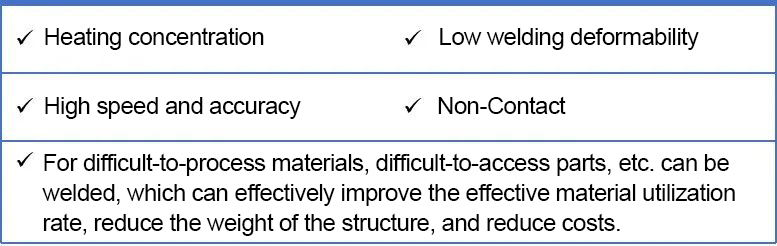

Theknoloji ea ho kopanya ka laser, kapa theknoloji ea welding ea laser, e sebelisa lebone le phahameng la laser ho tsepamisa maikutlo le ho laola mahlaseli a holim'a thepa, 'me bokaholimo ba thepa bo monya matla a laser ebe bo o fetola matla a mocheso, ho etsa hore thepa e futhumale le ho qhibiliha sebakeng seo. , e lateloa ke ho pholisa le ho tiisa ho finyella ho kopanngoa ha thepa ea homogeneous kapa e sa tšoaneng. Ts'ebetso ea welding ea laser e hloka matla a matla a laser a 104ho ea ho 108W/cm2. Ha ho bapisoa le mekhoa ea khale ea welding, laser welding e na le melemo e latelang.

Theknoloji ea ho kopanya ka laser, kapa theknoloji ea welding ea laser, e sebelisa lebone le phahameng la laser ho tsepamisa maikutlo le ho laola mahlaseli a holim'a thepa, 'me bokaholimo ba thepa bo monya matla a laser ebe bo o fetola matla a mocheso, ho etsa hore thepa e futhumale le ho qhibiliha sebakeng seo. , e lateloa ke ho pholisa le ho tiisa ho finyella ho kopanngoa ha thepa ea homogeneous kapa e sa tšoaneng. Ts'ebetso ea welding ea laser e hloka matla a matla a laser a 104ho ea ho 108W/cm2. Ha ho bapisoa le mekhoa ea khale ea welding, laser welding e na le melemo e latelang.

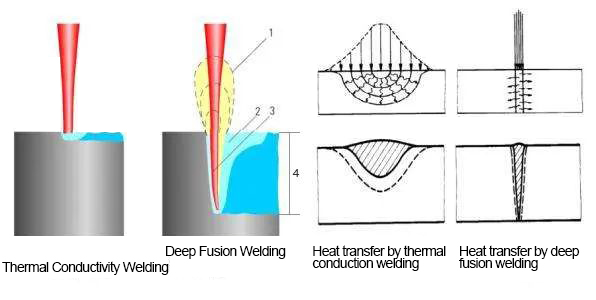

1-plasma cloud, 2-melting material, 3-keyhole, 4-botebo ba fusion

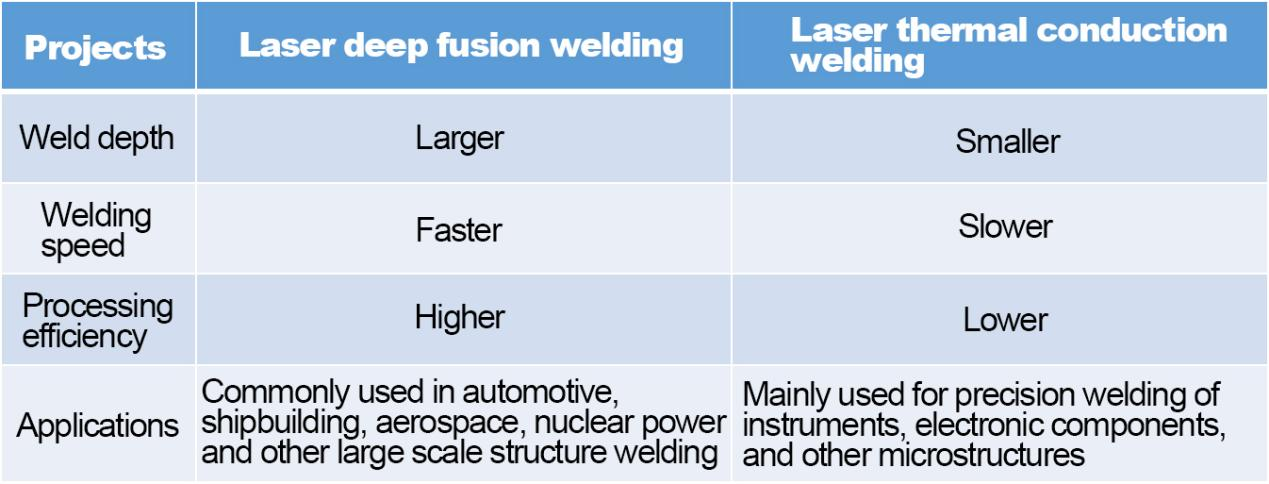

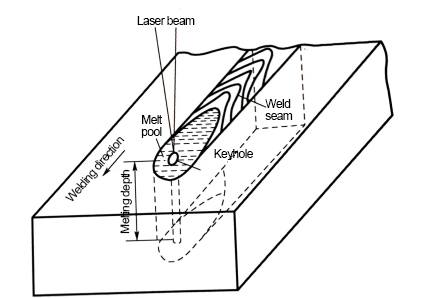

Ka lebaka la ho ba teng ha keyhole, laser beam, ka mor'a ho irradiating ka hare ho keyhole, e tla eketsa ho monya ha laser ka thepa le ho khothalletsa ho thehoa ha letamo le qhibilihisitsoeng ka mor'a ho hasana le liphello tse ling, mekhoa e 'meli ea tjheseletsa e bapisoa. ka mokoa o latelang.

Palo e kaholimo e fana ka ts'ebetso ea welding ea laser ea thepa e tšoanang le mohloli o tšoanang oa leseli, mochini oa ho fetola matla o etsoa feela ka lesoba la senotlolo, senotlolo le tšepe e qhibilihisitsoeng haufi le lerako la lesoba le tsamaeang le pele ha lebone la laser, tšepe e qhibilihisitsoeng e suthisetsa lesoba la senotlolo hole le moea o siiloeng ka morao hore o tlale, 'me ka mor'a ho qhibidiha, ho etsa seam weld.

Haeba thepa e lokelang ho chesetsoa ke tšepe e sa tšoaneng, ho ba teng ha liphapang tsa thepa ea mocheso ho tla ba le tšusumetso e kholo ts'ebetsong ea ho cheselletsa, joalo ka ho se tšoane ha lintlha tse qhibilihisang, conductivity ea mocheso, matla a khethehileng a mocheso, le li-coefficients tsa katoloso ea thepa e sa tšoaneng, ka tjheseletsa khatello ea kelello, tjheseletsa deformation, 'me liphetoho ka maemo a crystallization a tshepe lenonyeletso welded, etsa hore ho fokotseha ha thepa ea mechine ea tjheseletsa.

Ka hona, ho latela litšoaneleho tse fapaneng tsa sebaka sa welding, ts'ebetso ea welding e hlahisitse welding ea laser filler, laser brazing, dual-beam laser welding, laser composite welding, jj.

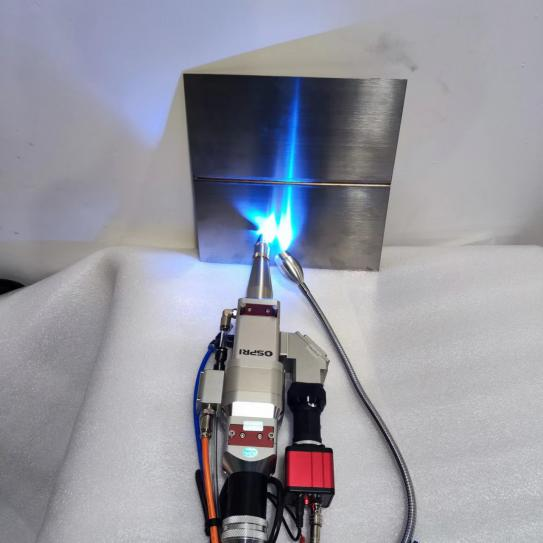

Laser Wire Tlatsa Welding

Ts'ebetsong ea laser welding ea aluminium, titanium le lialloys tsa koporo, ka lebaka la ho monya ho tlase ha leseli la laser (<10%) lisebelisoa tsena, plasma ea foto e na le tšireletso e itseng ea lebone la laser, kahoo ho bonolo ho theha spatter le ho lebisa molokong oa mefokolo joalo ka porosity le mapetsong. Ho phaella moo, boleng ba tjheseletsa bo boetse bo ameha ha lekhalo pakeng tsa li-workpieces le leholo ho feta bophara ba letheba nakong ea sputtering e tšesaane ea poleiti.

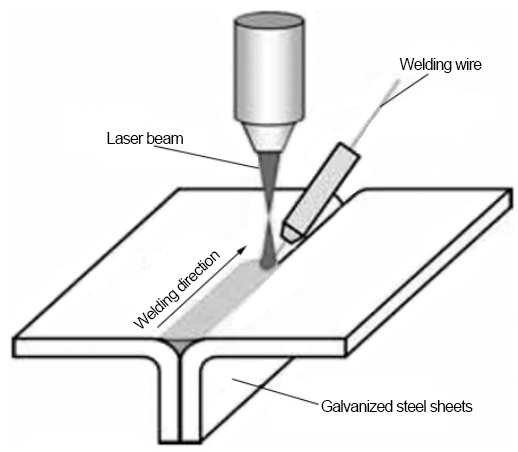

Ho rarolla mathata a ka holimo, sephetho se betere sa welding se ka fumanoa ka ho sebelisa mokhoa oa ho tlatsa. Filler e ka ba terata kapa phofo, kapa ho ka sebelisoa mokhoa o hlophisitsoeng esale pele. Ka lebaka la sebaka se senyenyane se tsepamisitsoeng, weld e ba moqotetsane 'me e na le sebopeho sa convex hanyenyane ka holim'a metsi ka mor'a hore ho sebelisoe thepa ea ho tlatsa.

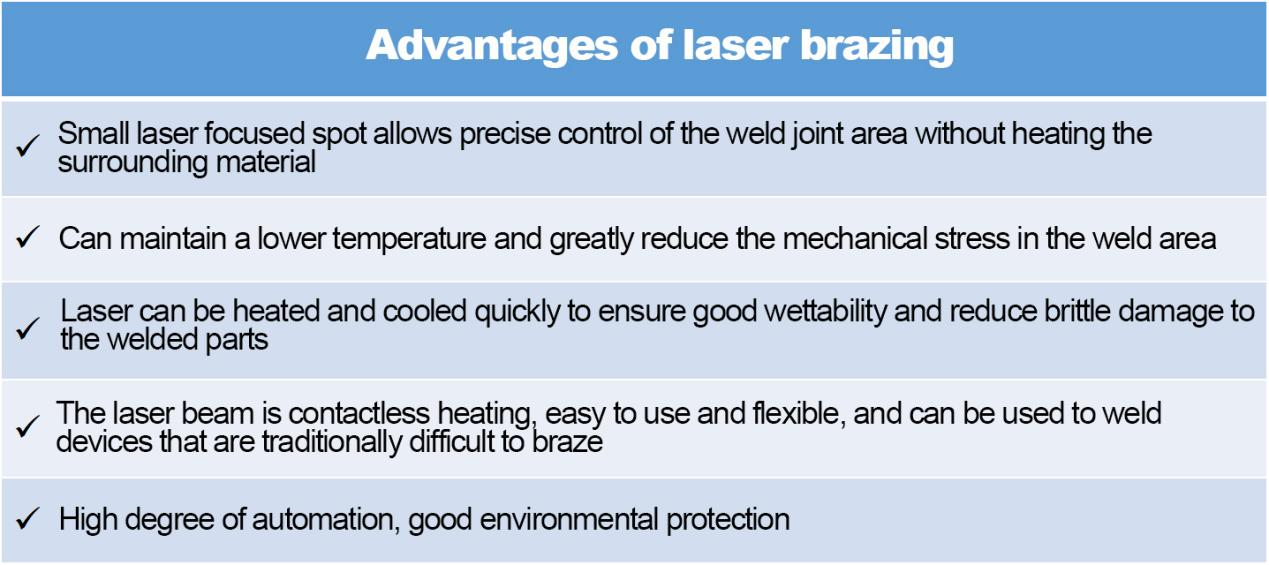

Khabiso ea laser

Ho fapana le fusion welding, e qhibilihisang likarolo tse peli tse cheselitsoeng ka nako e le 'ngoe, brazing e eketsa thepa ea ho tlatsa e nang le ntlha e tlase ea ho qhibiliha ho feta thepa ea motheo ho ea holim'a weld, e qhibilihisa thepa ea ho tlatsa ho tlatsa lekhalo ka mocheso o tlase ho feta ho qhibiliha ha thepa ea motheo. ntlha 'me e phahame ho feta ntlha ea ho qhibiliha ha thepa ea ho tlatsa, ebe e kopana ho etsa weld e tiileng.

Brazing e loketse lisebelisoa tsa microelectronic tse sa utloisiseng mocheso, lipoleiti tse tšesaane le lisebelisoa tsa tšepe tse sa tsitsang.

Ho feta moo, e ka aroloa ka ho eketsehileng e le brazing e bonolo (<450 ° C) le brazing e thata (> 450 ° C) ho itšetlehile ka mocheso oo thepa ea brazing e futhumatsoang ka eona.

Ho tjheseletsa Laser ka Dual Beam

Dual-beam welding e lumella taolo e bonolo le e bonolo ea nako ea mahlaseli a laser le boemo, kahoo e lokisa kabo ea matla.

E sebelisoa haholo-holo bakeng sa welding ea laser ea aluminium le magnesium alloys, splice le lap plate welding bakeng sa likoloi, laser brazing le deep fusion welding.

Beam e habeli e ka fumanoa ka li-lasers tse peli tse ikemetseng kapa ka ho petsoha ha mapolanka ka sekhahla sa borokho.

Mabala a mabeli a ka ba motsoako oa li-lasers tse nang le litšobotsi tse fapaneng tsa nako (pulsed vs. continuous), li-wavelengths tse fapaneng (mid-infrared vs. Wavelengths tse bonahalang) le matla a fapaneng, a ka khethoang ho ea ka thepa ea sebele e sebetsitsoeng.

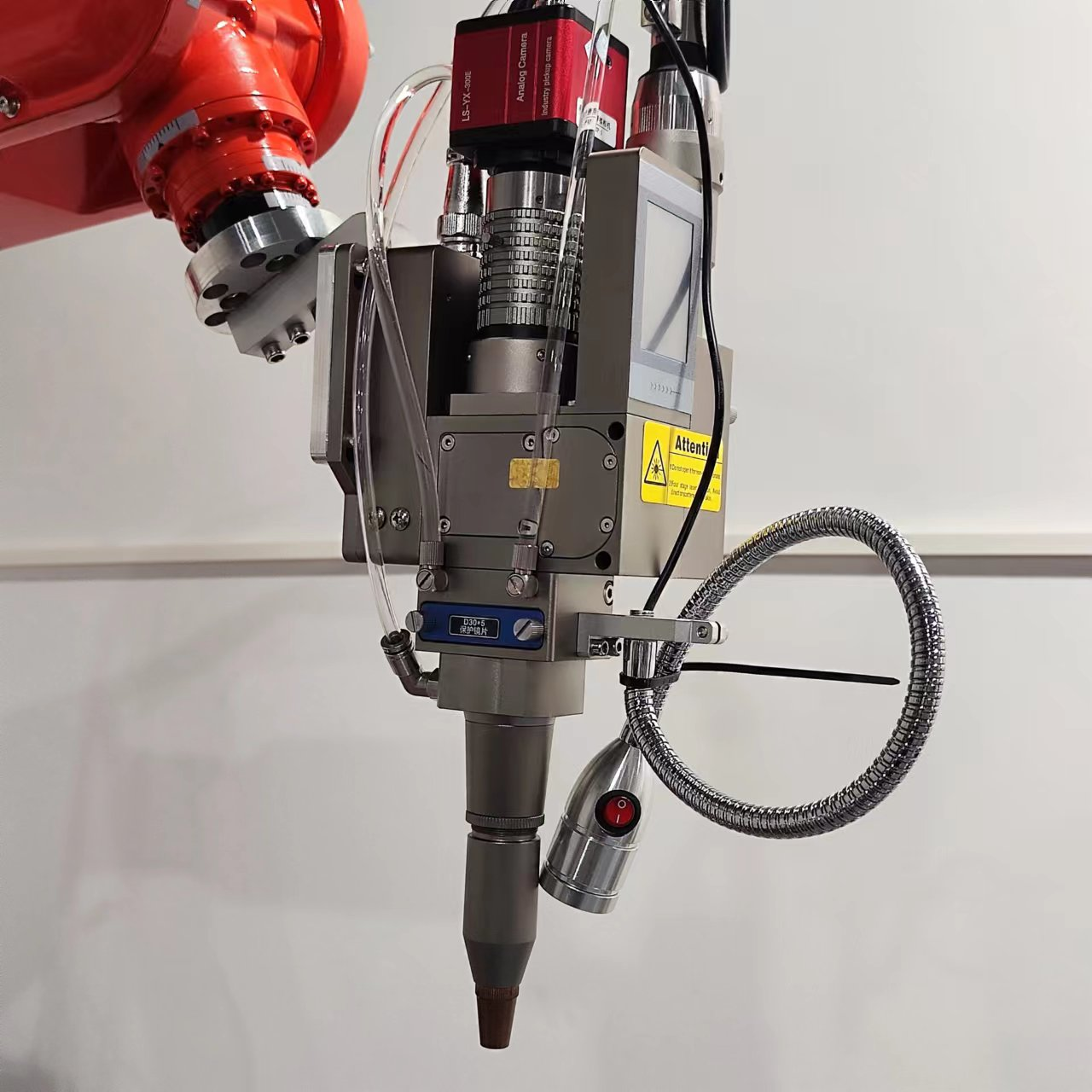

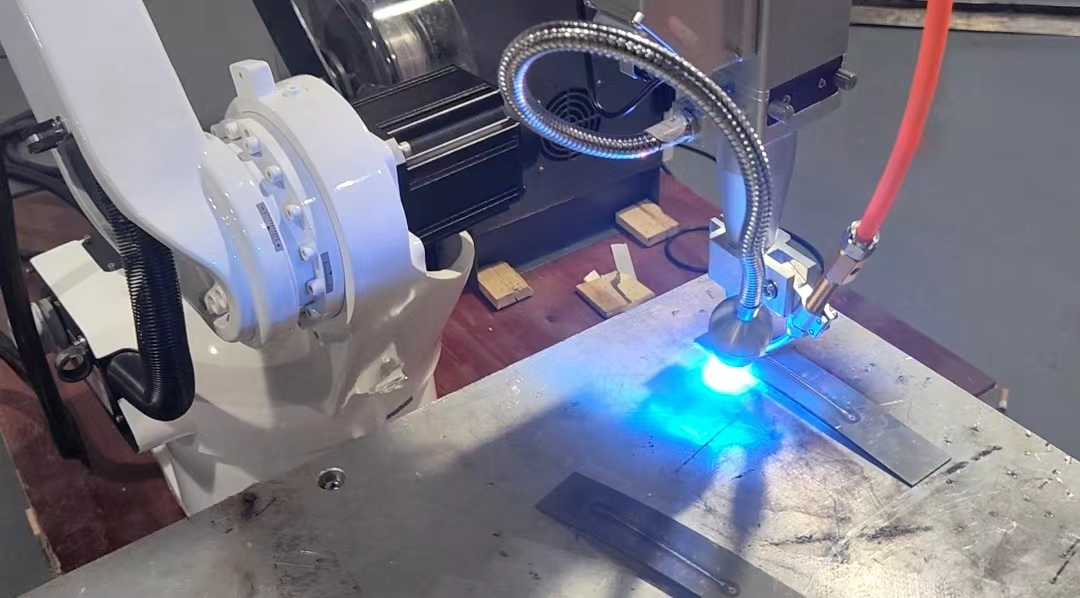

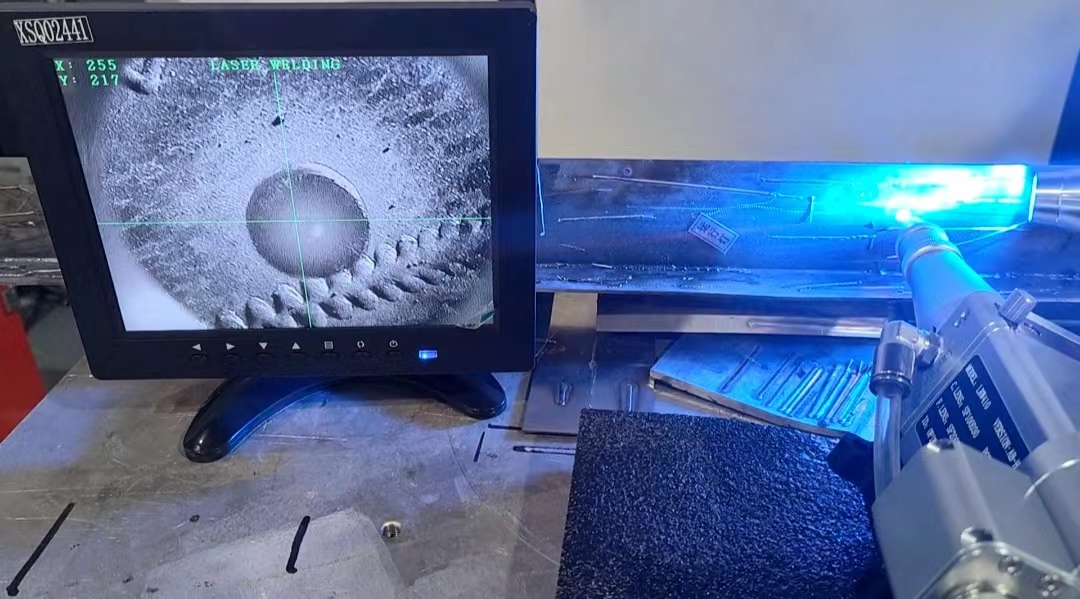

4.Laser Composite Welding

Ka lebaka la ts'ebeliso ea lebone la laser e le mohloli o le mong oa mocheso, mocheso o le mong oa laser welding o na le sekhahla se tlase sa phetolo ea matla le sekhahla sa ts'ebeliso, sehokelo sa boema-kepe sa weld se bonolo ho hlahisa ho se lumellane, ho bonolo ho hlahisa li-pores le mapetsong le mefokolo e meng, ho rarolla bothata bona, o ka sebelisa litšobotsi tse futhumatsang tsa mehloli e meng ea mocheso ho ntlafatsa ho futhumatsa ha laser holim'a workpiece, hangata e bitsoang laser composite welding.

Mofuta o ka sehloohong oa laser composite welding ke motsoako oa laser le arc ea motlakase, 1 + 1> 2 phello e tjena.

ka mor'a lebone la laser haufi le arc e sebelisitsoeng,segokanyipalo sa elektrone e fokotsehile haholo, Leru la plasma le hlahisoang ke laser welding le hlapolotsoe, e lenge ka etsa hore sekhahla sa ho monya ha laser se ntlafatse haholo, ha arc holim'a thepa ea motheo ea preheating e tla eketsa lebelo la ho monya ha laser.

2. tšebeliso e phahameng ea matla ea arc le kakaretsotšebeliso ea matla e tla eketseha.

3, sebaka sa ts'ebetso sa laser welding se nyane, ho bonolo ho baka ho se tsamaisane hantle ha kou ea welding, ha ts'ebetso ea mocheso oa arc e le kholo, e ka khonangfokotsa ho se tsamaisane hantle ha boema-kepe ba tjheseletsa. Ka nako e tšoanang, theboleng ba welding le katleho ea arc e ntlafalitsoeka lebaka la ho tsepamisa maikutlo le ho tataisa ha lebone la laser holim'a arc.

4, laser welding e nang le mocheso o phahameng o phahameng, sebaka se seholo se anngoeng ke mocheso, ho pholisa ka potlako le lebelo la ho tiisa, ho bonolo ho hlahisa mapetsong le li-pores; ha sebaka sa arc se amehileng ke mocheso se le senyane, se ka fokotsang mocheso oa mocheso, ho pholisa, lebelo la ho tiisa,e ka fokotsa le ho felisa moloko oa li-pores le mapetsong.

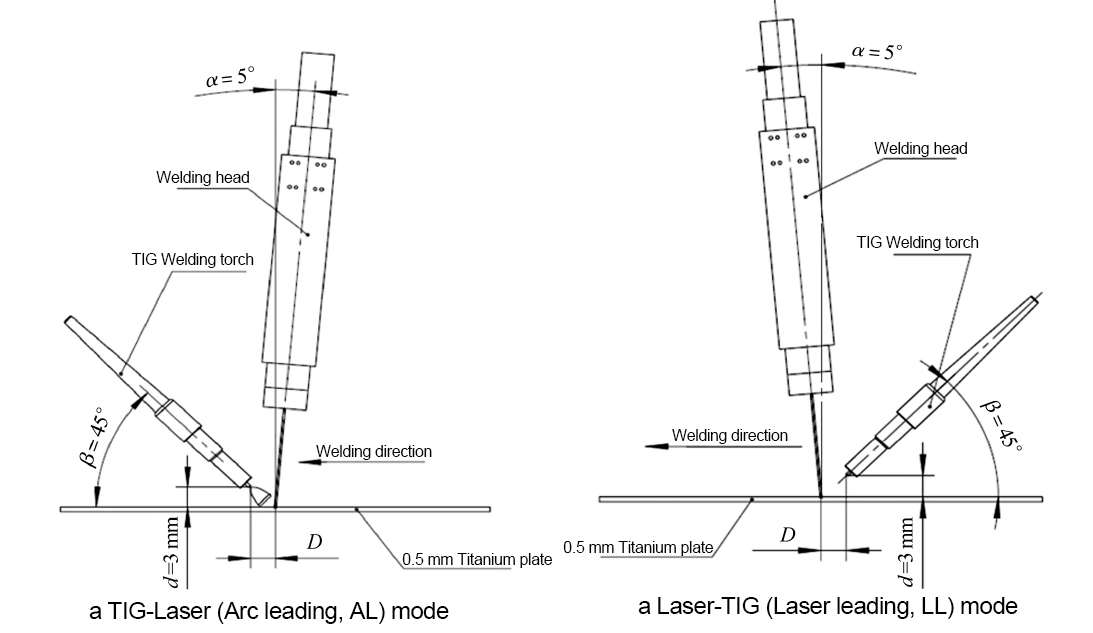

Ho na le mefuta e 'meli e tloaelehileng ea laser-arc composite welding: laser-TIG composite welding (joalokaha ho bontšitsoe ka tlase) le laser-MIG composite welding.

Ho boetse ho na le mefuta e meng ea tjheseletsa e kang laser le plasma arc, laser le inductive heat source compound welding.

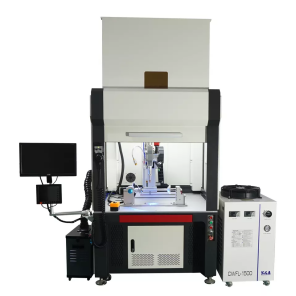

Mabapi le MavenLaser

Maven Laser ke moetapele oa ts'ebeliso ea laser indastering ea China le mofani ea nang le matla oa tharollo ea lefats'e ea laser. Re utloisisa ka botebo mokhoa oa nts'etsopele ea indasteri ea tlhahiso, re lula re ruisa lihlahisoa tsa rona le tharollo, re tsitlallela ho hlahloba ho kopanngoa ha li-automation, informationization le bohlale le indasteri ea tlhahiso, ho fana ka lisebelisoa tsa laser welding, lisebelisoa tsa ho tšoaea laser, lisebelisoa tsa ho hloekisa laser le mabenyane a laser le silevera. lisebelisoa tsa ho itšeha bakeng sa liindasteri tse fapa-fapaneng ho kenyelletsa letoto le felletseng la matla, le ho atolosa ts'usumetso ea rona tšimong ea lisebelisoa tsa laser.

Nako ea poso: Jan-13-2023