Mechini ea welding ea liroboto ka laserba fetotse indasteri ea li-welding ka ho nepahala, ho tenyetseha le ho sebetsa hantle.

Mechini ena e kopanya matla ali-laser tsa fiberka ho feto-fetoha ha matsoho a liroboto bakeng sa lits'ebetso tse fapaneng ho pholletsa le liindasteri tse fapaneng.

Maven robotic laser welder ke mohlala o ka sehloohong oa theknoloji ena e tsoetseng pele, e fanang ka bokhoni bo ke keng ba lekanngoa le ho tenyetseha ha maemo.

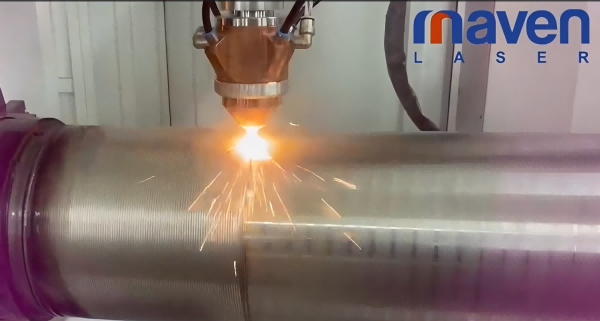

Mochini oa ho tjheseletsa oa laser oa Maven o na le lebone le nang le matla a phahameng a faeba e kopantsoeng hantle le letsoho la robotiki ea li-axis tse tšeletseng.

Motsoako ona o thusa ho laola le ho sisinyeha ka nepo, ho lumella mochini hore o khone ho tsamaisa tsela efe kapa efe sebakeng. Ho feto-fetoha ha maemo ho ke ke ha bapisoa le mechine ea li-welding ea setso, ho etsa hore Maven robotic laser welder e be letlotlo la bohlokoa bakeng sa bahlahisi ba sebetsanang le litlhoko tse rarahaneng tsa welding.

O mong oa melemo ea mantlha ea Maven robotic laser welder ke bokhoni ba eona ba ho cheselletsa likarolo tseo ka tloaelo li-welders tsa setso li ke keng tsa li tjheseletsa.

Matsoho a liroboto a hlophiselitsoe ho kena libakeng tse thata le lijeometri tse rarahaneng, ho netefatsa hore le likarolo tse rarahaneng ka ho fetisisa li ka chesetsoa ka nepo. Tšobotsi ena e fana ka bahlahisi ba nang le maemo a phahameng ka ho fetisisa ha ba ntse ba khona ho sebetsana ka sebete le mefuta e sa tšoaneng ea li-welding ka mochine o le mong.

Ho feta moo, theMaven robotic laser weldere na le bokhoni bo ikhethang ba ho arola lebone la laser ka nako le matla.

Mokhoa ona o mocha o lumella maballo a mangata hore a sebetsoe ka nako e le 'ngoe, a eketsa haholo tlhahiso ea li-welding.

Ka ho sebelisa matla a maballo a laser a mangata, mochini o ka phethela mesebetsi ea welding ka mokhoa o atlehileng haholoanyane, o hlahisang tlhahiso e phahameng le linako tse khutšoane tsa tlhahiso.

Tšobotsi ena ke ea bohlokoa haholo bakeng sa ts'ebetso ea tlhahiso e phahameng moo ho leng bohlokoa haholo ho potlakisa le ho sebetsa hantle.

Mochini oa welding oa laser oa Mavene na le mefuta e mengata ea likopo le tšusumetso e kholo. Indastering ea likoloi, mochini o sebelisetsoa ho cheselletsa likarolo tse rarahaneng tsa 'mele ea likoloi, litsamaiso tsa ho tima le li-powertrain ka nepo e ke keng ea bapisoa.

Bokhoni ba eona ba ho fihla libakeng tseo ho leng thata ho fihla ho tsona bo etsa hore e be tharollo e loketseng bakeng sa ho tjheseletsa likarolo tse rarahaneng tsa likoloi, ho thusa ho ntlafatsa boleng ba kakaretso le ho tšoarella ha sehlahisoa sa ho qetela.

Indastering ea sefofane, Maven robotic laser welders e sebelisoa ho cheselletsa likarolo tsa bohlokoa tsa meaho ea lifofane, lienjineri le sistimi ea propulsion.

Ho nepahala ha mochini le ho feto-fetoha ha maemo ho etsa hore o tšoanelehe hantle bakeng sa litlhoko tse boima tsa tlhahiso ea sebaka sa sefofane, moo botšepehi ba ho cheselletsa bo bohlokoa bakeng sa polokeho le ts'ebetso.

Ntle le moo, mochini o boetse o sebelisoa indastering ea lisebelisoa tsa bongaka mme o ka sebelisoa ho cheselletsa likarolo tse rarahaneng le tse nepahetseng lisebelisoa tsa bongaka le li-implants. Bokhoni ba eona ba ho sebetsana le li-geometri tse rarahaneng le ho mamellana ka thata ho etsa hore e be sesebelisoa sa bohlokoa bakeng sa bahlahisi tšimong, ho netefatsa tlhahiso ea lisebelisoa tsa bongaka tsa boleng bo phahameng tse finyellang litekanyetso tse thata tsa taolo.

Maven robotic laser welders le tsona li sebelisoa indastering ea elektroniki ho tjheseletsa likarolo tse nyane, tse rarahaneng tsa lisebelisoa tsa elektroniki le lipotoloho.

Ho nepahala ha eona le bokhoni ba ho sebetsana le lintlha tse ntle ho etsa hore e be tharollo e loketseng bakeng sa ho kopanya likarolo tsa elektronike tse nepahetseng, ho thusa ho ntlafatsa ts'epo le ts'ebetso ea lihlahisoa tsa elektroniki.

Ka bokhutšoanyane, Maven robotic laser welder e emela tsoelo-pele e kholo ea theknoloji ea welding, e fanang ka maemo a fetohang a ke keng a bapisoa, ho nepahala le tlhahiso.

Bokhoni ba eona ba ho cheselletsa sebaka leha e le sefe sepakapakeng, ho fihlella libaka tseo ho leng thata ho fihla ho tsona, le ho sebetsana le maballo a laser a mangata ka nako e le 'ngoe ho etsa hore e be letlotlo le fapaneng le la bohlokoa ho baetsi ba liindasteri tse fapaneng. Ka mefuta e mengata ea lits'ebetso le likarolo tse ncha, mochini oa welding oa laser oa Maven robotic o lebelletsoe ho tsoela pele ho ntšetsa pele tsoelo-pele ea theknoloji ea welding le ho fihlela litlhoko tse lulang li fetoha tsa tlhahiso ea sejoale-joale.

Nako ea poso: Aug-22-2024