Lilemong tsa morao tjena, tlhoekiso ea laser e fetohile e 'ngoe ea libaka tsa lipatlisiso lefapheng la tlhahiso ea indasteri, lipatlisiso li akaretsa ts'ebetso, khopolo, lisebelisoa le lits'ebetso. Lisebelisoa tsa indasteri, theknoloji ea ho hloekisa ka laser e khonne ho hloekisa ka botšepehi palo e kholo ea libaka tse fapaneng tsa substrate, lintho tse hloekisang tse kenyeletsang tšepe, aluminium, titanium, khalase le lisebelisoa tse kopantsoeng, joalo-joalo, liindasteri tsa kopo tse koahelang sefofane, lifofane, likepe, lebelo le phahameng. seporo, likoloi, hlobo, matla a nyutlelie le libaka tsa leoatle le tse ling.

Theknoloji ea ho hloekisa laser, e qalileng lilemong tsa bo-1960, e na le melemo ea phello e ntle ea ho hloekisa, mefuta e mengata ea likopo, ho nepahala ho phahameng, ho se kopane le ho fumaneha. Ka tlhahiso ea indasteri, tlhahiso le tlhokomelo le likarolo tse ling li na le menyetla e mengata ea kopo, ho lebeletsoe hore ka mokhoa o sa fellang kapa ka ho feletseng o nkele mekhoa e tloaelehileng ea ho hloekisa, 'me e be theknoloji e tšepisang ka ho fetisisa ea ho hloekisa botala lekholong la bo21 la lilemo.

Mokhoa oa ho hloekisa laser

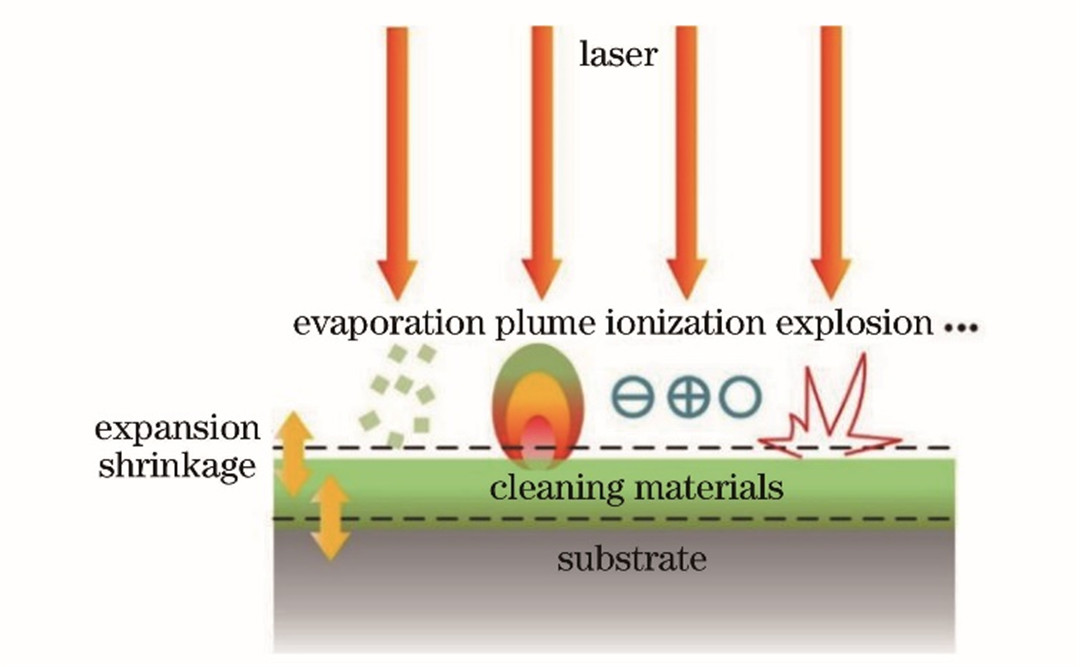

Ts'ebetso ea ho hloekisa laser e rarahane haholo, e kenyelletsang mekhoa e fapaneng ea ho tlosa thepa, bakeng sa mokhoa oa ho hloekisa laser, mokhoa oa ho hloekisa o ka ba teng ka nako e le 'ngoe mekhoa e fapaneng ea mekhoa, e hlahisoang haholo ke tšebelisano pakeng tsa laser le thepa, ho kenyelletsa Thepa holim'a ablation, decomposition, ionization, degradation, melting, combustion, vaporization, vibration, sputtering, katoloso, shrinkage, ho phatloha, peeling, tšolloa le liphetoho tse ling 'meleng le lik'hemik'hale. tshebetso.

Hajoale, mekhoa e tloahelehileng ea ho hloekisa ka laser haholo-holo e meraro: ho hloekisa ka laser ablation, ho hloekisoa ka laser filimi-assisted laser le mekhoa ea laser shock wave.

Mokhoa oa ho hloekisa ka laser

Mekhoa e ka sehloohong ea mekhoa ea mekhoa ke ho atolosa mocheso, mouoane, ablation le ho phatloha ha karolo. Laser e sebetsa ka kotloloho ho thepa e lokelang ho ntšoa ka holim'a substrate mme maemo a tikoloho e ka ba moea, khase e fumanehang seoelo kapa vacuum. Maemo a ts'ebetso a bonolo ebile a sebelisoa ka ho fetisisa ho tlosa mefuta e sa tšoaneng ea ho roala, lipente, likaroloana kapa litšila. Setšoantšo se ka tlase se bontša setšoantšo sa ts'ebetso ea mokhoa oa ho hloekisa ka laser ablation.

Ha mahlaseli a laser holim'a thepa, substrate le lisebelisoa tsa ho hloekisa ke katoloso ea pele ea mocheso. Ka keketseho ea nako ea tšebelisano ea laser le thepa ea ho hloekisa, haeba mocheso o le tlase ho feta monyako oa cavitation ea thepa ea ho hloekisa, lisebelisoa tsa ho hloekisa ke ts'ebetso ea phetoho ea 'mele feela, phapang lipakeng tsa thepa ea ho hloekisa le coefficient ea katoloso ea mocheso ea substrate e lebisa khatellong ea sebopeho. , thepa ea ho hloekisa e phunyeletsoa, ho taboha ho tloha holim'a substrate, ho phunyeha, ho robeha ha mechine, ho senya ho sisinyeha, joalo-joalo, thepa ea ho hloekisa e tlosoa ka jete kapa e tlosoa holim'a substrate.

Haeba mocheso o phahame ho feta mocheso oa mocheso oa mocheso oa mocheso oa thepa ea ho hloekisa, ho tla ba le maemo a mabeli: 1) moeli oa ablation oa thepa ea ho hloekisa o ka tlaase ho substrate; 2) monyako oa ablation oa thepa ea ho hloekisa o moholo ho feta substrate.

Liketsahalo tsena tse peli tsa lisebelisoa tsa ho hloekisa li qhibiliha, cavitation le ablation le liphetoho tse ling tsa physicochemical, mochine oa ho hloekisa o rarahane haholoanyane, ho phaella liphellong tsa mocheso, empa hape o ka kenyelletsa lisebelisoa tsa ho hloekisa le li-substrates pakeng tsa ho senyeha ha limolek'hule, ho senyeha ha thepa kapa ho senyeha, mohato. ho phatloha, lisebelisoa tsa ho hloekisa gasification hang-hang ionization, tlhahiso ea plasma.

(1)Filimi ea metsi e thusa ho hloekisa ka laser

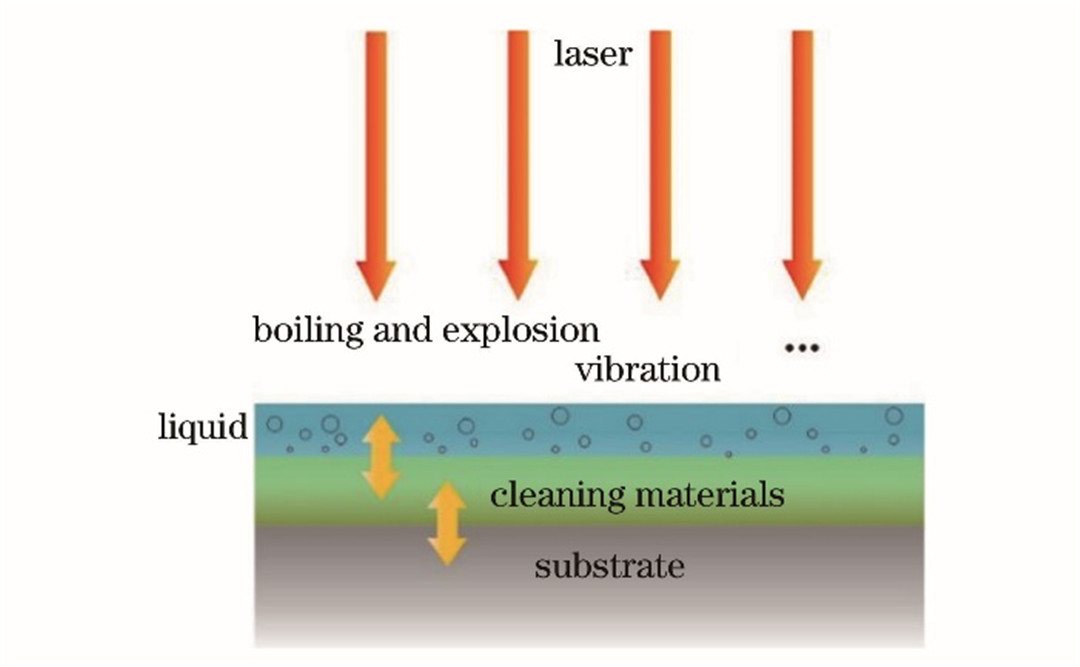

Mokhoa mochine haholo-holo o na le mokelikeli filimi a phehile vaporization le vibration, joalo-joalo. Tšebeliso ea tlhokahalo ea ho khetha laser wavelength e loketseng, ka mokhoa oa ho etsa hore ho be le khaello ea khatello ea ts'ebetso ea ho hloekisa laser, e ka sebelisoa ho tlosa. tse ling tse thata ho tlosa ntho ea ho hloekisa.

Joalokaha ho bontšitsoe setšoantšong se ka tlase, filimi ea metsi (metsi, ethanol kapa lino tse ling) e koahetsoe pele ka holim'a ntho e hloekisang, ebe e sebelisa laser ho e khantša. Filimi ea metsi e monya matla a laser a bakang ho phatloha ho matla ha mecha ea litaba ea mokelikeli, ho phatloha ha mokelikeli o belang ka lebelo le phahameng, ho fetisoa ha matla holim'a lisebelisoa tsa ho hloekisa, matla a phahameng a nakoana a phatlohileng a lekane ho tlosa litšila tse holim'a metsi ho finyella merero ea ho hloekisa.

Mokhoa oa ho hloekisa laser o thusang filimi ea metsi o na le mefokolo e 'meli.

Ts'ebetso e thata ebile e thata ho laola ts'ebetso.

Ka lebaka la tšebeliso ea filimi ea metsi, lik'hemik'hale tsa motsoako oa substrate ka mor'a ho hloekisa ho bonolo ho fetoha le ho hlahisa lintho tse ncha.

(1)Mokhoa oa ho hloekisa mofuta oa laser shock wave

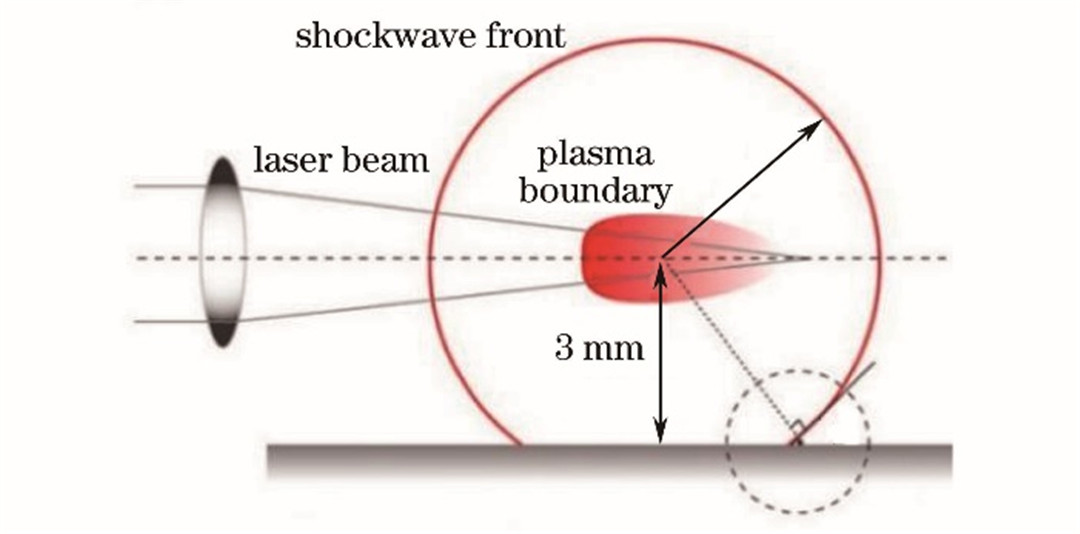

Mokhoa oa ts'ebetso le mochine o fapane haholo le tse peli tsa pele, mochine ke haholo-holo ho tlosoa ha matla a ts'oaetso, ho hloekisa lintho ke likaroloana, haholo-holo bakeng sa ho tlosoa ha likaroloana (sub-micron kapa nanoscale). Litlhoko tsa ts'ebetso li thata haholo, ka bobeli ho etsa bonnete ba hore bokhoni ba ho ionize moea, empa hape le ho boloka sebaka se loketseng pakeng tsa laser le substrate ho netefatsa hore ketso ea likaroloana tsa matla a tšusumetso e kholo ka ho lekaneng.

Sets'oants'o sa ts'ebetso ea laser shock wave schematic se bonts'itsoe ka tlase, laser ho tsamaisana le tataiso ea sebaka sa substrate, 'me substrate ha e kopane. Tsamaisa sesebediswa kapa hlooho ea laser ho lokisa tsepamiso ea laser ho karolo e haufi le phallo ea laser, sebaka se shebaneng le ts'ebetso ea ionization ea moea e tla etsahala, e leng se tla baka maqhubu a ts'oenyehileng, maqhubu a ts'oenyehileng ho atolosoeng ka potlako ha spherical katoloso, 'me e atolosetsoe ho ikopanya. ka likaroloana. Ha nako ea karolo e fapaneng ea leqhubu la ts'oaetso holim'a karoloana e kholo ho feta nako ea karolo ea longitudinal le matla a ho khomarela likaroloana, karoloana e tla tlosoa ka ho roala.

Theknoloji ea ho hloekisa laser

Laser hloekisa mochine e haholo-holo e thehiloeng holim'a ntho ka mor'a ho monya matla laser, kapa vaporization le volatilization, kapa hang-hang katoloso ea mocheso ho hlōla adsorption ea likaroloana holim'a metsi, e le hore ntho e tsoang holimo, 'me joale finyella sepheo sa ho hloekisa.

Ka bokhutšoaane e ka ba: 1. laser vapor decomposition, 2. laser stripping, 3. thermal atoloso ea likaroloana tsa litšila, 4. substrate surface vibration le particle vibration lintlha tse nne

Ha ho bapisoa le mokhoa o tloaelehileng oa ho hloekisa, theknoloji ea laser ea ho hloekisa e na le litšobotsi tse latelang.

1. Ke ho hloekisa "o omileng", ha ho na tharollo ea ho hloekisa kapa lisebelisoa tse ling tsa lik'hemik'hale, 'me bohloeki bo phahame haholo ho feta mokhoa oa ho hloekisa lik'hemik'hale.

2. Sebaka sa ho tlosoa ha litšila le sebaka se sebetsang sa substrate se pharaletseng haholo, 'me

3. Ka taolo ea mekhoa ea laser process parameters, e ke ke ea senya bokaholimo ba substrate motheong oa ho tlosoa ka katleho ha litšila, ke bokaholimo bo botle joaloka bo bocha.

4. Ho hloekisa ka laser ho ka sebetsa habonolo.

5. Thepa ea decontamination ea laser e ka sebelisoa nako e telele, litšenyehelo tse tlaase tsa ts'ebetso.

6. Theknoloji ea ho hloekisa laser ke: botala: mokhoa oa ho hloekisa, ho felisa litšila ke phofo e tiileng, boholo bo nyane, bo bonolo ho bo boloka, ha e le hantle bo ke ke ba silafatsa tikoloho.

Lilemong tsa bo-1980, tsoelo-pele e potlakileng ea indasteri ea semiconductor holim'a likaroloana tsa tšilafalo tsa silicon wafer mask ea theknoloji ea ho hloekisa e ile ea beha litlhoko tse phahameng, ntlha ea bohlokoa ke ho hlōla tšilafalo ea likaroloana tse nyenyane le karoloana pakeng tsa matla a maholo a adsorption. , ho hloekisa lik'hemik'hale tse tloaelehileng, ho hloekisa mechine, mekhoa ea ho hloekisa ka ultrasonic ha e khone ho finyella tlhokahalo, 'me ho hloekisa laser ho ka rarolla mathata a joalo a tšilafalo, lipatlisiso tse amanang le likopo li 'nile tsa ntlafatsoa ka potlako.

Ka 1987, ponahalo ea pele ea kopo ea patent ho hloekisa laser. Lilemong tsa bo-1990, Zapka e atlehile ho sebelisa thekenoloji ea ho hloekisa ka laser ho mokhoa oa ho etsa semiconductor ho tlosa likaroloana tse nyenyane holim'a mask, ho lemoha ts'ebeliso ea pele ea theknoloji ea ho hloekisa laser lefapheng la indasteri. Ka 1995, bafuputsi ba ile ba sebelisa laser ea 2 kW TEA-CO2 ho finyella katleho ea ho hloekisa ho tlosoa ha pente ea fuselage ea lifofane.

Ka mor'a ho kena lekholong la bo21 la lilemo, ka tsoelo-pele e phahameng ea li-lasers tsa ultra-short pulse, lipatlisiso tsa malapeng le tsa linaheng tse ling le ts'ebeliso ea theknoloji ea ho hloekisa ka laser e ile ea eketseha butle-butle, ho lebisa tlhokomelo holim'a thepa ea tšepe, likopo tse tloaelehileng tsa linaheng tse ling ke ho tlosoa ha pente ea fuselage, hlobo. holim'a metsi, ho tlosoa ha carbon ka hare ho enjene le ho hloekisa holim'a manonyeletso pele ho tjheseletsa. US Edison Welding Institute laser ho hloekisa sefofane sa ntoa sa FG16, ha matla a laser a 1 kW, molumo oa ho hloekisa oa 2.36 cm3 ka motsotso.

Ho bohlokoa ho bolela hore lipatlisiso le ts'ebeliso ea ho tlosa pente ea laser ea likarolo tse tsoetseng pele tsa motsoako le eona ke sebaka se seholo se chesang. Sesole sa US Navy HG53, HG56 helicopter propeller blades le F16 fighter jete mohatla le libaka tse ling tse kopantsoeng li se li lemohuoe lits'ebetso tsa ho tlosa pente ea laser, ha lisebelisoa tsa China tse entsoeng ka sefofane li se li le morao, kahoo lipatlisiso tse joalo li se li le sekheo.

Ntle le moo, ts'ebeliso ea mahlale a ho hloekisa ka laser ho kalafo ea bokaholimo ba CFRP pele ho gluing ho ntlafatsa matla a lenonyeletso le eona ke e 'ngoe ea tse tsepamisoang maikutlo hajoale. ikamahanya le khamphani ea laser ho mohala oa tlhahiso ea koloi ea Audi TT ho fana ka lisebelisoa tsa ho hloekisa ka laser fiber ho hloekisa bokaholimo ba filimi e bobebe ea aluminium alloy door frame oxide. Rolls G Royce UK e sebelisitse ho hloekisa ka laser ho hloekisa filimi ea oxide holim'a likarolo tsa enjine ea titanium aero-engine.

Theknoloji ea ho hloekisa ka laser e tsoetse pele ka potlako lilemong tse peli tse fetileng, ebang ke mekhoa ea ho hloekisa ka laser le mochine oa ho hloekisa, lipatlisiso tsa ho hloekisa ntho kapa tšebeliso ea lipatlisiso li entse tsoelo-pele e kholo. Theknoloji ea ho hloekisa ka laser ka mor'a lipatlisiso tse ngata tsa theory, sepheo sa lipatlisiso tsa eona se lula se leeme mabapi le ts'ebeliso ea lipatlisiso, le ts'ebelisong ea liphetho tse ts'episang. Nakong e tlang, thekenoloji ea ho hloekisa ka laser ho sireletsa li-relics tsa setso le mesebetsi ea bonono e tla sebelisoa haholo, 'me maraka a eona a pharaletseng haholo. Ka ntshetsopele ya mahlale le thekenoloji, tshebediso ya thekenoloji ya ho hlwekisa ka laser indastering e fetoha nnete, mme sebaka sa ts'ebeliso se ntse se ata haholo.

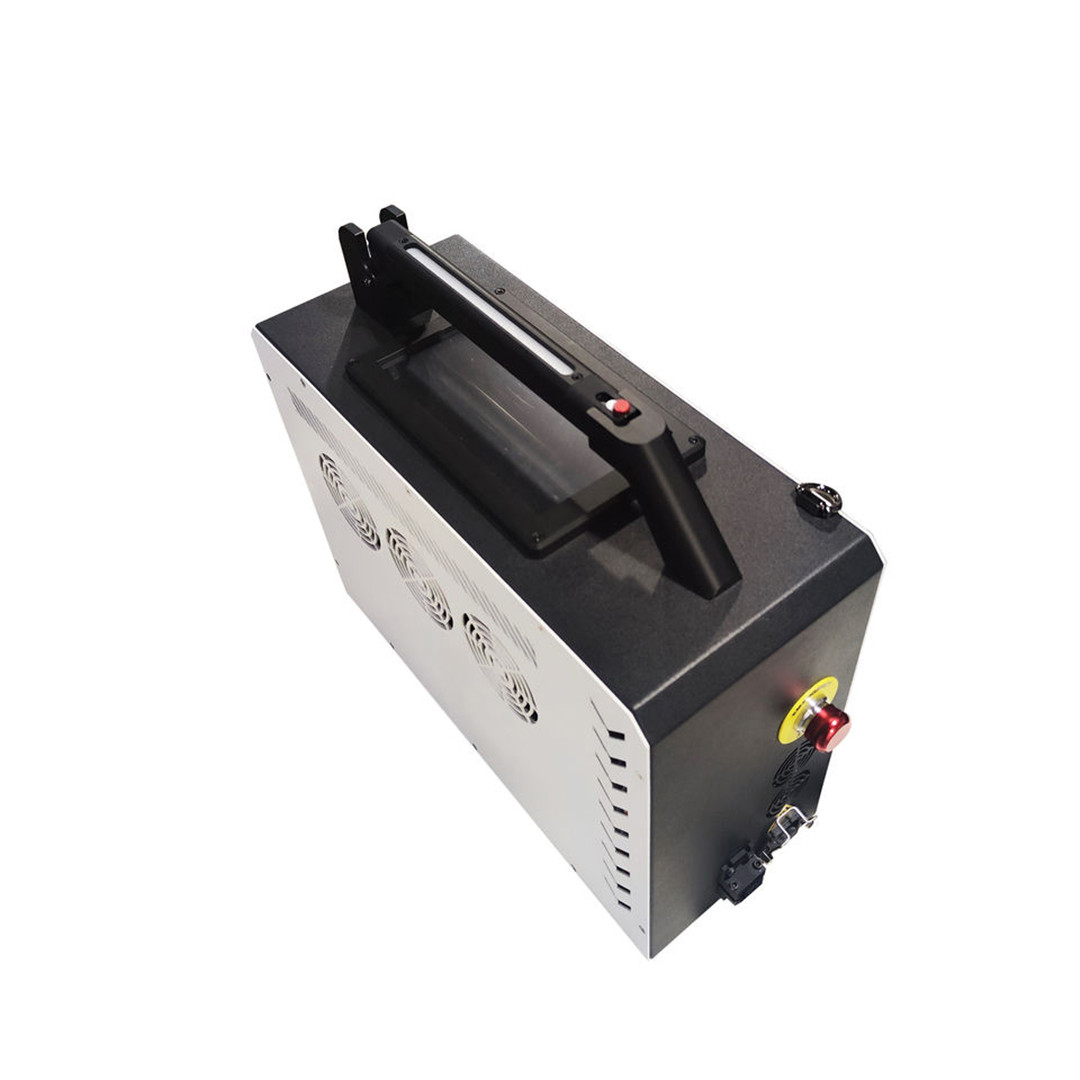

Maven laser automation company e tsepamisitse maikutlo indastering ea laser ka lilemo tse 14, re sebetsa ka mokhoa o ikhethileng oa ho tšoaea laser, re na le mochini oa khabinete ea ho hloekisa ka laser, mochini oa trolley case laser o hloekisang, mochini o hloekisang laser le tse tharo mochining o le mong oa ho hloekisa laser, ho feta moo, re na le mochini oa tjheseletsa oa laser, mochini oa ho itšeha oa laser le mochini oa ho betla oa laser, haeba o thahasella mochini oa rona, o ka re latela mme o ikutloe o lokolohile ho ikopanya le rona.

Nako ea poso: Nov-14-2022