1.Melemo le bofokoli ba mochine oa welding oa laser le boholo ba oona ba kopo

Mochini oa welding oa laser ke mofuta o mocha oa mokhoa oa ho tjheseletsa, o nang le matla a tlase a bond, sebaka se anngoeng ke mocheso ka bophara le melemo e meng e mengata, 'marakeng oa hona joale oa tšepe, laser welding e' nile ea sebelisoa haholo, esale e sebelisoa mekhoeng eohle ea bophelo. , joalo ka: senoelo sa ho kenya tšepe, indasteri ea liselefouno, indasteri ea bongaka, indasteri ea likoloi le likarolo tse ling tse ngata tsa indasteri.

01 Melemo ea mochini oa welding oa laser

Ha ho bapisoa le theknoloji ea khale ea ho tjheseletsa, theknoloji ea welding ea laser ha e kopane le welding, ts'ebetso ea ts'ebetso ha e hloke khatello, e na le lebelo le potlakileng la welding, matla a phahameng, botebo, deformation e nyane, seam e moqotetsane, sebaka se senyenyane se anngoeng ke mocheso le workpiece. deformation e nyane, mosebetsi oa ts'ebetso o latelang o fokotsehile, o fokotsa tlhahiso ea matsoho, maemo a phahameng, polokeho le melemo e meng.

Theknoloji ea ho tjheseletsa ka laser e ka sebelisoa ho tjheseletsa lisebelisoa tse hanang joalo ka litšepe tse phahameng tse qhibilihang, esita le lisebelisoa tseo e seng tsa tšepe tse kang lirafshoa le likhalase tsa tlhaho, tse nang le litholoana tse ntle tsa welding ho thepa e bōpehileng le ho tenyetseha ho hoholo. Bakeng sa ho tjheseletsa likarolo tse sa fihlelleheng, phetiso e feto-fetohang eo e seng ea puisano e etsoa. Sefate sa laser se ka aroloa ka nako le matla, se nolofalletsa ho sebetsa ka nako e le 'ngoe ha maballo a mangata, ho fana ka maemo a ho tjheseletsa ho nepahetseng haholoanyane.

Lintlha tse 02 tseo u lokelang ho li ela hloko mabapi le ts'ebeliso ea mochini oa welding oa laser

Lintlha tse latelang li lokela ho hlokomeloa ha u sebelisa lisebelisoa tsa mochini oa welding oa laser

(a) Boemo ba karolo e cheselitsoeng e hloka ho nepahala haholo, ho etsa bonnete ba hore e ka har'a sepheo sa lebone la laser.

(b) Ha karolo e cheselitsoeng e hloka ts'ebeliso ea sesebelisoa, ho tlameha ho netefatsoe hore boemo ba ho qetela ba karolo e cheselitsoeng bo hloka ho tsamaellana le sebaka sa weld moo lebone la laser le tla ama teng.

(c) Botenya bo phahameng ka ho fetesisa bo fokotsehile, ho kenella ha li-workpieces tse nang le botenya bo fetang 19mm moleng oa tlhahiso ho hloka ho buisana le moetsi ho fana ka ts'ehetso ea botekgeniki e eketsehileng.

03 Likopo tsa metjhini e tjheseletsang laser

1. Indasteri ea betri

Liselefounu le boholo ba lihlahisoa tsa khoutu ea betri li sebelisoa ka laser welding.

2. Bathroom kitchenware indasteri

Laser welding precision e na le ponahalo e ntle, kahoo ka kamoreng ea ho hlapela ea maemo a holimo, lihlahisoa tsa tšepe tse sa hloekang ka laser ho tšoaea ho na le mefuta e mengata ea likopo. Joalo ka: lihape, lipompo, lithipa tse sehang tse se nang mochini le boholo ba tsela ka ho tšoaea ka laser ea tlhahiso ea LOGO ea likhoebo, liketlele tsa maemo a holimo tsa motlakase le litiiso tse ling le tsona li sebelisa welding ea laser ho phethela. Kitchenware, tableware sehlopha tjheseletsa butt tjheseletsa, bula hlobo hlobo ho etsa le ho lokisa le ho fetola hlobo ha e ntse e sebelisoa.

3. Lihlahisoa tsa digital, liselefouno, indasteri ea lik'homphieutha

Ts'ebetso ea laser ka lebaka la theknoloji e nepahetseng ea ts'ebetso, ho dijithale, mehala ea selefouno, lits'ebetso tsa ts'ebetso ea komporo tse tsebahalang joalo ka: mehala ea selefouno, MP4, MP3 shell laser welding, mohala oa khokahanyo, likhomphutha tsa laptop, lisebelisoa tsa fiber optic spot welding, khomphutha ea chassis sehokelo. .

4. Indasteri ea mechine ea boenjiniere

Ho hloekisa thepa tjheseletsa, electromechanical likarolo tjheseletsa, sehokedi behang tokiso.

5. Elektronike, indasteri ea motlakase

Kaha ts'ebetso ea laser ke mokhoa o sa sebetsaneng le motho, ha o hlahise extrusion ea mechine kapa khatello ea mochine, kahoo e finyella litlhoko tsa ts'ebetso ea indasteri ea elektronike. Tse kang: li-transformer, li-inductors, li-connectors, li-terminals, li-connectors tsa fiber optic, li-sensor, li-switchers, li-switches, li-betri tsa liselefouno, likaroloana tsa microelectronic, li-circuits tse kopantsoeng le lisebelisoa tse ling.

6. Indasteri ea mabenyane

Kaha ts'ebetso ea laser e ntle haholo, e loketse lihlahisoa tsa bohlokoa le tse nyenyane indastering ea mabenyane. Kaha lebone le shebaneng le laser le nepahetse haholo, le holisoa ka microscope ho holisa likarolo tse nyane tsa mabenyane le ho hlokomela welding e nepahetseng. Laser spot welder ke sesebelisoa se hlokahalang bakeng sa ho hokahanya liketane tsa mabenyane le ho kenya majoe a majoe.

7. Lisebelisoa, lisebelisoa, indasteri ea lisebelisoa

Sesebelisoa, sensaro, kitchenware, tableware sehlopha tjheseletsa butt tjheseletsa, bula hlobo hlobo ho etsa le ho lokisa le ho fetola hlobo nakong sebelisoa. Seamless tjheseletsa ea stainless steel tableware, tjheseletsa ka kgokelo ya mitha konokono.

8. Indasteri ea likoloi, likoloi tsa motlakase

Ts'ebetso ea laser bakeng sa ts'ebetso e sa amaneng le batho, ha ho na tšilafalo ea sehlahisoa, lebelo le phahameng, e loketseng haholoanyane litlhoko tsa ts'ebetso ea tlhahiso ea thepa ea bareki e phahameng haholo, joalo ka welding ea koloi, welding ea valve, welding ea piston ring, welding ea koloi ea silinda ea gasket, ho ntša phala, tjheseletsa filthara, tjheseletsa ya likoloi polokeho khase jenereithara. Laser ho khaola likarolo tekong le sethaleng se senyenyane sa tlhahiso ea likoloi tsa likoloi, le ho chesoa ha libeteri bakeng sa likoloi tsa motlakase.

9. Indasteri ea lisebelisoa tsa ho haha mabone a matla

Ts'ebetso ea laser e sebelisoa haholo tlhahisong ea lisele tsa letsatsi tsa laser: joalo ka solar silicon wafer laser scribing cutting, solar water heat heat conduction plate plate welding. Ts'ebetso ea laser, e le mokhoa oa ho boloka tikoloho le o sebetsang hantle, o tla sebelisoa haholo nakong e tlang.

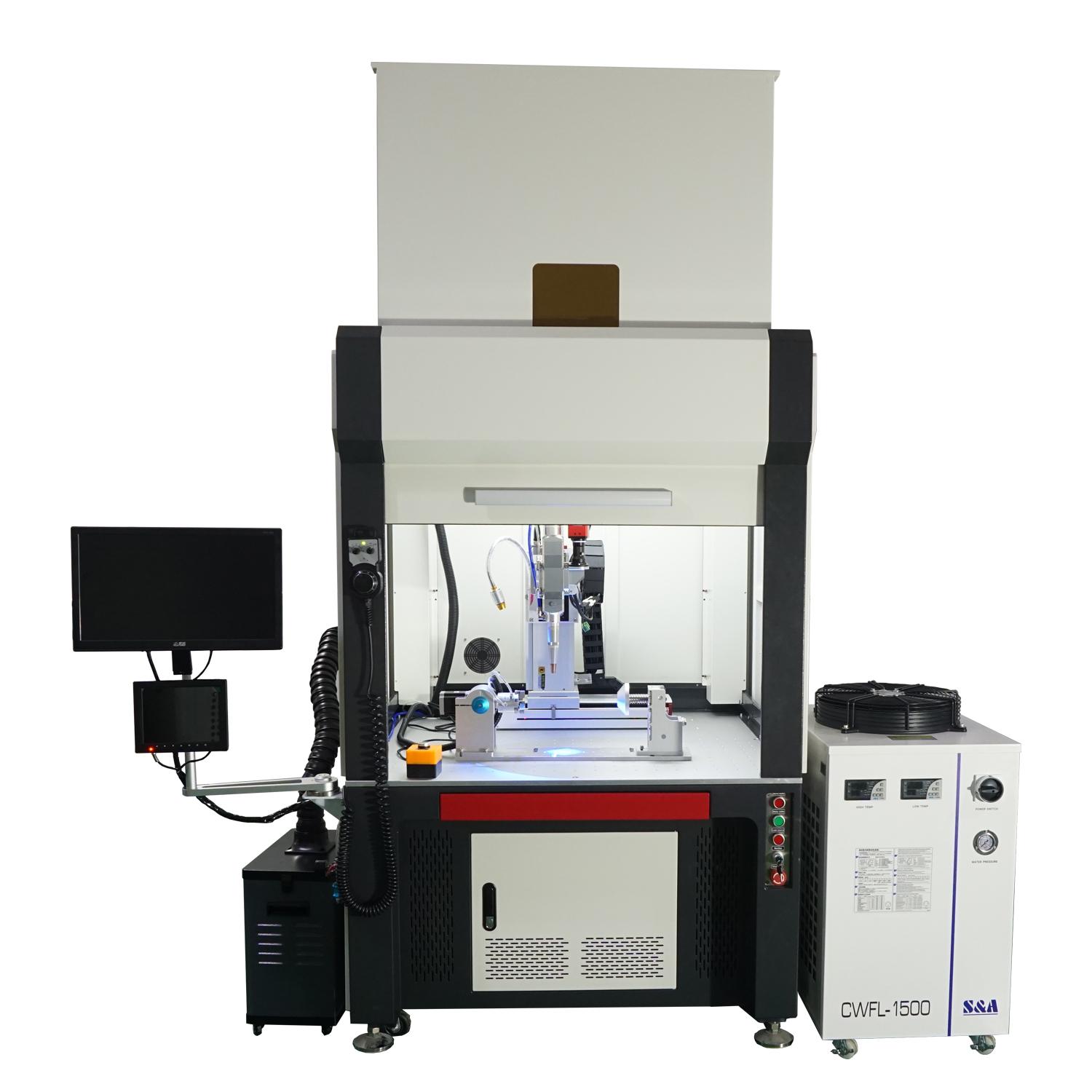

2.Mochini oa welding oa laser oa Platform ke eng?

Platform othomathike laser tjheseletsa mochine ke othomathike tjheseletsa mochine o sebelisang matla a phahameng laser pulses ho futhumatsa thepa sebakeng se senyenyane. Matla a mahlaseli a laser a aroloa ka ho tsamaisa mocheso ho ea ka hare ho thepa 'me thepa e qhibiliha ho etsa letamo le khethehileng le qhibilihisitsoeng. Haholo-holo e sebelisoa bakeng sa ho tjheseletsa ha lisebelisoa tse tšesaane tse nang le marako le likarolo tse nepahetseng, 'me e khona ho hlokomela welding ea motlakase, welding ea butt, welding ea lap, welding ea tiiso, joalo-joalo E na le likarolo tsa bophara ba li-weld tse nyenyane, lebelo la ho tjheseletsa ka potlako, boleng bo phahameng ba ho tjheseletsa, che. porosity, taolo e nepahetseng, ho nepahala ha boemo bo holimo, le boiketsetso bo bonolo.

3.Mochini oa welding oa laser o tšoaroang ka letsoho ke ofe?

Joalo ka ha lebitso le bolela, mochini oa welding oa laser ke mofuta oa lisebelisoa tsa ho tjheseletsa tse hlokang ts'ebetso ea matsoho. Sesebelisoa sena sa tjheseletsa se ka etsa welding ea laser ho li-workpieces tse telele le tse kholo. Ha welding, sebaka se amehileng ke mocheso se nyane mme ha se bake deformation, blackening le matšoao ka morao ho workpiece. Botebo ba ho tjheseletsa bo boholo, ho tjheseletsa ho tiile, ho qhibiliha ho lekane, mme ha ho na ho tepella maikutlong ka letamo la ho qhibiliha moo pono ea thepa e qhibilihisitsoeng e kopanang le substrate.

4.Ho na le phapang efe pakeng tsa mochini o tjheseletsang laser o ikatisang le mochini o ts'oarellang oa laser o tšoaroang ka letsoho?

Automatic laser tjheseletsa metjhini ka tsela e iketsang tjheseletsa ho ea ka lenaneo sete ka mor'a ho thehoa ka software; mechine laser tjheseletsa manual, e tsejoang hape e le letheba tjheseletsa, sebelisoa ke basebelisi ha ba sebelisa thepa laser tjheseletsa ka magnification phahameng ho skrine.

Visual spot welding e etsoa ka letsoho 'me hangata e etsoa ke baetsi ba lisebelisoa tsa laser ho fihlela litlhoko tsa mosebelisi. Ke bahlahisi ba fokolang ba nang le thepa ea thepa. Haeba lintho tsa stock li fumaneha, li fuoa mosebelisi e le mohlala kapa sesupo sa bopaki. Habohlokoa le ho feta, matla le likarolo tsa thepa ea ho cheseletsa li khethoa ka ho buisana le mosebedisi, hape re lokela ho fa mosebedisi sehlahisoa sa thepa e bolokang chelete e ngata ho latela theko ea theko. Boemong bofe, ho molemo ho sebelisa mochini oa welding oa laser, ha o bapisoa le mochini oa welding oa laser o ikemetseng, eseng feela litšenyehelo tsa theko e phahameng, empa litšenyehelo tsa tlhokomelo le tsona li phahame haholo. Ntho e nepahetseng haholoanyane ke ea bohlokoa haholo bakeng sa tlhokomelo 'me ka tlhaho e phahamisa litšenyehelo. Ntle le moo, welding ea laser ka botlalo e tsepamisa maikutlo ho CNC automation ea sethala sa mosebetsi, se hlokang ts'ebetso e phahameng le ho feto-fetoha ha sethala sa mosebetsi, empa ka ts'ebetso, sena ha se panacea, 'me lihlahisoa tse ngata tse fapaneng li ke ke tsa sebelisoa. e fokotsa karolo ea mochini oa welding oa laser oa othomathike. Kajeno, re tsepamisitse maikutlo ho mochini oa welding oa laser, kahoo sesebelisoa sa tataiso ka tlhaho se rarolla mathata a kaholimo. Mosebetsi oa eona oa ho tjheseletsa ke ho etsa ts'ebetso ea ho tjheseletsa ka letsoho la laser tjheseletsa lenonyeletso le nang le li-angles tse fapaneng tsa taolo, kahoo ho ka boleloa hore ke lisebelisoa tse sa tloaelehang tsa laser ho ikamahanya le tjheseletso ea libopeho tse ngata le li-angles tsa lihlahisoa. Hafeela matla a ntse a phahame ka ho lekaneng, a ka ikamahanya le welding ea lihlahisoa tse ngata

Ka sebele tlhahiso ea mechine e tjheseletsang laser e tlase haholo ho feta ya disebediswa tse itirisang ka botlalo. Leha ho le joalo, bakeng sa ts'ebetso e arolelanoang kapa ts'ebetso e seng e kholo le ho tjheseletsa ha limela tsa tlhahiso, ho tjheseletsa laser ho molemo ho feta. Ha ho hlokahale ho lokisa tafole ea welding le ho qoba bothata ba sebaka se seholo sa fatše. Ho phaella moo, lithupelo tse nyenyane li hlahisa lihlahisoa tse fapa-fapaneng tse nang le libopeho tse sa tloaelehang, kahoo mochine oa laser oa manual o ka finyella litlhoko tsa tlhahiso e joalo 'me o na le mokhoa o motle oa ho ikamahanya le maemo.

Manual laser welding ntle le tafole e nepahetseng ea welding, tšebeliso e tlase ea lisebelisoa le litšenyehelo tse tlase tsa tlhokomelo ea lisebelisoa. Ka kakaretso, re hloka ho boloka libenche tse ngata tsa mosebetsi, athe lisebelisoa tsa laser tsa letsoho li ka phethela ts'ebetso ha feela li na le manonyeletso a nkehang a laser welding. Ho bonolo ho nkela sebaka, theko e tlase ea likarolo tse ncha. Haeba u sa tsebe ho li nkela sebaka, u ka li fa moetsi bakeng sa tlhokomelo e tobileng ntle le ho tšoenyeha ka ho tsamaisa thepa.

Phapang pakeng tsa mechine ea ho tjheseletsa ea laser e ikemetseng le mechine ea welding ea laser e arolelanoa mona. Batho ba bangata ba ka 'na ba nahana hore mochine oa laser o itekanetseng o molemo hobane o iketsetsa, empa' nete ke hore mefuta e 'meli ea lisebelisoa e sebelisetsoa merero e fapaneng' me e 'ngoe le e' ngoe e na le melemo ea eona. Ts'ebetsong ea khetho, re boetse re hloka ho khetha lisebelisoa tse nepahetseng tsa laser welding bakeng sa tlhahiso ea rona ho latela litlhoko tsa rona tsa nnete.

Nako ea poso: Feb-01-2023