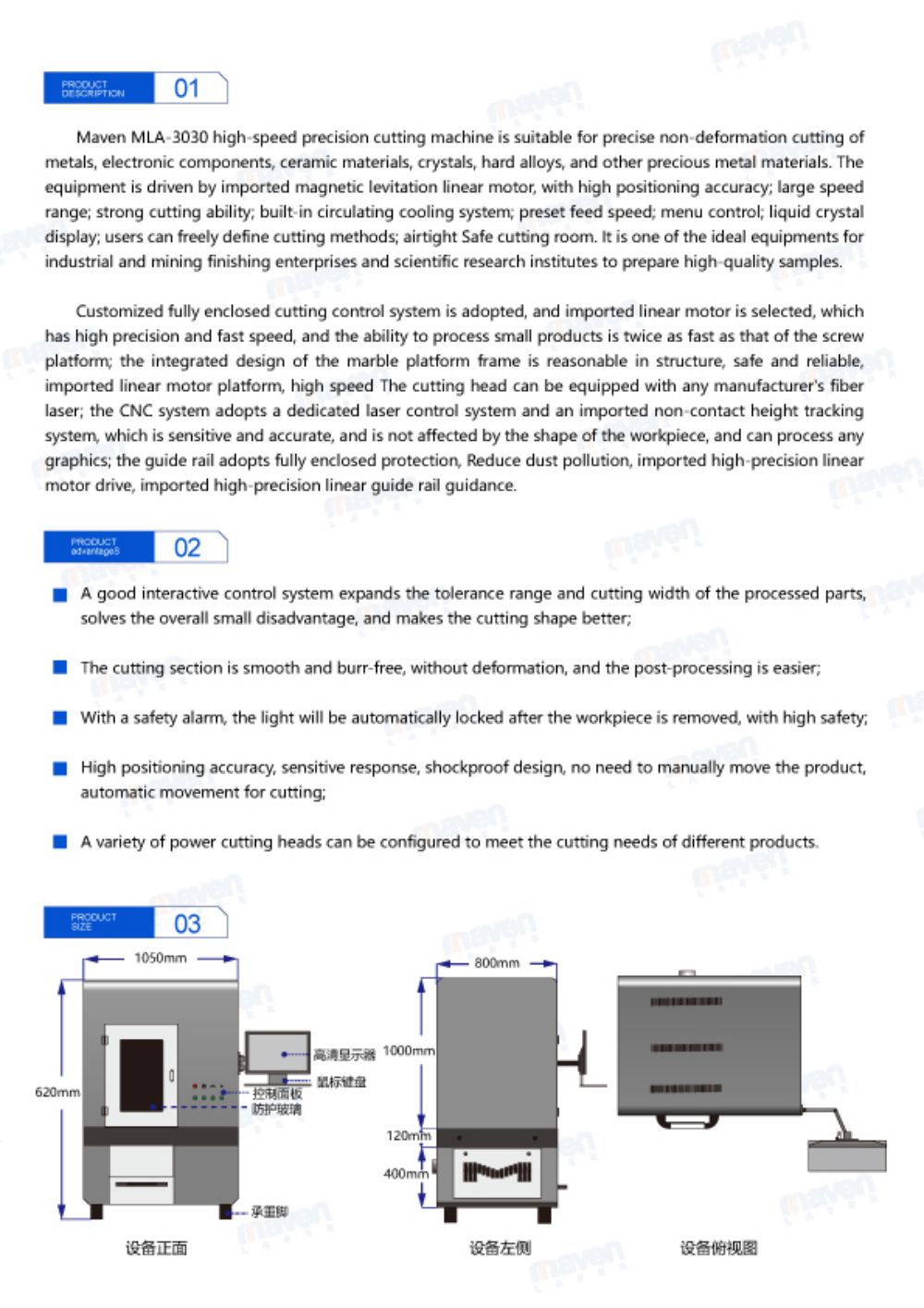

Maven MLA-3030mochini o sehang ka lebelo le holimoe loketse ho itšeha ka mokhoa o nepahetseng oa tšepe, likarolo tsa elektroniki, lisebelisoa tsa ceramic, likristale, li-alloys tse thata le lisebelisoa tse ling tsa bohlokoa tsa tšepe. Thepa e khannoa ke enjene e tsoang kantle ho naha ea magnetic levitation linear, e nang le boemo bo holimo bo nepahetseng; lebelo le leholo la lebelo; matla a ho itšeha; tsamaiso ea ho pholisa e potolohang e hahelletsoeng ka hare; lebelo la phepelo e behiloeng esale pele; taolo ya menu; pontšo ea kristale ea metsi; basebelisi ba ka hlalosa ka bolokolohi mekhoa ea ho itšeha; kamore e sireletsehileng ea ho itšeha. Ke e 'ngoe ea lisebelisoa tse loketseng bakeng sa likhoebo tsa indasteri le tsa merafo le litsi tsa lipatlisiso tsa mahlale ho lokisa lisampole tsa boleng bo holimo.

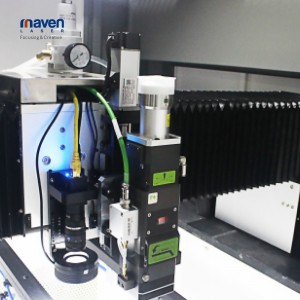

Sistimi e hlophisitsoeng e kentsoeng ka botlalo ea ho itšeha e amoheloa, 'me ho khethoa enjene ea mela e tsoang kantle ho naha, e nang le ho nepahala ho phahameng le lebelo le potlakileng, mme bokhoni ba ho sebetsana le lihlahisoa tse nyane bo potlakile habeli ho feta ba sethala sa screw; moralo o kopantsoeng oa foreimi ea sethala sa 'mabole o utloahala ka sebopeho, o bolokehile ebile o ka tšeptjoa, o romelloa kantle ho naha ka lebelo le phahameng Hlooho ea ho itšeha e ka hlomelloa ka laser fiber efe kapa efe ea moetsi; Sistimi ea CNC e amohela sistimi e inehetseng ea taolo ea laser le sistimi ea ho latedisa bophahamo ba batho ba kantle ho naha, e nang le kutloelo-bohloko le e nepahetseng, mme ha e amehe ke sebopeho sa mosebetsi, mme e ka sebetsana le litšoantšo life kapa life; seporo se nka tšireletso e koetsoeng ka ho feletseng, Fokotsa tšilafalo ea lerōle, koloi e tsamaeang ka mokhoa o nepahetseng e tsoang linaheng tse ling, tataiso ea terene e nepahetseng e tsoang linaheng tse ling.

MELEMO EA SEHLAHISO

Sistimi e ntle ea taolo e sebetsanang e eketsa lebelo la mamello le ho itšeha bophara ba likarolo tse sebetsitsoeng, e rarolla bothata bo nyane ka kakaretso, 'me e etsa hore sebopeho sa ho itšeha se be betere;

Karolo ea ho itšeha e boreleli ebile ha e na burr, ntle le deformation, 'me post-processing e bonolo;

Ka alamo ea tšireletso, lebone le tla koaloa ka bohona ka mor'a hore sesebelisoa sa mosebetsi se tlosoe, se be le tšireletso e phahameng;

Ho nepahala ha boemo bo phahameng, karabelo e hlokolosi, moralo o sa tsitsang, ha ho na tlhoko ea ho tsamaisa sehlahisoa ka letsoho, motsamao oa othomathike bakeng sa ho itšeha;

Lihlooho tse fapaneng tsa ho itšeha matla li ka hlophisoa ho fihlela litlhoko tsa ho itšeha tsa lihlahisoa tse fapaneng.

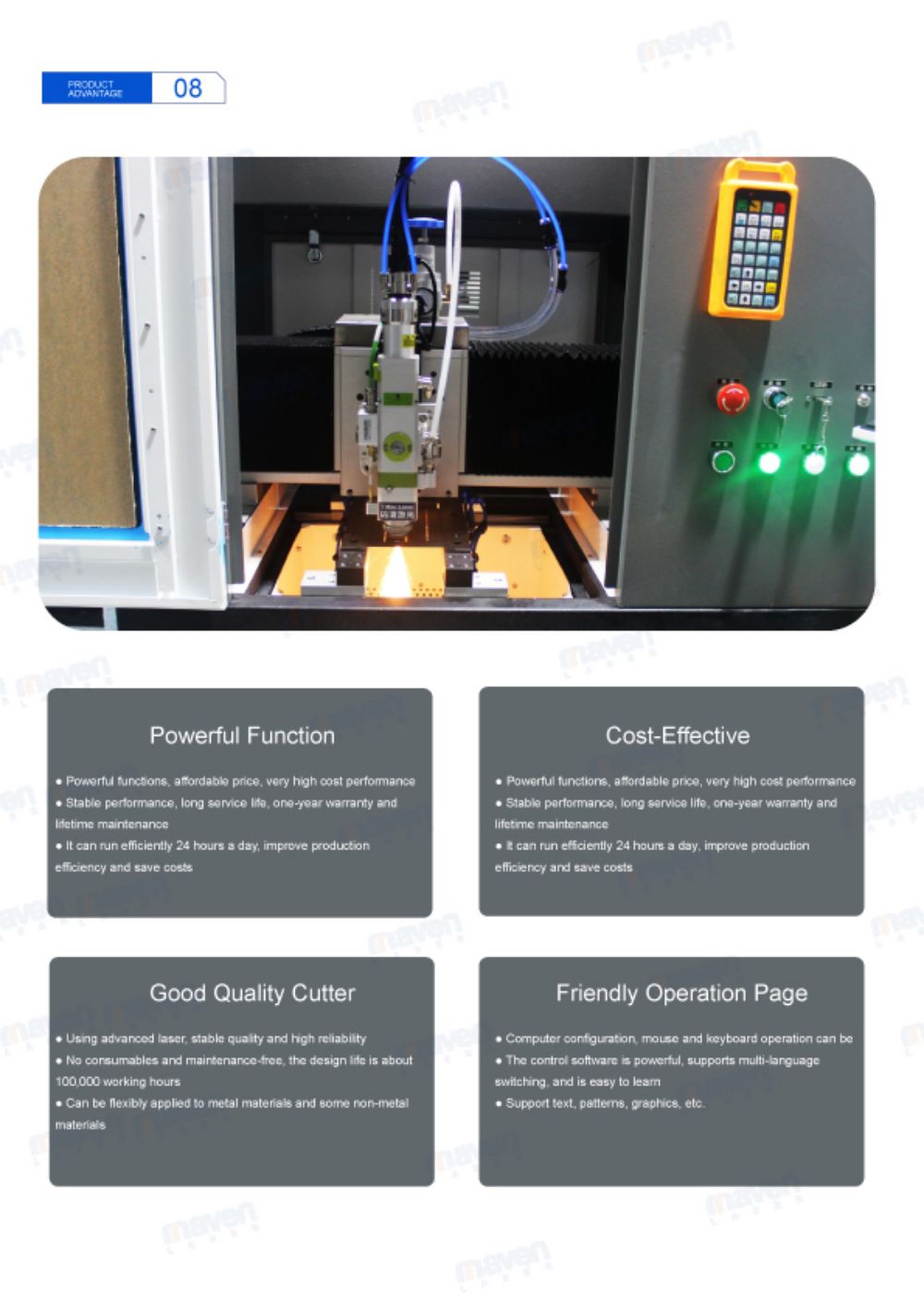

Mosebetsi o Matla

● Mesebetsi e matla, theko e theko e tlaase, ts'ebetso ea theko e phahameng haholo

● Ts'ebetso e tsitsitseng, bophelo bo bolelele ba tšebeletso, tiisetso ea selemo se le seng le tlhokomelo ea bophelo bohle

● E ka sebetsa hantle lihora tse 24 ka letsatsi, ea ntlafatsa katleho ea tlhahiso le ho boloka litšenyehelo

Chelete e sebetsang

● Mesebetsi e matla, theko e theko e tlaase, ts'ebetso ea theko e phahameng haholo

● Ts'ebetso e tsitsitseng, bophelo bo bolelele ba tšebeletso, tiisetso ea selemo se le seng le tlhokomelo ea bophelo bohle

● E ka sebetsa hantle lihora tse 24 ka letsatsi, ea ntlafatsa katleho ea tlhahiso le ho boloka litšenyehelo

Sekhabi sa boleng bo botle

● Ho sebelisa laser e tsoetseng pele, boleng bo tsitsitseng le ho tšepahala ho phahameng

● Ha ho na lintho tse ka sebelisoang ebile ha li na tlhokomelo, bophelo ba moralo bo ka ba lihora tse 100,000 tsa ho sebetsa

● E ka sebelisoa habonolo linthong tsa tšepe le linthong tse ling tseo e seng tsa tšepe

Leqephe la Ts'ebetso ea Setsoalle

Lebelo le Phahameng la ho Seha Hlooho

Hlooho ea ho itšeha ka lebelo le phahameng, sefate se tsitsitseng le se matla, lebelo la ho itšeha ka potlako, boleng bo botle ba ho itšeha, deformation e nyane, ponahalo e boreleli le e ntle;

Tsepamiso e ka fetoloa ka bo eona le ka nepo ho latela botenya ba thepa, ho itšeha ka lebelo le phahameng, nako ea ho boloka.

Boleng bo botle bo botle, sefate se ka tsepamisoa haufi le moeli oa diffraction ho finyella machining e nepahetseng.E ka tšeptjoang, modular all-fiber design.

Sistimi ea Pholiso ea Ts'ebetso e Phahameng

Sistimi ea ho pholisa e sebetsang hantle haholo e nka mochini o pholileng o sebetsang hantle haholo, 'me o fumana ts'ebetso e phahameng ka ho sebelisa sefahla sa ho atolosa mocheso.

Ts'ebetso ea boleng bo phahameng e tlase ea lerata.

Magnetic levitation linear motor

Screw slide module, ho nepahala ha maemo a holimo, lebelo le potlakileng, ho khutsa le ho tsitsa, ho boloka chelete e ngata.