Mochini oa ho tjheseletsa oa Laser oa Robotic Fiber

Lisebelisoa:

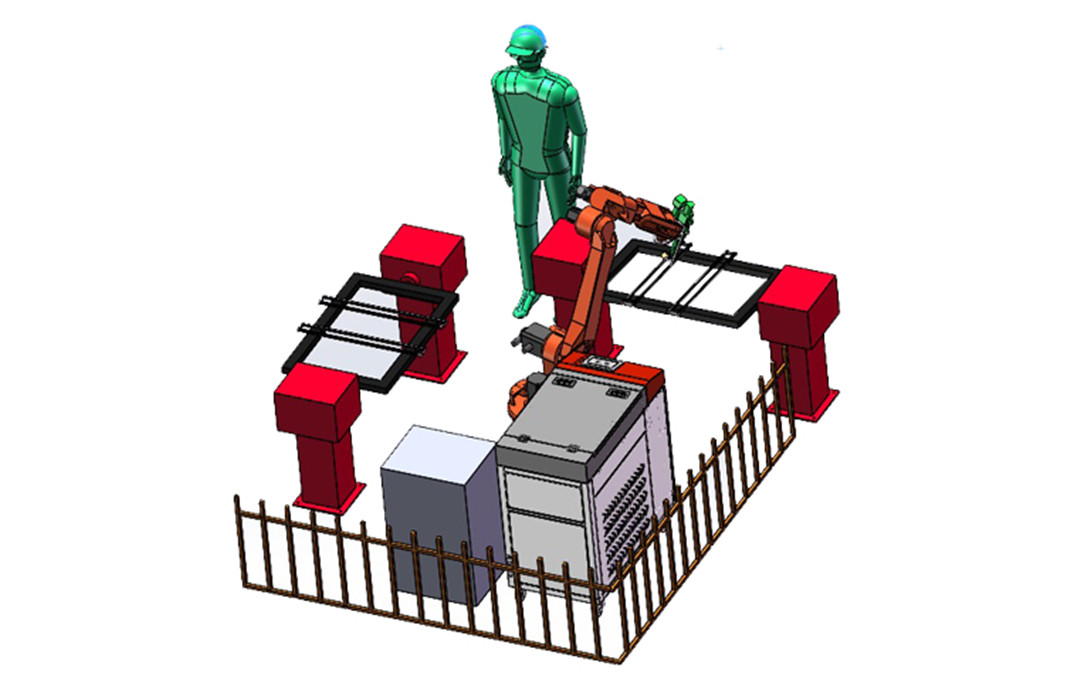

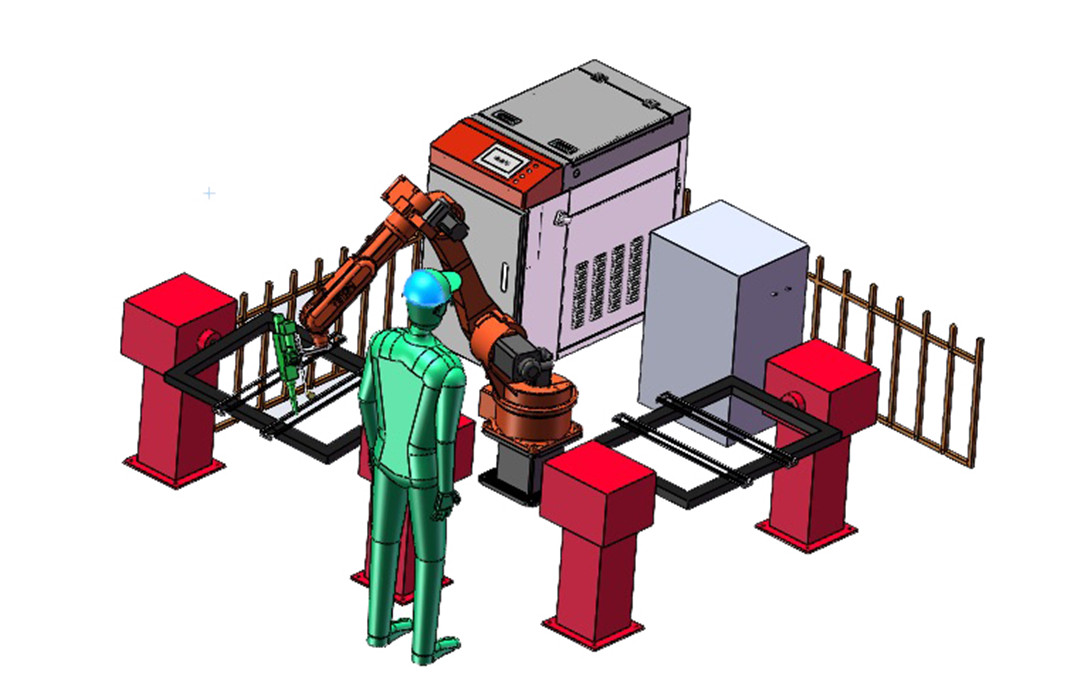

1. Ho sebelisa motsamao oa liroboto, o loketseng sebaka se seholo sa tjheseletsa, e ka ba khokahano ea li-axis tse tšeletseng.

2. Na tjheseletsa sebakeng leha e le efe, ka sebele hlokomela othomathiki tjheseletsa leha e le efe trajectory sebakeng.

3. Ho nepahala ho pheta-pheta ho phahameng, ho ka pheta-pheta ho tjheseletsa ka makhetlo a mangata ntle le phoso, boleng ba weld bo tsitsitse haholoanyane.

4. E ka nka sebaka sa tshebetso pukwanana, 'me ka laser weld masimo a rarahaneng le kotsi.

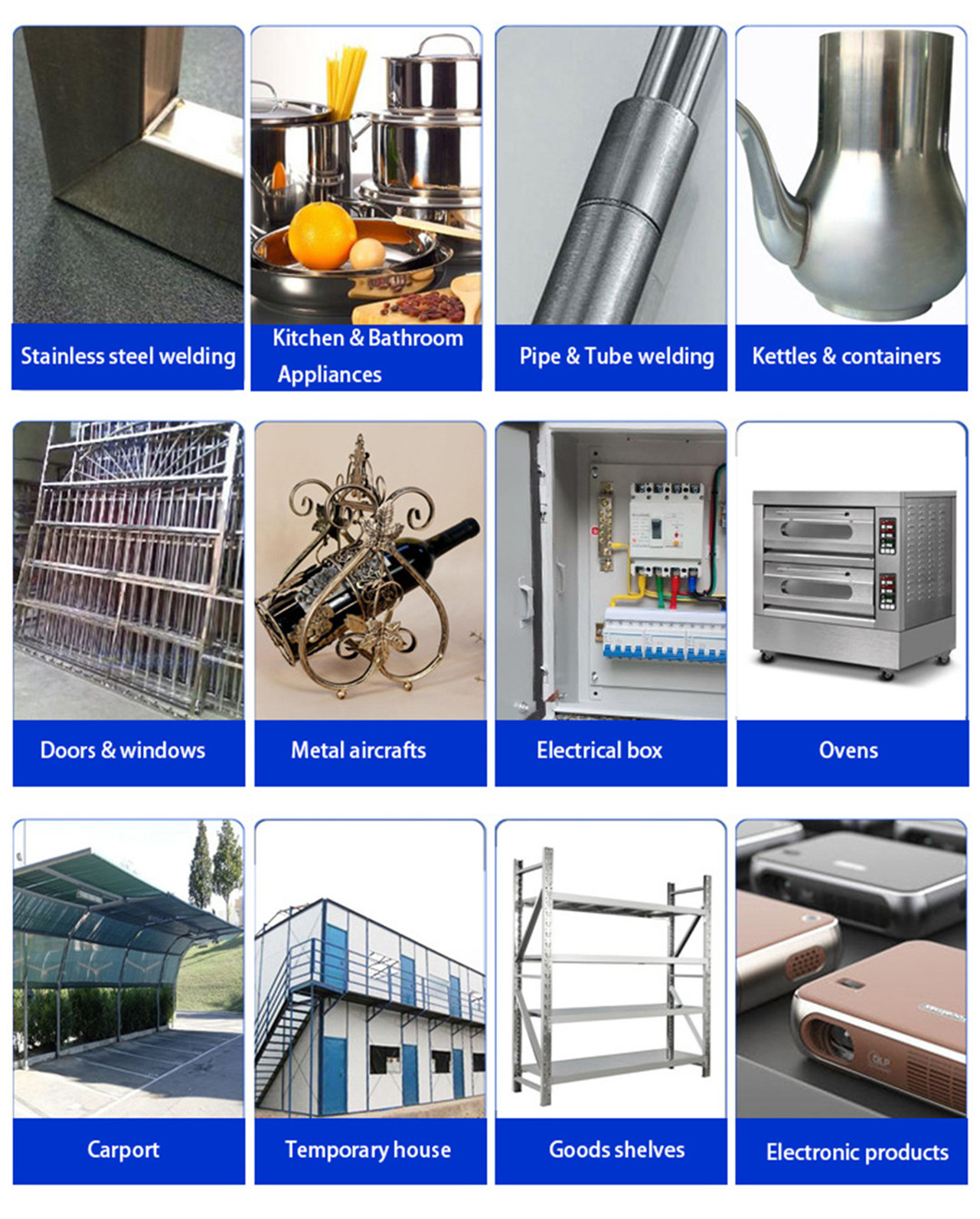

Libaka tsa kopo:

'Mele oa koloi, poleiti ea tšepe ea koloi, poleiti ea clutch, masimo a thata le a rarahaneng a ho tjheseletsa, likaroloana tsa microelectronic, likarolo tse nepahetseng, likarolo tsa digital tsa boemo bo phahameng, li-connectors fiber optic, lisebelisoa tsa bongaka, hlobo e kholo ea hlobo, ho bōpa ente le tse ling.

TS'ELISO THAROLLO

Wire Feeder le Welding E Tsepamisitsoe ho Taolo ea Pedal

0.08mm Positioning Positioning Ho nepahala

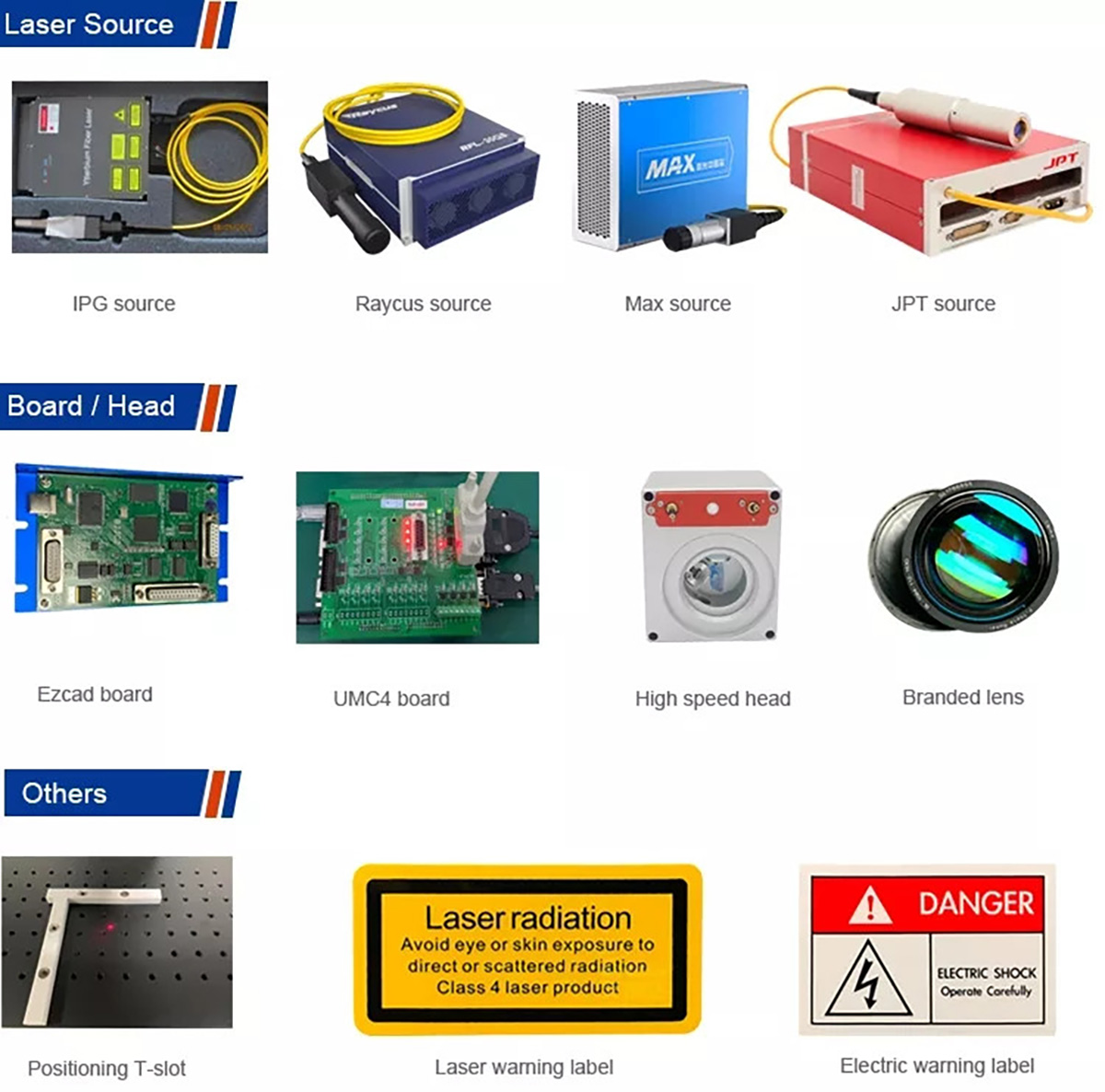

Raycus Max JPT IPG Mohloli oa Laser oa Khetho

Customization ea Whole System

| Lebitso la Sehlahiswa | Mochini oa Welding oa Laser oa RobotoMLA-W-A01 |

| Wavelength | 1070+/-10 nm |

| Matla a Laser | 1000W 1500W 2000W 3000W |

| Phetoho ea Matla | 10-100% |

| Bolelele ba Fiber | Standard 10m kapa Hlalosa |

| Mekhoa ea ho sebetsa | CW/Pulse |

| Lebelo la Lebelo | 0-120 limilimithara |

| Botenya ba Weld | 0.5-6 limilimithara |

| Tlhokahalo ea Lekhalo la Welding | <1 limilimithara |

| Modulation Frequency | 20KHZ |

| Bulela/tima Nako | 20 Rona |

| Mocheso oa Mosebetsi | 15-35 ℃ |

| Phepelo ea motlakase | 220V/50HZ/30A |

| Mekhoa ea ho phomola | Metsi a pholileng a kentsoeng |

| Boholo ba Mochini | 990*540*1030 limilimithara |

BONOLO SEBELISA

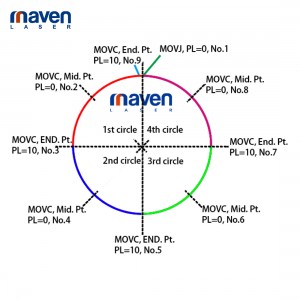

Selaoli sa tšebeliso ea botsoalle bakeng sa tšebelisano e bonolo le litaelo tsa mosebetsi oa fiber laser welding

TAOLI TS'ELISO

Khokahano ea khabinete ea taolo ke ho laola ts'ebetso ea ho fepa ka terata. 'Me matla a laser a ka nyoloha' me a oa butle ho thibela ho chesa ho feta. Ho phahama butle le ho oa ho molemo ka ho khetheha bakeng sa tjheseletsa ea poleiti e tšesaane. Ha manipulator e qeta, hangata ho bonolo ho e tšela ka poleiti.

TS'ELISO TS'OANELO

Ntle le ho lokisa li-parameter tsa welding tsamaisong ea laser. E boetse e na le mesebetsi ea leseli le leng le le leng la boemo ba sistimi, phetoho ea metsi a motlakase, le khopotso ea othomathiki ho sireletsa lense.

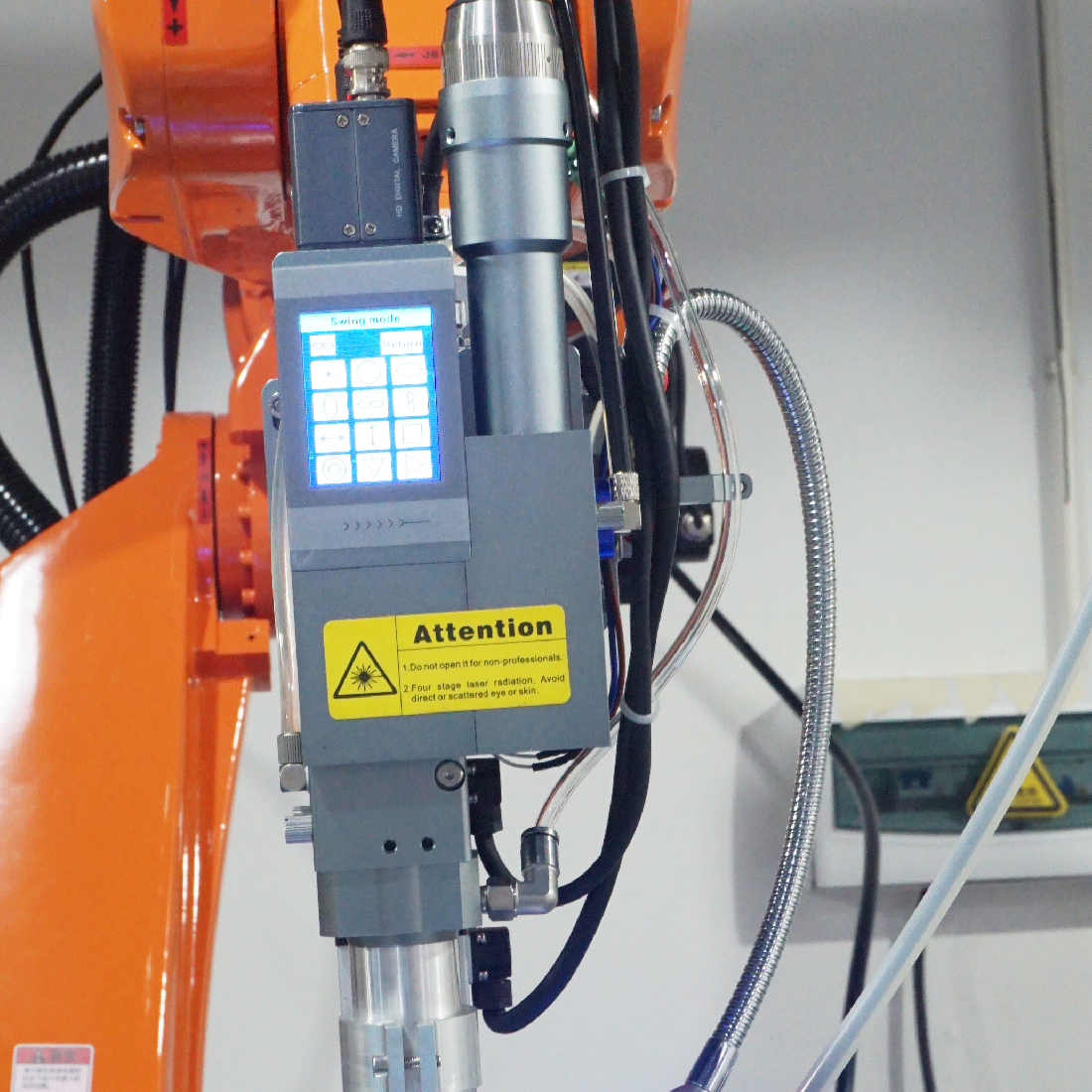

TSOHLE HLOOHO

Hlooho e kopantsoeng ea welding, CCD hloohong, matla a feto-fetohang, ho tsepamisa mohopolo, ts'ebetso e bonolo.

BONOLO SEBELISA

Likonopo tsa pendant ea ho ruta li bonolo ebile li bonolo ho utloisisa, 'me lenaneo la ho ruta le ka ithutoa le ho sebelisoa kapele. Haeba ts'ebetso e fosahetse, mochini o emisa ka bohona ho qoba kotsi ea tšenyo ea lisebelisoa.

SEBELISA KA KHAHLE

Ha e se e hlophisitsoe, e ka sebelisoa ka linako tsohle. MavenLaser Robot Arm e ts'ehetsa lihora tse 24 tsa mosebetsi o tsoelang pele ka nepo le lebelo le holimo. Ts'ebetso e ikemetseng ka botlalo, roboto e ka phethela mosebetsi oa batho ba fetang 2-3 ka letsatsi.

THEKO E TLASE

Matsete a nako e le 'ngoe, melemo ea nako e telele. Bophelo ba ts'ebeletso ea roboto ea MavenLaser ke lihora tse 80,000, tse lekanang le lilemo tse fetang 9 tsa mosebetsi o sa sitisoeng oa lihora tse 24. E boloka haholo litšenyehelo tsa basebetsi le litšenyehelo tsa tsamaiso ea basebetsi, 'me e rarolla mathata a kang bothata ba ho hira batho.

POLOKO LE TŠEPANG

Letsoho la roboto la MavenLaser le na le mehato ea ts'ireletso ea photoeletric. Ha lintho tse tsoang kantle ho naha li kena sebakeng sa mosebetsi, li ka lla le ho emisa mosebetsi ho qoba kotsi ho mosebeletsi.

PHEPHANG MATLA LE KHOTSO

Sebopeho sa mochini oa mochini oa MavenLaser se bonolo ebile se makhethe, ha ho lerata, letsoho le bobebe le matla la roboto, tšebeliso e tlase ea matla, saxing ea matla le ts'ireletso ea tikoloho.

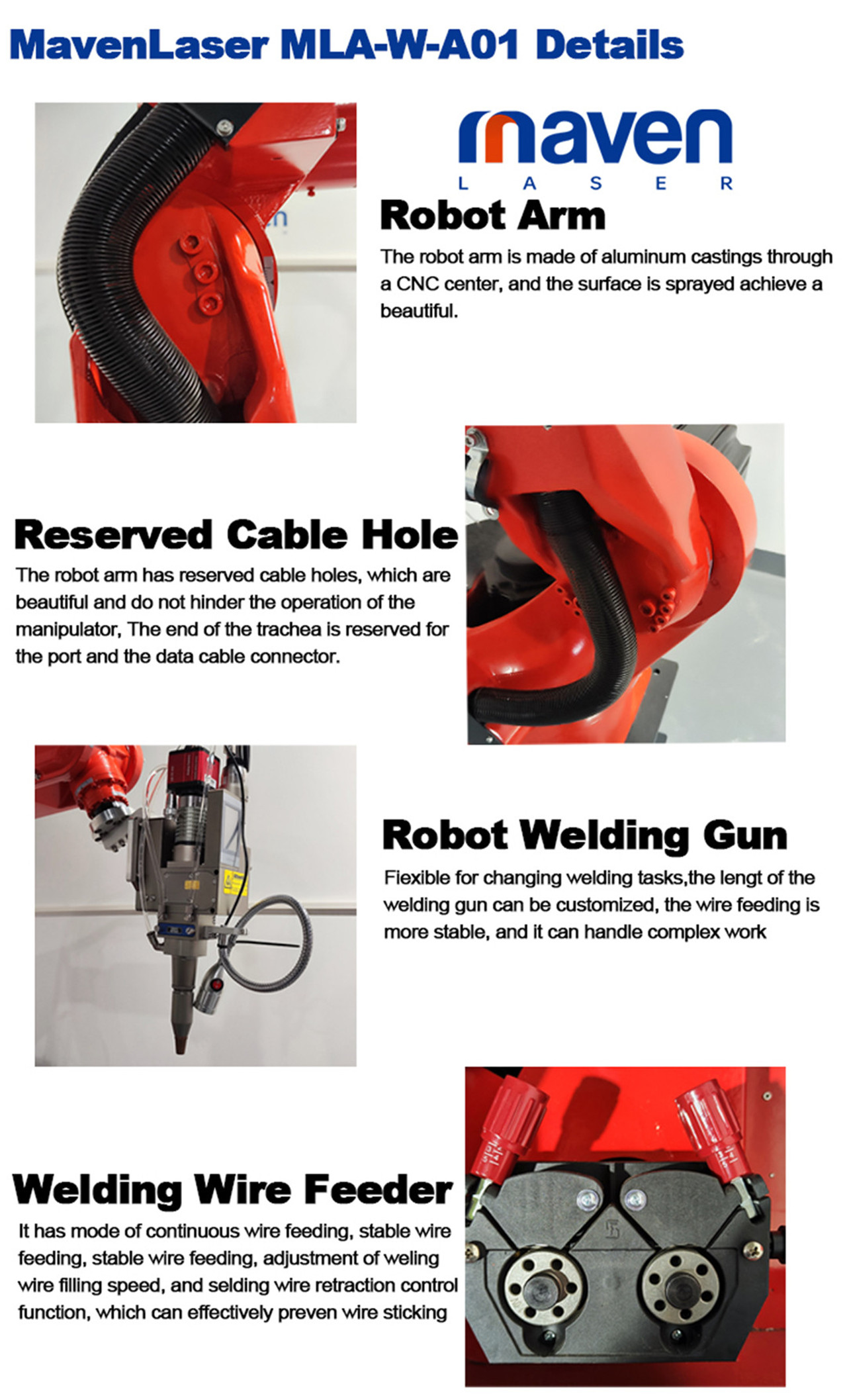

Roboto Arm

Letsoho la roboto le entsoe ka li-castings tsa aluminium ka setsi sa CNC, 'me bokaholimo bo fafatsoa bo fihlela botle.

Reserved Cable Hole

Letsoho la roboto le bolokile likoti tsa cable, tse ntle 'me nit li sitisa ts'ebetso ea manipulator, pheletso ea trachea e boloketsoe koung le sehokelo sa thapo ea data.

Roboto Welding Sethunya

E feto-fetoha bakeng sa ho fetola mesebetsi ea welding, bolelele ba sethunya sa welding bo ka etsoa ka mokhoa o ikhethileng, ho fepa ka terata ho tsitsitse haholoanyane, 'me ho ka sebetsana le mosebetsi o rarahaneng.

Welding Wire Feeder

E na le mokhoa oa ho fepa ka terata e tsoelang pele, ho fepa ka terata e tsitsitseng, ho fepa ka terata e tsitsitseng, ho lokisa lebelo la ho tlatsa terata, le ts'ebetso ea taolo ea ho khutlisa mohala, e ka thibelang ho ts'oaroa ha terata ka nepo.

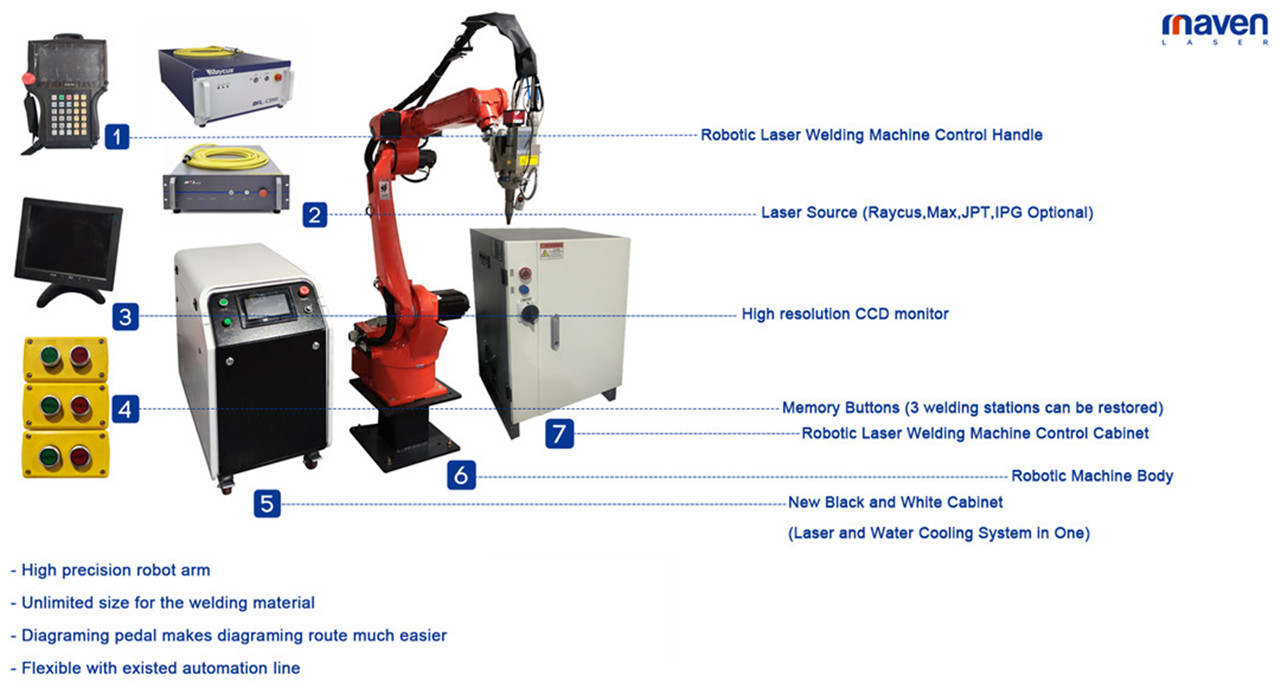

● Mohloli oa Laser(Raycus,Max,JPT,IPG Optional)

● Sesebelisoa se phahameng sa CCD

● Likonopo tsa Memori(liteishene tse 3 tsa ho cheseletsa li ka khutlisoa)

● Khabinete e Ncha e Ntšo le Bosoeu(Laser le Metsi Cooling System in One)

● 'Mele oa Mochini oa Liroboto

● Khabinete ea Taolo ea Mochini oa Robotic Laser Welding

● Letsoho la roboto le nepahetseng haholo

● Boholo bo sa lekanyetsoang bakeng sa lisebelisoa tsa welding

● Pedali ea ho etsa litšoantšo e nolofaletsa tsela ea ho etsa litšoantšo

● E feto-fetoha le mohala o teng oa othomathike

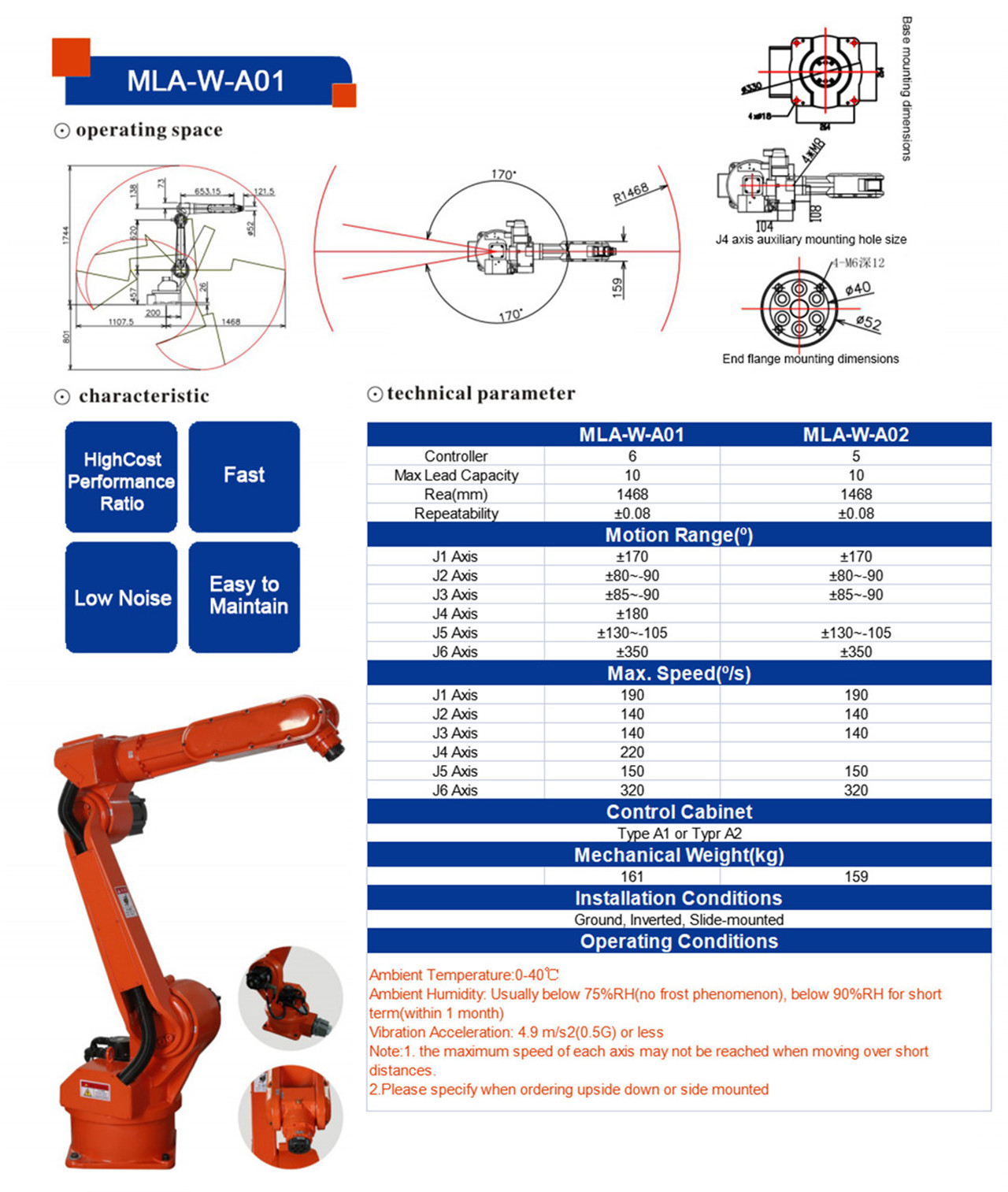

| MLA-W-A01 | MLA-WA02 | |

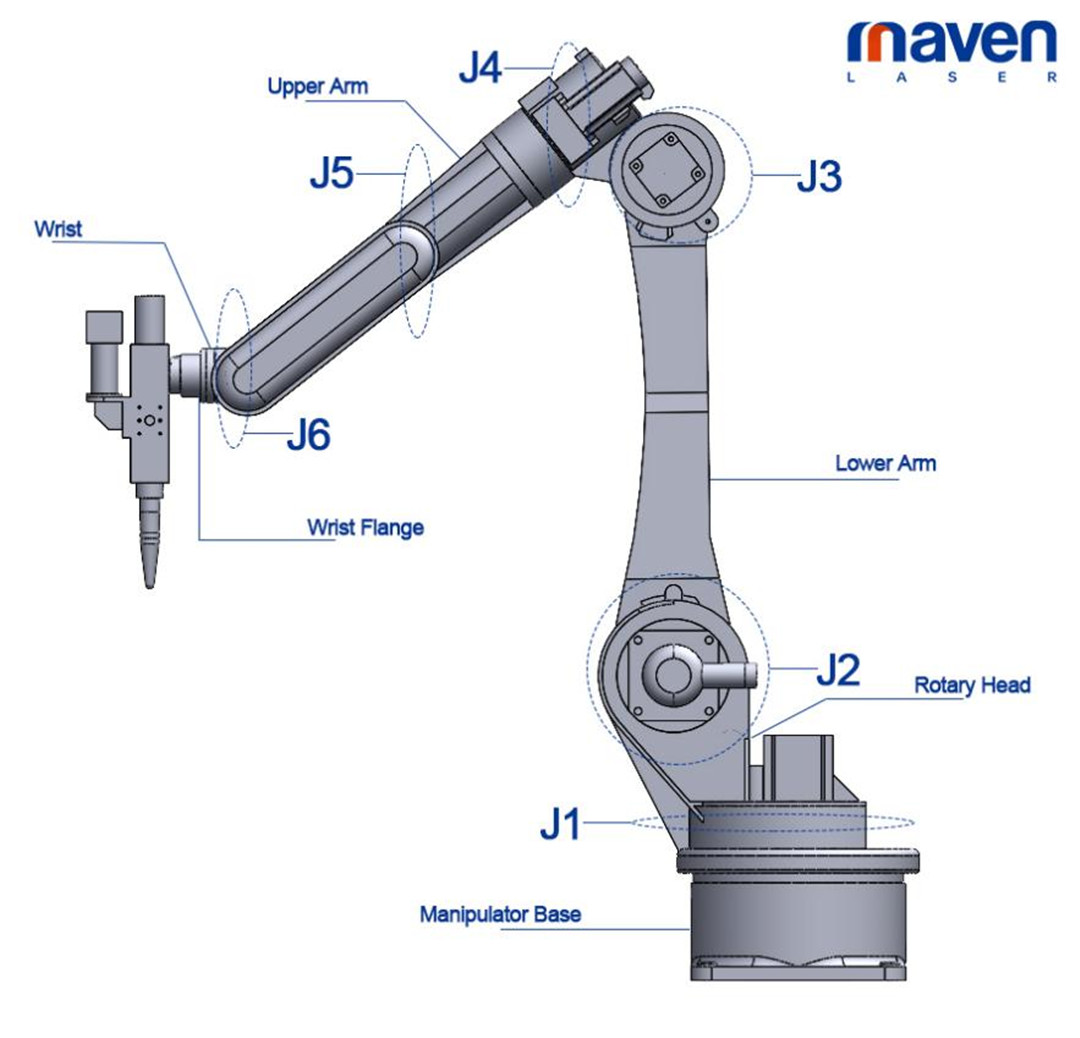

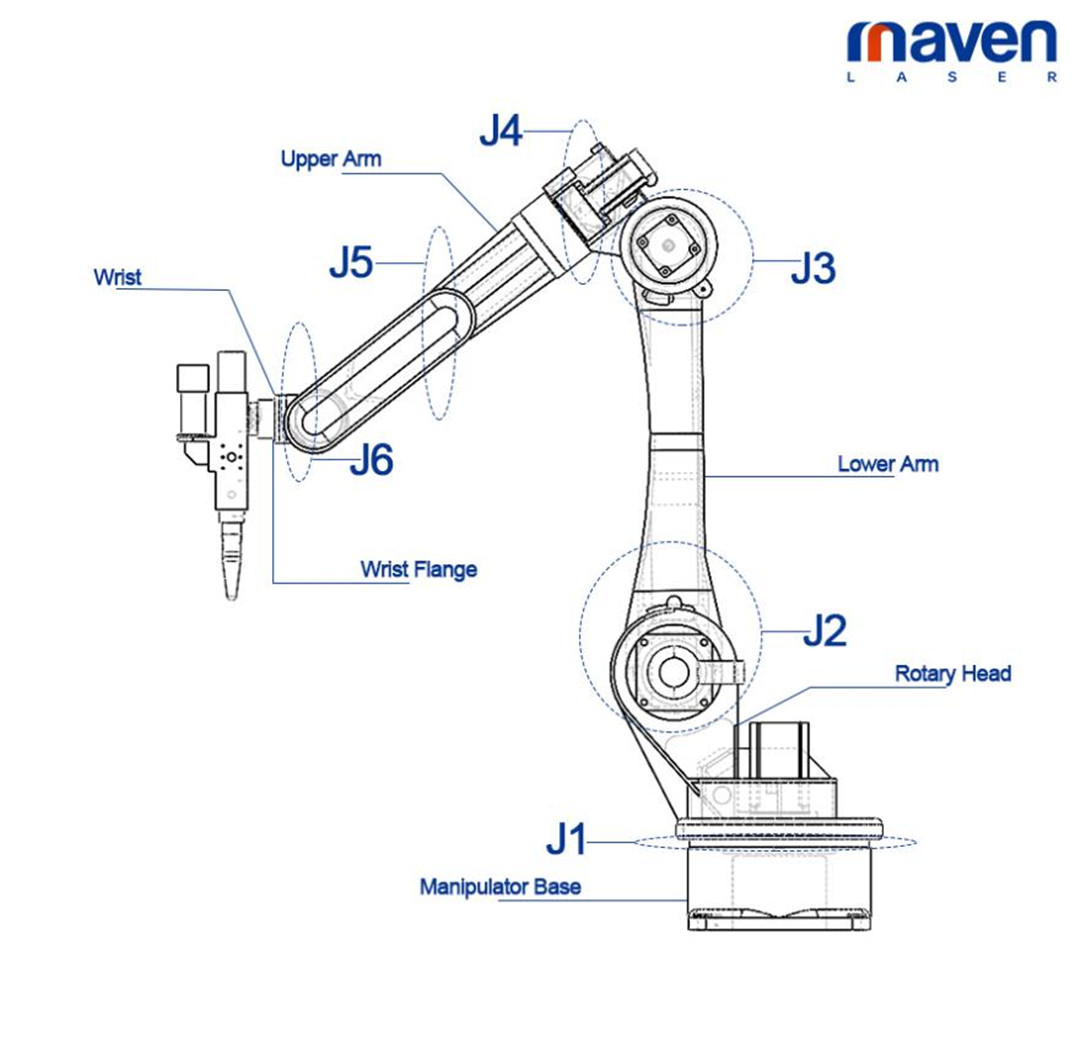

| Molaoli | 6 | 5 |

| Bokhoni ba ho etella pele bo phahameng | 10 | 10 |

| Rea(mm) | 1468 | 1468 |

| Pheta-pheta | ±0.08 | ±0.08 |

| Motion Range(°) | ||

| J1 Axis | ± 170 | ± 170 |

| J2 Axis | ±80~-90 | ±80~-90 |

| J3 Axis | ± 85 ~-90 | ± 85 ~-90 |

| J4 Axis | ±180 |

|

| J5 Axis | ± 130~-105 | ± 130~-105 |

| J6 Axis | ± 350 | ± 350 |

| Max. Lebelo(°/s) | ||

| J1 Axis | 190 | 190 |

| J2 Axis | 140 | 140 |

| J3 Axis | 140 | 140 |

| J4 Axis | 220 |

|

| J5 Axis | 150 | 150 |

| J6 Axis | 320 | 320 |

| Kabinete ea Taolo | ||

| Mofuta oa A1 kapa Mofuta oa A2 | ||

| Boima ba Mechini(kg) | ||

|

| 161 | 159 |

| Maemo a Tlhophiso | ||

| Fatše, E Kenyelelitsoe, E kentsoe ka li-slide | ||

| Maemo a Tshebetso | ||

Ambient Mocheso:0-40℃

Mongobo o Ambient: Hangata o ka tlase ho 75%RH(ha ho serame), ka tlase ho 90%RH ka nako e khuts'oane (ka nako ea khoeli e le 1)

Ho Potlakisa Vibration::4.9 m/s2(0.5G) kapa ka tlase ho moo

Tlhokomeliso: 1. lebelo le phahameng la axis ka 'ngoe le ka 'na la se ke la finyelloa ha le tsamaea libakeng tse khutšoanyane.

2.Ka kopo, hlakisa ha u laela ka holimo kapa ka lehlakoreng le behiloeng

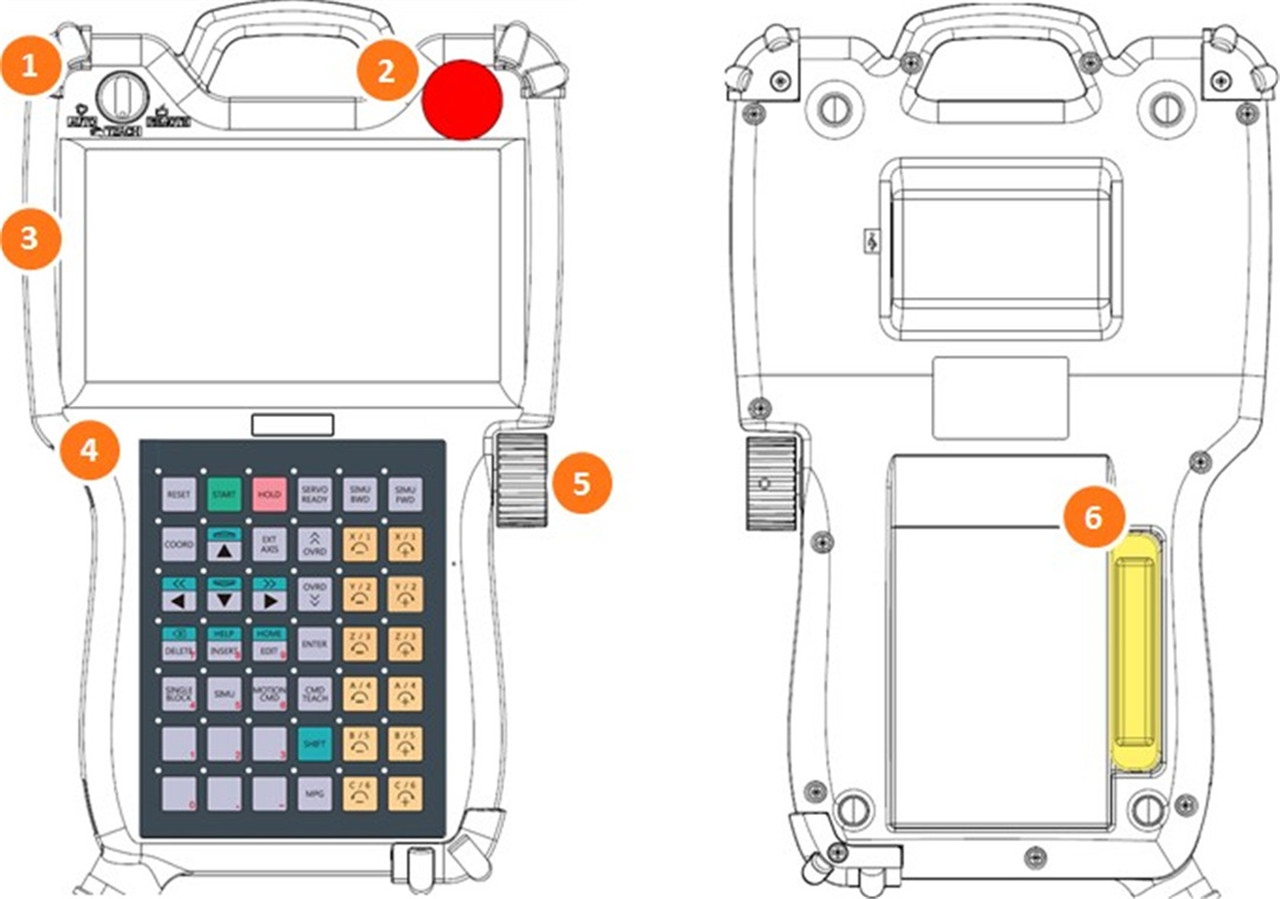

1. Mokhoa oa ho fetola

2. Emergency Stop

3. Skrine sa Pontšo

4. Linotlolo Tsa 'Meleng

5. MPG (Manuel Pulse Jenereithara)

6. Ho nolofalletsa Sesebelisoa