Ka Pherekhong 2023, lik'hamphani tse 'maloa tsa Machaena li phatlalalitse merero ea katoloso ea libeteri tsa matla le polokelo ea matla, ka chelete ea matsete e atamelang li-yuan tse limilione tse likete tse 100 le matla a kopaneng a tlhahiso ea 269 GWh, e fetang tlhahiso e kopaneng halofong ea pele ea selemo se fetileng (206.4 GWh). ) 'me e batla e fana ka tlhokahalo ea betri ea motlakase ea lapeng e kentsoeng selemong se fetileng (294.6 GWh)

| Khoebo | Chelete ea matsete (Bilione) | Matla a tlhahiso(GWh) |

| BYD | 10 (E hakantsoeng) | 35 |

| Eva KHABANE | 20.8 | 80 |

| Lithium ea Ganfeng | 15 | 34 |

| BAK KHABANE | 13 | 30 |

| Farasis Energy | 10 | 30 |

| Sehlopha sa Shenghong | 30.6 | 60 |

| Kakaretso | 99.4 | 269 |

Mohloli oa lintlha: Litaba tsa Likoloi tsa China, data ea sechaba ea marang-rang

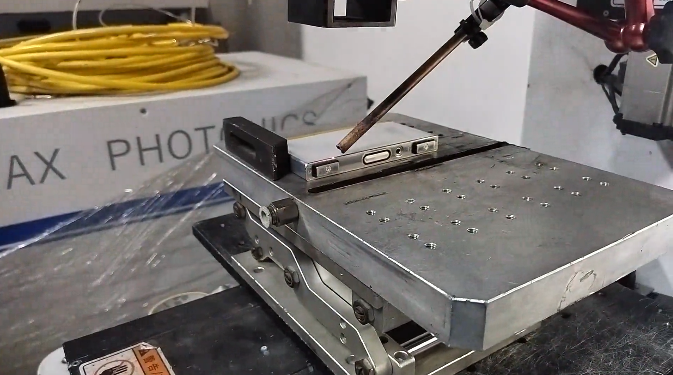

Nakong ea tlhahiso ea libeteri tsa matla, botsitso ba boleng ba khetla ea betri bo tla ama botsitso le polokeho ea sistimi ea kopano ea betri. Bohareng ba khetla ea betri ea matla haholo-holo e na le electrolyte ea tlhaho, diaphragm e khethehileng, 'me sekoahelo se na le valve e thibelang ho phatloha, poso ea palo, sekoahelo sa tšireletso, lesoba la ente ea mokelikeli, joalo-joalo. 'me boleng ba eona ba ho tjheseletsa bo ama ka ho toba tekanyo ea ho tiisa ea betri,' me ho tjheseletsa ho fokolang ho tla lebisa ho lutla ha betri, pula ea lithium, 'me ponahalo ea betri ha e finyelle maemo.

▲Sekoahelo se thata sa lisekoere tsa lithium betri

01 Mathata a tloaelehileng a seam seam

1- Ponahalo e mpe: leeme la ho cheselletsa, mahlo a lehlabathe, mohlala oa ho sekamela

2- Matla a sa lekaneng le ho tiisa: botebo bo sa lekaneng ba fusion, mapetsong, masoba a maholo a moea a bakang ho lutla ha betri.

02 Tlhahlobo ea ts'ebetso ea mathata a seam ea welding

Ho latela tlhahlobo ea phoso ea FTA, bothata ba ho hloleha ha tjheseletsa bo akaretsoa haholo e le chebahalo e mpe le mathata a matla a tjheseletsa. Lintho tse mpe tsa ponahalo: lisebelisoa tsa ho tjheseletsa CCD tsoelo-pele ea ho hlahloba, mofuta oa khase e sireletsang le sekhahla sa phallo, bohloeki ba sampole ea welding, ho nepahala le mokhoa oa ho sebetsa. Matla a ho tjheseletsa le mabaka a ho tiisa: thepa e tala ka nepo, sebopeho sa aluminium, phello ea mekhahlelo ea ts'ebetso.

| Karolelano | Lipotso | Ho arola Sesosa sa Ts'ebetso | Mabaka a tobileng |

|

Ponahalo | Welding e sa fellang | Tsela ea ho cheselletsa Ho tsebahatsa le ho beha maemo | Ts'ebetso ea ho beha pono ea CCD ha e khone ho khetholla ka mokhoa o nepahetseng likarolo tsa mohlala, e leng se etsang hore ho be le litsela tse khelohileng tsa welding, tlhahiso e sa lekaneng ea mohloli oa leseli o thusang ho sampuli, le bothata bo eketsehileng ba ho beha lifoto. |

| Sekoti sa moea sa trachoma | Thepa ka boeona le tikoloho tjheseletsa | Sebopeho sa thepa ea khetla ea aluminium, mokhoa o sa lokelang oa mofuta oa khase e sireletsang le sekhahla sa phallo, ho bapisa ho sa nepahalang ha mokhoa o ka holimo oa tjheseletsa le lekhalo la weld ea sekoahelo le khetla, bohloeki bo sa lekaneng ba ho tjheseletsa ka lehlakore kapa sebaka se holimo sa welding. | |

| Ho se leka-lekane ha mohlala | Ho nepahala ha kopano ea sampole | Koahela le khetla top tjheseletsa mokhoa weld lekhalo lumellane ka tsela e sa nepahalang, tjheseletsa tshebetso khatello ea kelello bokella. | |

| Matla a ho tjheseletsa | Ho tsoa ha betri | Phoso ea boholo ba mohlala le tšusumetso ea li-parameter tsa welding | Sekoahelo le khetla ho lekana boholo ha bo tsitsitse, 'me litekanyetso tsa ts'ebetso ha lia behoa ka nepo. |

03 Karolo ea khase e sireletsang

Khase e sireletsang ts'ebetsong ea welding ea laser e ka thibela oxidation ea bokaholimo ba tšepe, ea sireletsa lense, ea tima plasma, ea hloka ho laola tsela ea phallo ea moea, khatello, sekhahla sa phallo. Khase e sireletsang e etsa moferefere, weld e tla ba le porosity, seam weld seam le mathata a mang.

04 Litšobotsi tse fapaneng tsa khase

Mefuta ea likhase tse sireletsang bakeng sa welding ea laser e kenyelletsa helium, argon le nitrogen

Helium: tekanyo e phahameng ea ionization, laser e ka feta, matla ohle a marang-rang a fihla holim'a mosebetsi, ha ho bonolo ho hlahisa porosity, empa e theko e boima.

Argon: theko e tlase ho feta helium, empa e ka hlaseloa ke mocheso o phahameng oa ionization ea plasma, leha ts'ireletso e le betere, empa e tla sireletsa karolo ea ts'ebetso ea matla a laser, e fokotsa matla a laser, ts'ebeliso ea helium welding e shebahala e boreleli.

Naetrojene: theko e tlase, ionization e nyane, ho ruruha ha welding ho tla arabela ka likarolo tse ling tsa alloy ea aluminium ho hlahisa metsoako e sa tsitsang, e amang matla a tjheseletsa.

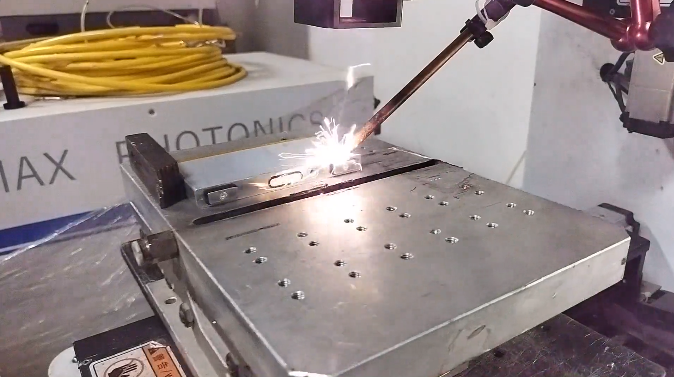

05 Tlhahlobo ea phello ea maemo a fapaneng a tjheseletsa

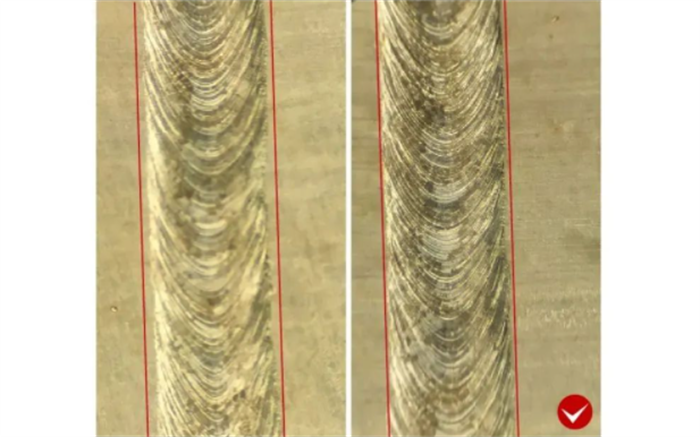

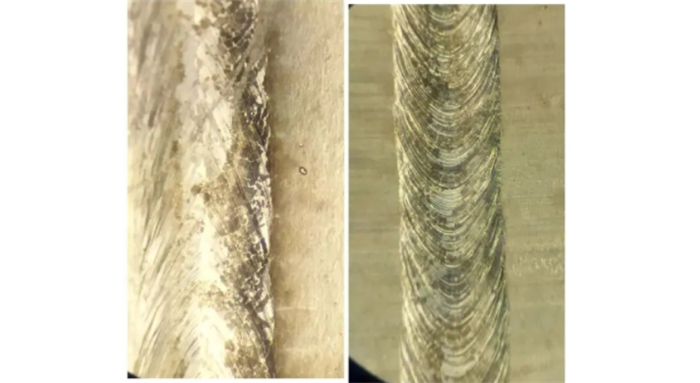

Welding ka naetrojene le argon e le khase e sireletsang, ha u sebelisa naetrojene e le khase e sireletsang, bophara ba weld boa fokola, ho sebelisoa argon e le khase e sireletsang, ho buloa ha weld ho boreleli, mohlala oa sekala sa tlhapi o ntlafalitsoe ka mokhoa o ts'oanang, 'me ponahalo e ntle ho feta ho sebelisa. lihlahisoa tsa nitrogen welding. (Joalokaha ho bontšitsoe setšoantšong se ka tlase)

▲ Phello e fapaneng ea ts'ireletso ea khase (sebopeho se fapaneng sa bophara ba seam)

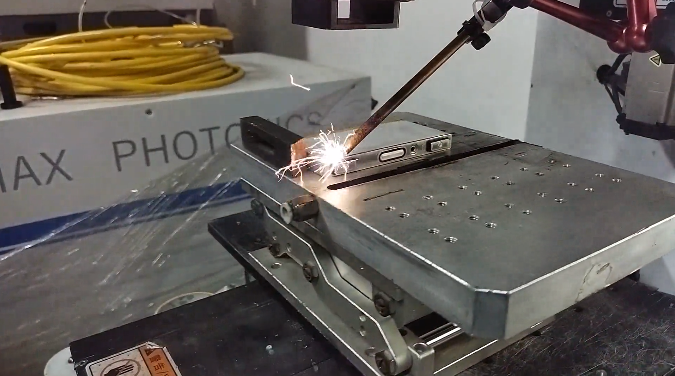

Laser matla ka tšusumetso ea tjheseletsa, ho sebelisa lebelo le tšoanang tjheseletsa le khase e sireletsang, ho phahama ha matla a sebele, ka potlako thepa ea weld e ka qhibiliha 'me ea fetoha mouoane, metsi a qhibilihang a letamo a eketseha, sebopeho sa tlhapi sa tlhapi se tšoana le ho feta, seam weld se bataletse ho feta. (Joalokaha ho bontšitsoe setšoantšong se ka tlase)

▲ Phello e fapaneng ea ho tjheseletsa matla (ho fapana ha bokaholimo bo fapaneng)

Kakaretso

1. ho setsi sa ho qetela lisebelisoa tsa ho tiisa ka laser, boemo ba CCD scanning le li-parameter tsa welding li na le tšusumetso ho ponahalo ea bobe bothateng ba ho tjheseletsa ka mokhoa o sa fellang.

2. Mefuta e sireletsang ea khase le litlhophiso tsa parameter li ka ntlafatsa ts'ebetso ea junifomo ea weld, ho netefatsa bohloeki ba sebaka sa welding, ho fokotsa ho kenngoa ha litšila tse tsoang linaheng tse ling, ho ka fokotsa slag ea welding e hlahisoang ke trachoma porosity.

3. Mechanical loketseng ka lekhalo ho loketse ho molemo ho feta tšitiso loketseng, tšimo tjheseletsa tshebetso pele letheba tjheseletsa 'me joale tsoelang pele tjheseletsa tsela, ka haholo rarolla lekhalo loketseng ha mathata tjheseletsa botsitso.

Maven Laser ke k'hamphani e shebaneng le indasteri ea laser, e thehiloeng ka 2008, hona joale e na le lilemo tse 5 tsa boiphihlelo lefapheng la welding ea laser, e ikhethang ka ho khetha litharollo tse loketseng ka ho fetisisa tsa welding le metjhini e tšoanang ea welding bakeng sa hau. Ka Pherekhong, re ile ra qala mochini oa rona oa morao-rao oa laser air-cooled handheld handheld, o seng o le nakong e khethehileng ea papatso, reka li-unit tse 5, theko ea unit e le 'ngoe e tlase ho $4500, reka li-unit tse 10, theko ea unit e le' ngoe. chelete e ka tlase ho $4200. Moea o pholileng ka letsoho o monyenyane, o loketse ho cheselletsa ka ntle, 'me mochine oa ho tjheseletsa oa laser oa Maven oa moea o pholileng o rarolla bothata ba hona joale ba mocheso oa mochine 'me o ka sebetsa nako e telele ntle le tšitiso. Rea u amohela potsong ea hau! Re Maven Laser, molekane oa hau oa setsebi oa laser.

Nako ea poso: Mar-03-2023