Ntho ea bohlokoa ea ho hloekisa ka laser ke matla a phahameng a matla a mahlaseli a mahlaseli a laser holim'a sebaka sa mosebetsi, e le hore bokaholimo ba sebaka sa mosebetsi se be litšila, oxidation, plating kapa ho roala, joalo-joalo ka mocheso oa ho qhibiliha hang-hang, ablation, mouoane. kapa ho hlobolisa, e le ho finyella sebaka se hloekileng sa mosebetsi ntle le ho senya ts'ebetso ea substrate, ke khetho e nepahetseng bakeng sa moloko o mocha oa theknoloji ea ho hloekisa indasteri.

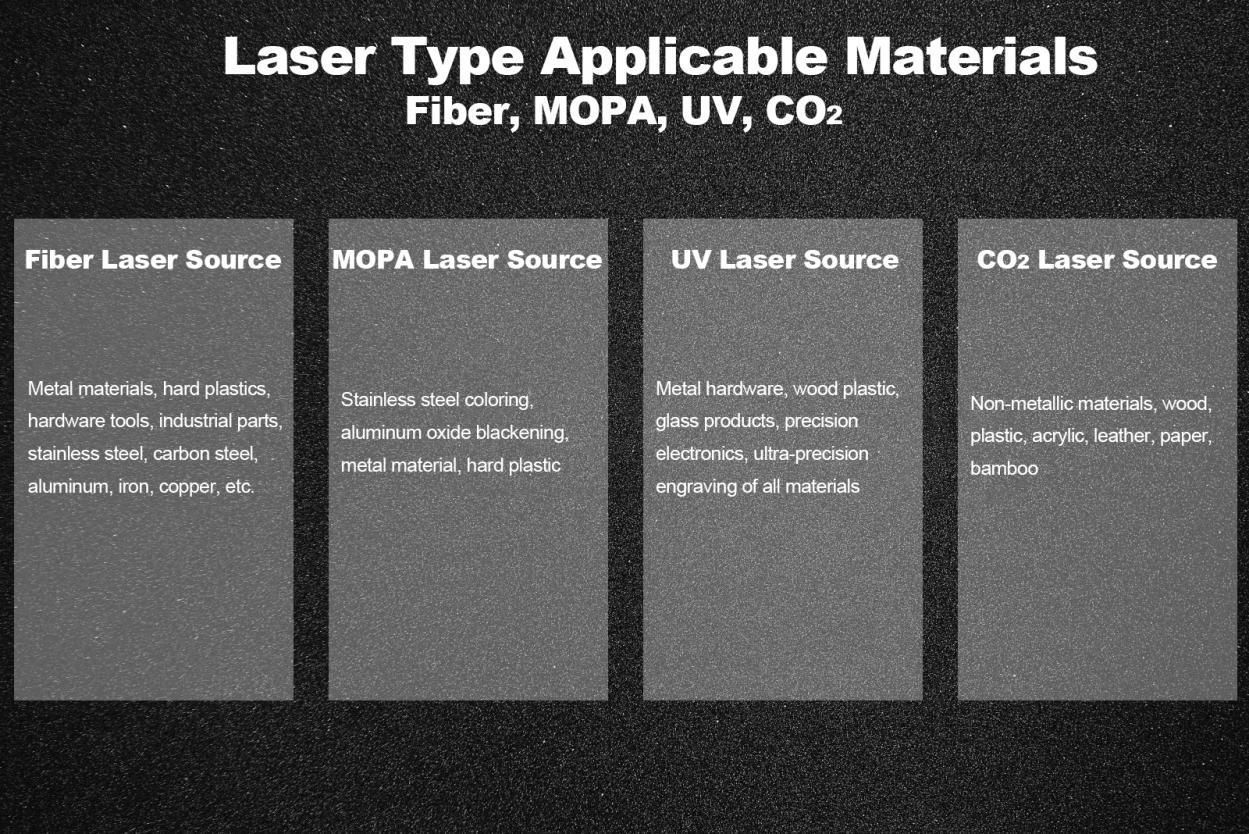

Lisebelisoa tsa mofuta oa Laser

Nts'etsopele ea laser ka nako e ts'oanang e boetse e khothaletsa nts'etsopele e potlakileng ea theknoloji ea China ea ho hloekisa ka laser, theknoloji ea ho hloekisa ka laser e boetse e fetohile theknoloji ea bohlokoahali ea ho hloekisa indastering, metsing, sebakeng sa lifofane le libakeng tse ling tsa tlhahiso ea maemo a holimo, ho kenyelletsa le ho tlosoa ha litšila tsa rabara. holim'a hlobo ea lithaere, ho tlosoa ha litšila tsa oli ea silicone holim'a filimi ea khauta le ho hloekisa ka mokhoa o nepahetseng haholo oa indasteri ea microelectronics.

Ho tlosoa ha mafome a tšepe, ho tlosa pente, ho tlosoa ha oli le ho tlosoa ha lesela la oxide ke ts'ebeliso ea morao-rao ea tšimo ea laser ea ho hloekisa. Pakeng tsa li-lasers tse fapaneng ka bolelele ba maqhubu, matla le likarolo tse ling tsa bohlokoa tsa phapang, lisebelisoa tse fapaneng, matheba a laser wavelength, matla le litlhoko tse ling li fapane, mosebetsing oa 'nete oa ho hloekisa o hloka ho khetha mekhoa e fapaneng ea ho hloekisa laser ho latela maemo a nnete.

Kamora palo e kholo ea netefatso ea liteko ke sehlopha sa lipatlisiso le nts'etsopele ea MavenLaser, laser ea MOPA, laser e kopaneng ke 'maraka o sebelisoang ka ho fetesisa oa ho hloekisa ka laser, o lateloa ke palo e nyane ea lits'ebetso tsa lasers ea carbon dioxide, ultraviolet lasers, lasers e tsoelang pele.

1.MOPA pulsed laser hloekisa bakeng sa lisebelisoa tse fapaneng tsa ho hloekisa bokaholimo

Sekoti se resontang sa tsamaiso ea laser fiber ea MOPA ka boeona ke fiber ea optical, 'me MO (Master Oscillator) ke laser ea matla a tlaase, eo ka kakaretso e khethoang bakeng sa bolelele ba eona bo loketseng. Laser LD ea matla a tlase (laser Diode) e ka fetola litekanyetso tsa tlhahiso ka kotloloho ka koloi ea hona joale, ebe leseli la lets'oao le hlahisoang ke LD le kopanngoa le sistimi ea matla a matla a PA (Power Amplifier) ka pigtail bakeng sa ho holisa leseli la matšoao.

Laser ea MOPA ke mokhoa o sebelisoang ka ho fetisisa oa ho hloekisa ka laser, hobane MOPA fiber laser sisteme e ka kopanngoa ka thata le sistimi ea mohloli oa lets'oao la peo bakeng sa ho holisa, e ke ke ea fetola litšobotsi tsa laser joalo ka bolelele ba bohareng, maqhubu a maqhubu a maqhubu le bophara ba molumo. Ka hona, tekanyo ea phetoho ea parameter e phahame ebile e pharaletse, bakeng sa maemo a fapaneng a ts'ebeliso ea lisebelisoa tse fapaneng, nako ea ho ikamahanya le maemo le ts'ebetso ea fensetere e kholo, ho kopana le tlhoekiso ea holim'a lisebelisoa tse fapaneng.

Ho feta moo, laser ea MOPA e na le moeli o phahameng oa laser eneji, e ka ntlafatsoa ka ho ntlafatsa sesebelisoa sa ho hloekisa ka laser, joalo ka ho eketsa sebaka sa ts'ebetso ea laser, ka litsamaiso tse bohlale, joalo-joalo, ho fihlela ntlafatso ea lisebelisoa tsa ho hloekisa ka laser. Ho bohlokoa ho bolela hore ka lebaka la ts'ebetso e ntle haholo le ts'ebetso e bonolo ea laser ea MOPA, e sebelisoa haholo libeteri tse ncha tsa matla le liindasteri tse ling tse ntseng li hlaha.

| Betri e Ncha ea Matla a Matla | Ho hloekisa libeteri tsa lithium, ho hloekisa litšiea, ho hloekisa boema-kepe ba metsi, ho hloekisa sekoaelo, ho hloekisa filimi e putsoa, joalo-joalo. |

|

Sepakapaka | Ho hloekisa likarolo tsa enjene pele le ka mor'a ho tjheseletsa, ho hloekisoa ha tanka ea polokelo ea koloi pele le ka mor'a ho tjheseletsa, ho tlosoa ha pente linthong tse entsoeng ka motsoako, ho tlosoa ha moemeli oa ho lokolla, ho tlosa letlalo la sefofaneng, ho tlosoa ha sealant, ho hloekisa hlobo. |

| Lihlahisoa tsa hlobo | Mefuta ea lithaere, hlobo ea li-encapsulation, hlobo ea ente, hlobo e koalang lesale, hlobo ea lijo, joalo-joalo ho tlosa carbon layer. |

| Indasteri ea 3C | Khetho ea boto ea potoloho le ho tlosa pente, ho hloekisa liphaephe, ho tlosa pente ea mokotla oa selefouno, ho hloekisa jig ea PVD |

| Ho Etsa Likoloi | Ho hloekisa 'mele pele ho weld, ho hloekisa mabili, ho tlosa pente libakeng tse khethiloeng tsa' mele, lithaere tse khutsitseng |

| Likepe Tsa Leoatleng | Ho hloekisa pele ho weld le post-weld, ho tlosa likarolo tsa pente, ho hloekisa ho tlosa oli |

| Borokho, tlhokomelo ea litsela tse kholo | Likarolo tsa sebopeho sa borokho ho tlosa pente, ho tlosa mafome, ho tlosoa ha pente ea tsela e kholo |

| Lipalangoang tsa Terene | Ho hloekisa 'mele oa aluminium pele le ka mor'a ho cheselletsa, ho hloekisa mabili ka boiketsetso, ho hloekisa bogie, ho hloekisa koloi, joalo-joalo. |

| Petrochemicals | Ho tlosoa ha sethala sa oli se kantle ho naha, ho tlosa pente ea liphaephe, ho tlosa mafome, joalo-joalo. |

| Indasteri ea Lijo | Lipane tsa ho baka ka tšepe, hlobo, joalo-joalo. |

| Komiki ea vacuum | Ho tlosoa ha pente e ka tlaase le ea lebota ea likopi tse insulated |

| Liindasteri tse ling | Sefahla sa oli ea tšepe, tlhoekiso ea li-filter tube, polishing ea tšepe e sa hloekang, ho tlosa mafome a laser, ho tlosoa ha oxide |

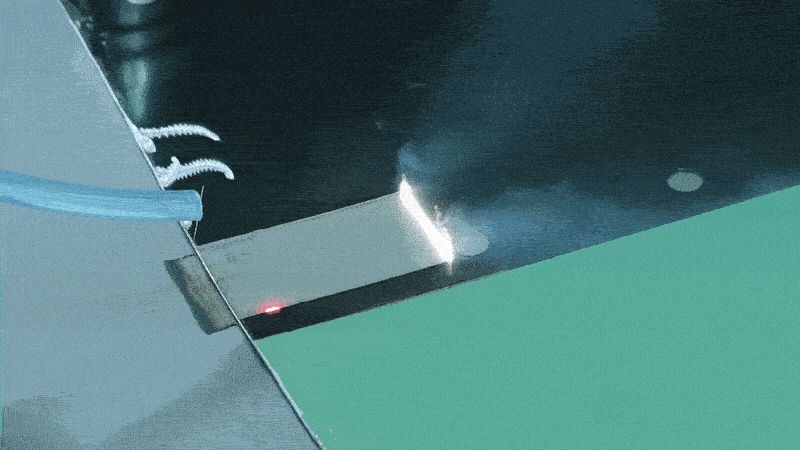

2.Composite laser ho hloekisa, khetho e ntle ka ho fetisisa ea ho tlosa pente

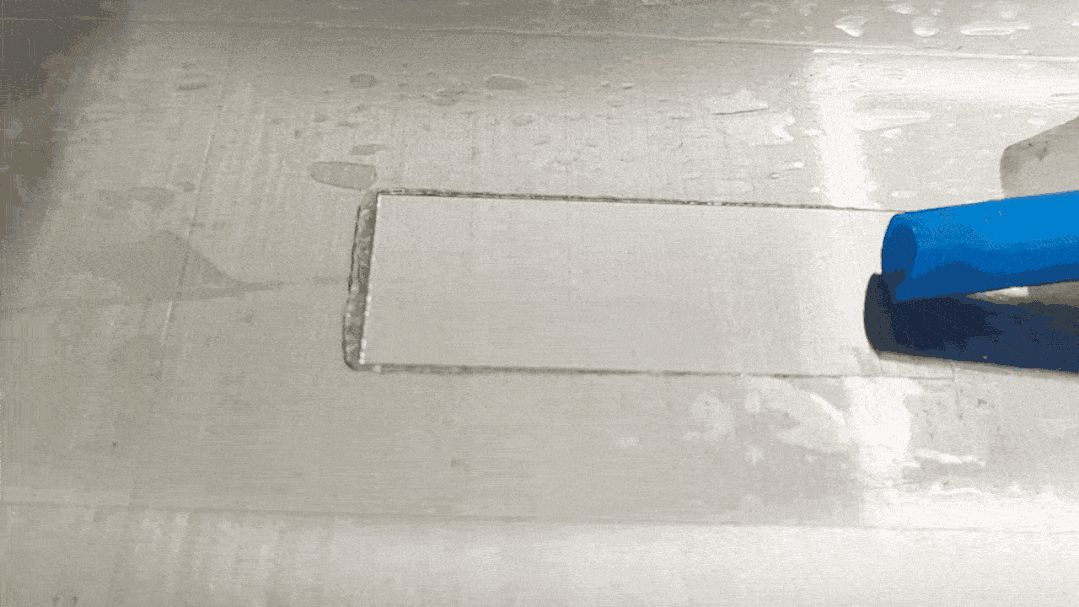

Laser composite hloekisa ka semiconductor tsoelang pele laser e le mocheso phetiso phallo, e le hore likhomaretsi ho hloekisoa monya matla a ho hlahisa vaporization, plasma maru, le sebopeho sa mocheso katoloso ea khatello ea mocheso pakeng tsa thepa ea tšepe le sekhomaretsi, ho fokotsa matla a tlamahano pakeng tsa. mekhahlelo e 'meli. Ha laser output high-energy pulse laser beam, sephetho le vibration shock wave e le hore bond ha se likhomaretsi tse matla ka ho toba ho tloha holim'a tšepe, kahoo ho finyella ka potlako ho hloekisa laser.

Ho tlosa pente ea khetla ea matla

Laser composite hloekisa ha e ntse e tsoela pele laser le pulse laser e sebetsang ka motsoako, ho etsa 1 + 1> 2 litšobotsi tsa ho sebetsa. Lebelo le potlakileng, ts'ebetso e phahameng, boleng bo ts'oanang ba ho hloekisa, bakeng sa lisebelisoa tse fapaneng, o ka sebelisa li-wavelengths tse fapaneng tsa ho hloekisa laser ka nako e le 'ngoe ho fihlela sepheo sa ho tlosa matheba.

Ho tlosa pente bakeng sa li-motors tsa hairpin

Hajoale, ho hloekisoa ha motsoako oa laser ho sebelisoa haholo likepeng, ho lokisa likoloi, hlobo ea rabara, lisebelisoa tsa mochini o phahameng haholo, ts'ireletso ea seporo le tikoloho le masimo a mang, ka nepo ho tlosa resin ea holim'a ntho, pente, oli, matheba, litšila, mafome. , plating le oxide layer.

Mohlala, ho hloekisoa ha laser e teteaneng ka laser e le 'ngoe, theko e phahameng, tšebeliso ea pulsed laser - semiconductor laser composite clean, e ka ntlafatsa boleng ba ho hloekisa kapele le ka katleho, mme ha e bake tšenyo ho substrate; ka motsoako oa aluminium le lisebelisoa tse ling tse bonahatsang haholo ka laser ho hloekisa, ho bonahatsa laser e le 'ngoe le mathata a mang. Tšebeliso ea pulsed laser - semiconductor laser compound hloekisa, ka karolo ea semiconductor laser thermal conductivity transfer, eketsa lebelo la ho monya matla a tšepe holim'a oxide layer, e le hore pulse laser beam e ka ba kapele ho hlobolisa lera la oxide, ho ntlafatsa ka katleho ts'ebetso ea ho tlosa, haholo-holo ntle le ts'ebetso ea pente e eketsehile ka makhetlo a fetang 2.

3.Carbon dioxide laser hloekisa, khetho e ntle ka ho fetisisa ea ho tlosa lisebelisoa tse se nang tšepe

Li-laser tsa CO2 ke lilase tsa khase tse nang le khase ea CO2 e le ntho e sebetsang, e tlatsitsoeng ka khase ea CO2 le likhase tse ling tse thusang (helium le naetrojene le palo e nyane ea haedrojene kapa xenon), tse nang le tataiso e ntle, monochromaticity le botsitso ba khafetsa. Kaha hangata tube ea ho ntša e entsoe ka lisebelisoa tsa khalase kapa tsa quartz, mefuta e 'meli e tloaelehileng ea li-lasers tsa CO2 ke li-laser tsa CO2 tsa khalase le tšepe ea RF tube CO2 lasers.

Ho tlosa marinini

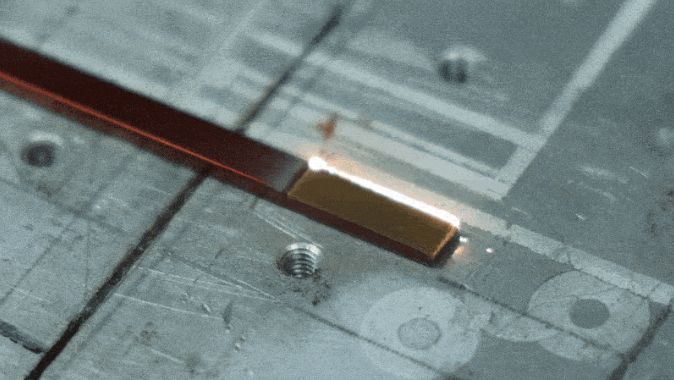

4.UV ho hloekisa ka laser bakeng sa lisebelisoa tse nepahetseng

Li-laser tse ka sehloohong tsa UV tse sebelisetsoang laser microfabrication ke li-excimer lasers le all-solid-state lasers. Laser ea UV e nang le wavelength e khuts'oane le matla a phahameng a photon a le mong a ka senya ka ho toba litlamo tsa lik'hemik'hale tse hokahaneng pakeng tsa thepa, 'me lisebelisoa li tlosoa holimo ka mokhoa oa khase kapa likaroloana,' me sebaka se amehileng ke mocheso se hlahisoang nakong ea ts'ebetso se nyane, se nang le melemo e ikhethang ho microfabrication, joalo ka Si, GaN le lisebelisoa tse ling tsa semiconductor, quartz, safire le likristale tse ling tsa optical, le polyimide (PI), polycarbonate. (PC) le lisebelisoa tse ling tsa polymer, 'me li ka ntlafatsa boleng ba tlhahiso ka katleho.

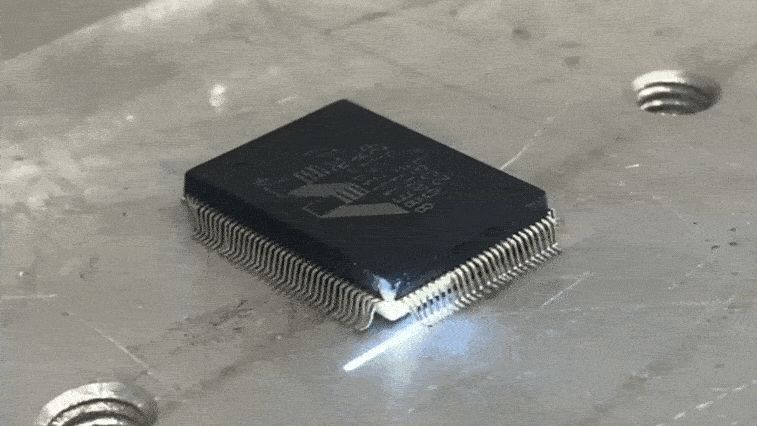

Ho hloekisa pin pin

UV laser e nkoa e le tharollo e molemo ka ho fetisisa ea ho hloekisa ka laser tšimong ea lisebelisoa tsa elektronike tse nepahetseng, theknoloji ea eona e ntle ka ho fetisisa e "batang" ha e fetole thepa ea 'mele ea ntho ka nako e le' ngoe, ho sebetsa ka holimo ho micro-processing le ho sebetsa. e sebelisoe haholo liindastering le mafapheng a fapaneng joalo ka likhokahano, optics, sesole, lipatlisiso tsa botlokotsebe, bongaka. Mohlala, mehla ea 5G e thehile tlhoko ea 'maraka bakeng sa ts'ebetso ea FPC. Ts'ebeliso ea mochini oa laser oa UV e etsa hore ho khonehe bakeng sa ts'ebetso e nepahetseng e batang ea FPC le lisebelisoa tse ling.

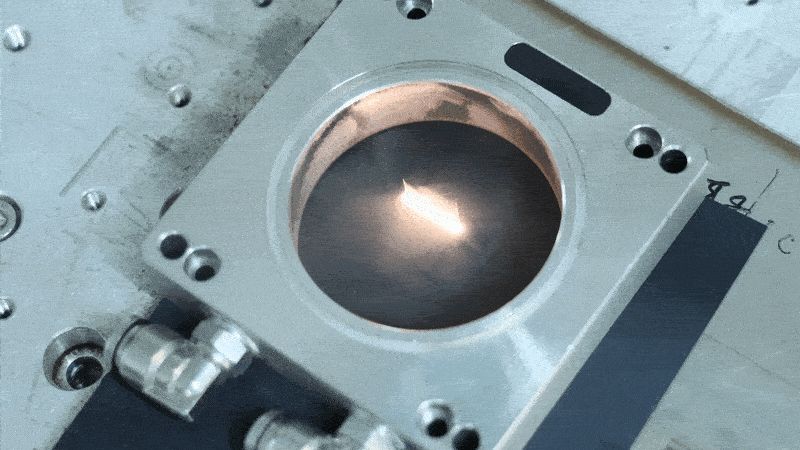

5.Continuous fiber laser hloekisa ho tlosa mafome a phaphametseng holim'a tšepe

Fiber laser e tsoelang pele e sebetsa ka ho pompa leseli ho tsoa mohloling oa pompo ka sebonela-pele se kopantsoeng le sebaka sa ho fumana chelete, hobane sebaka sa ho fumana chelete ke fiber e sa tloaelehang ea lefats'e, ka hona lebone la pompo le kenngoa, 'me matla a photon a sa tloaelehang a lefatše a qhoma. 'me u finyelle phetoho ea palo ea likaroloana, ka mor'a ho kheloha ha karoloana ka har'a sekoti sa resonant, ho tloha sebakeng se thabileng ho qhomela ho khutlela sebakeng sa fatše, ho lokolla matla, le ho theha tlhahiso e tsitsitseng ea laser, molemo o moholo ke hore. leseli le ka tsoela pele.

Ho hloekisa ka mor'a weldingC

Lisebelisoa tsa 'nete tsa ho hloekisa ka laser, ts'ebeliso e tsoelang pele ea fiber laser e tlase, empa ho na le palo e nyane ea lits'ebetso, joalo ka meaho e meholo ea tšepe, liphaephe, joalo-joalo, ka lebaka la bongata bo boholo ba ho qhala mocheso ka potlako, litlhoko tsa tšenyo ea substrate ha li joalo. e phahameng, joale u ka khetha laser e tsoelang pele.

Ho Tlosa Mafome

Ke habohlokoa ho bolela hore ka katleho le botsitso ba thekenoloji ea letheba la letheba, ring fiber laser e nang le melemo ea phetoho e bonolo ea ts'ebetso le ts'ebetso e bonolo e 'nile ea tsebahala haholo tšimong ea ho cheselletsa le ho hloekisa,' me ka mor'a liteko tse ngata tse entsoeng ke Baenjiniere ba MavenLaser Process Center, theknoloji e sebelisoa ho tlosa mafome a phaphametseng, a ka ntlafatsang haholo ts'ebetso ea ho hloekisa.

Ka tsoelo-pele ea saense le thekenoloji le ntlafatso ea litlhoko tsa ts'ireletso ea tikoloho, ho hloekisa ka laser ho tla nka karolo ka botebo le ka mokhoa o pharaletseng ts'ebetsong ea tlhahiso ea indasteri ea tlhahiso ea Chaena, 'me e be mokhoa o ka sehloohong oa ho hloekisa oa tlhahiso e hloekileng ea indasteri.

Shenzhen Maven Laser Automation Co., Ltd., e ikarabellang ho Shenzhen, e na le setsi sa eona sa tlhahiso. E tsepamisitse maikutlo tšimong ea lisebelisoa tsa theknoloji e phahameng ea laser, ka sepheo sa ho hlahisa lihlahisoa e le sepheo sa mantlha, ho fana ka bareki ka laser ho itšeha, laser tjheseletsa, laser tšoaea, laser hloekisa, ka laser phepelo ea matla ka sete e feletseng ea litšebeletso tse thehiloeng ho tharollo ea laser. ho tlhokahalo ea bareki, nts'etsopele ea lenaneo la ho hloekisa ka boiketsetso ho fihlela merero e bohlale ea ho hloekisa. Lefapheng la mochine oa ho hloekisa laser ke boemo bo ka sehloohong, lihlahisoa tsa eona li kenyelletsa mochine oa ho hloekisa laser oa mofuta oa khabinete, mochine oa ho hloekisa oa mofuta oa laser, mokokotlo oa mokokotlo oa mofuta oa laser oa ho hloekisa mochine o fapaneng oa ho sebelisa mochine oa ho hloekisa laser. Sistimi e phethahetseng ea ho bapatsa le sistimi ea ts'ebeletso ea kamora thekiso ho etsa hore lihlahisoa li be le tlholisano, lihora tse 24 ka nako efe kapa efe ho arabela ho u fa letoto la lits'ebeletso tsa ho lokisa lihlahisoa kamora thekiso. Theknoloji ea MavenLaser e tla u khahla ka boleng bo tsitsitseng ba theknoloji, theko e tlase ea ts'ebeletso, 'me u be molekane oa hau ea tšepahalang!

Nako ea poso: Jan-16-2023