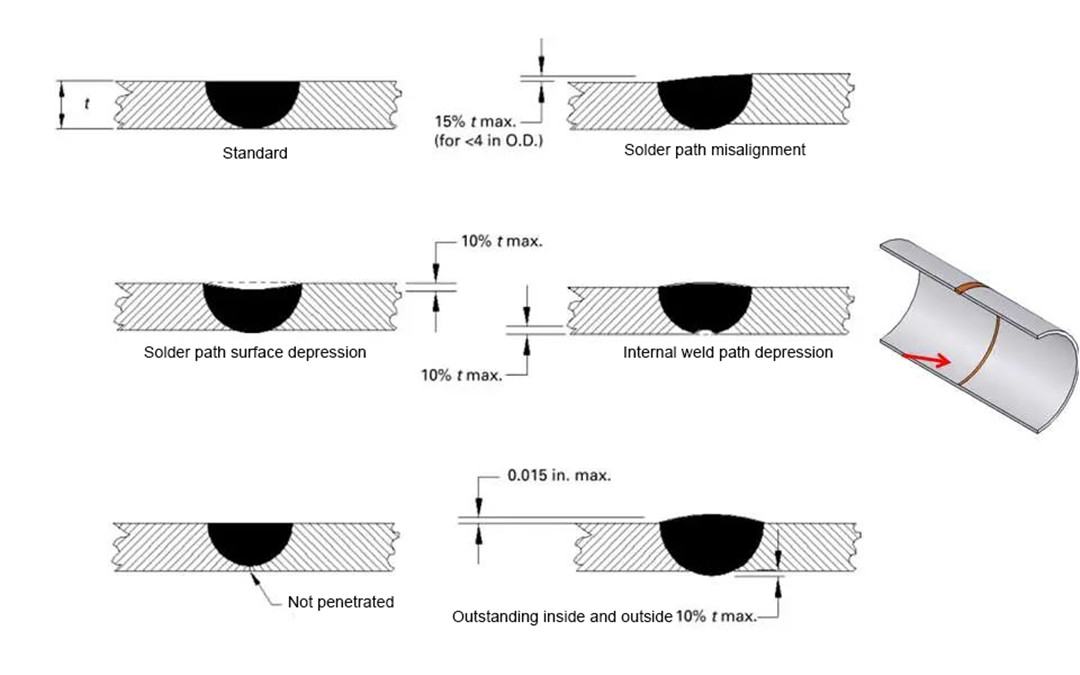

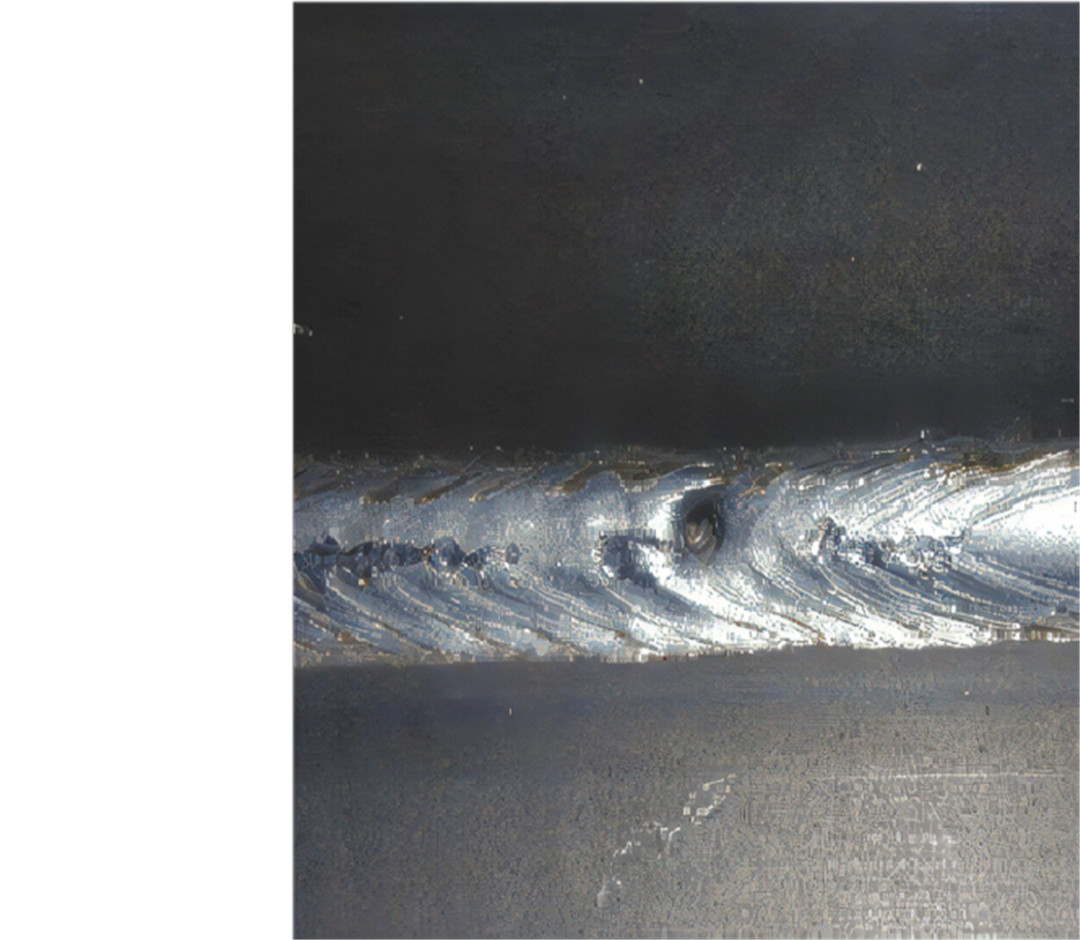

1. Bothata: Slag splash

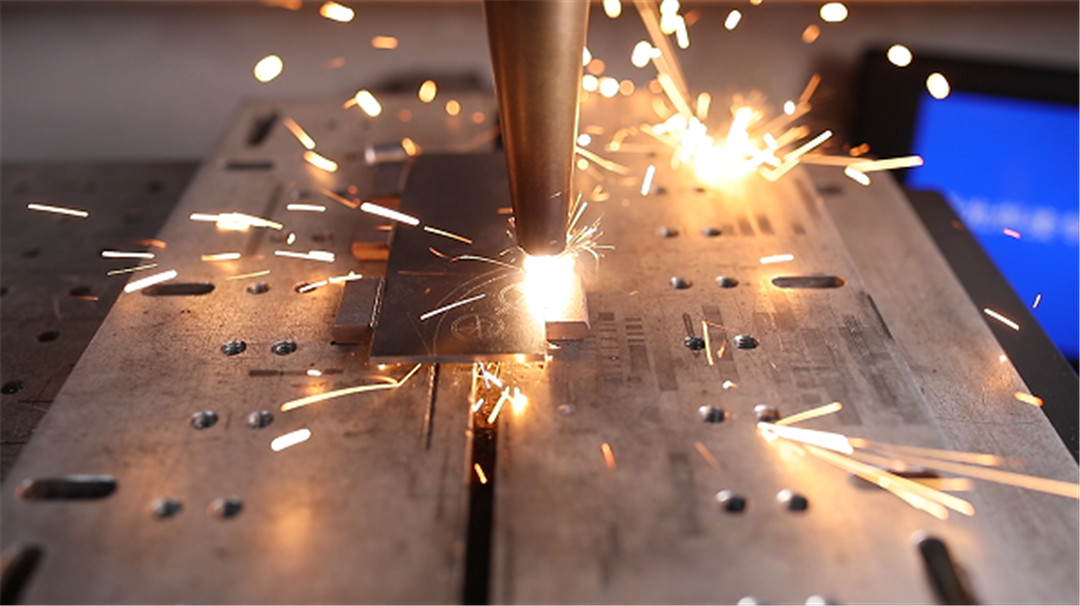

Ts'ebetsong ea laser welding, thepa e qhibilihisitsoeng e phatloha hohle 'me e khomarela holim'a thepa, e etsa hore likaroloana tsa tšepe li hlahe holim'a metsi le ho ama botle ba sehlahisoa.

Sesosa sa bothata: spatter e ka 'na ea e-ba ka lebaka la matla a feteletseng a bakang ho qhibiliha ka potlako, empa hape hobane sebaka sa thepa ha se hloeke, kapa khase e matla haholo.

Tharollo: 1, phetoho e nepahetseng ea matla; 2, ela hloko ho hloekisa holim'a lintho tse bonahalang; 3, fokotsa khatello ea khase.

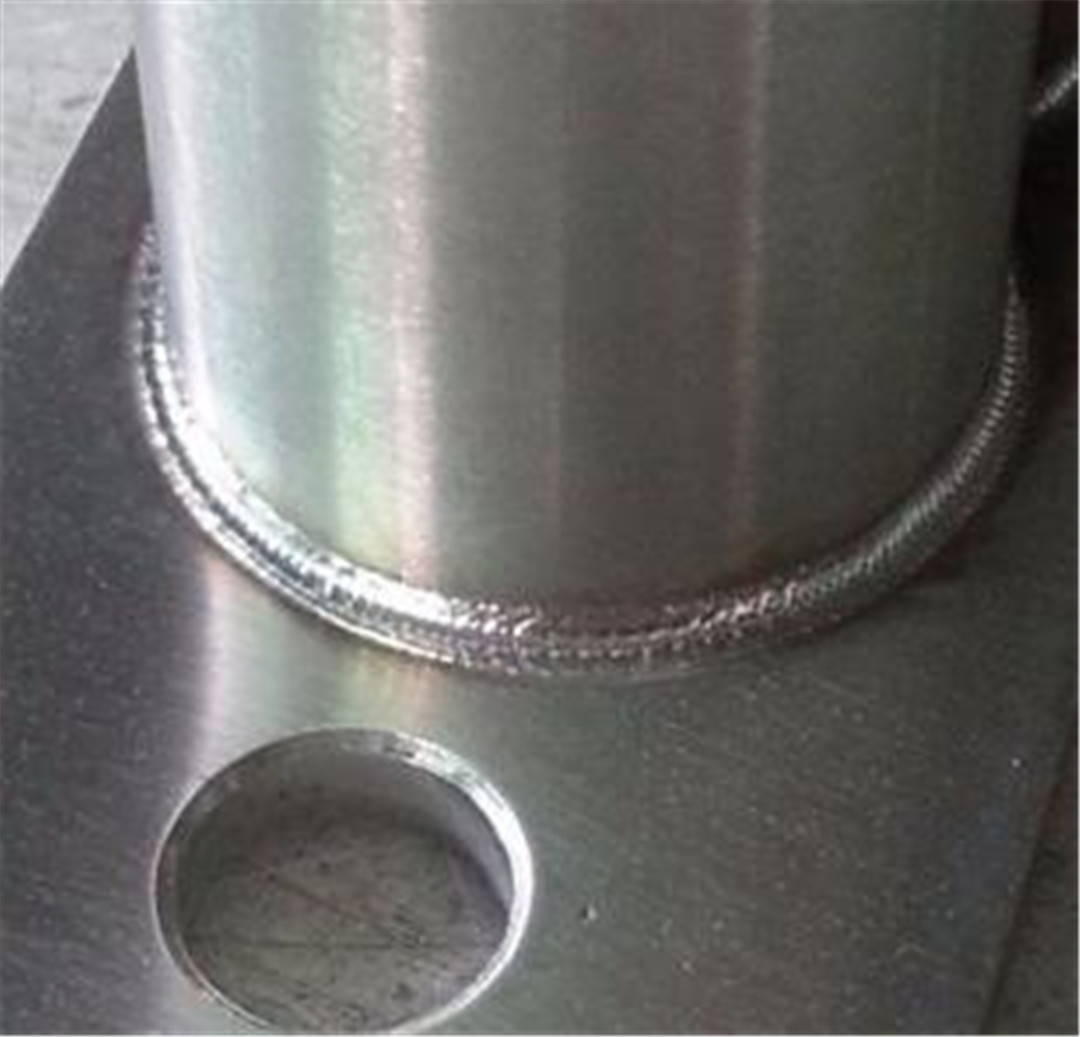

2. Bothata: The weld seam e phahame haholo

Welding e tla fumana hore seam weld se phahame haholo ho feta boemo bo tloaelehileng, e leng se hlahisang seam se nang le mafura, se shebahalang se sa khahle haholo.

Lebaka la bothata: lebelo la phepelo ea terata le potlakile haholo, kapa lebelo la welding le butle haholo.

Tharollo: 1. Fokotsa lebelo la phepelo ea terata tsamaisong ea taolo; 2. Eketsa lebelo la tjheseletsa.

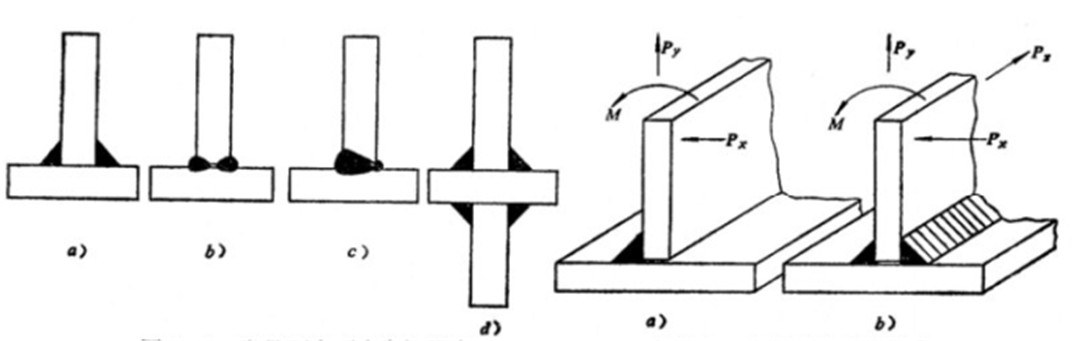

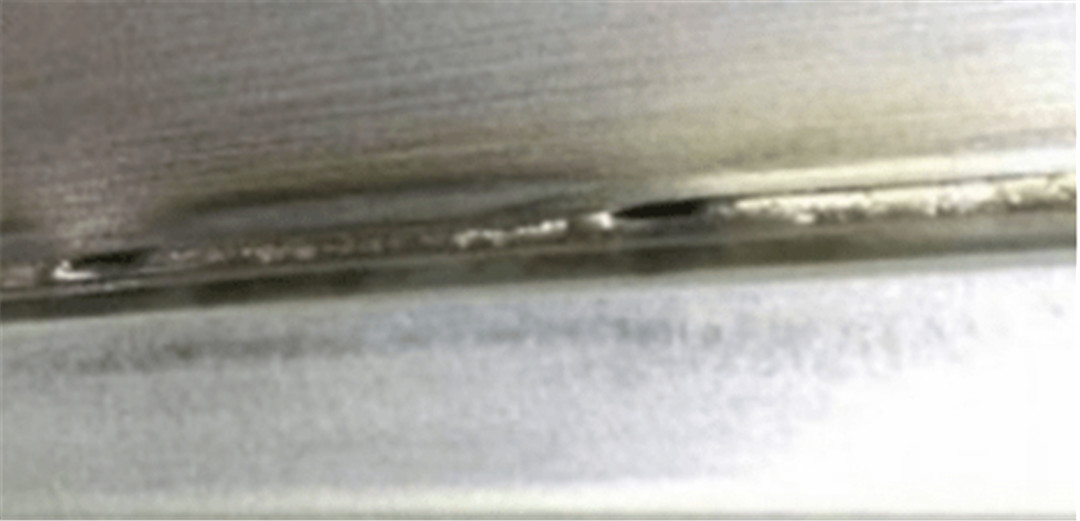

3. Bothata: Welding offset

Ho tjheseletsa ntle le ho tiisa manonyeletso a sebopeho le boemo bo sa nepahaleng ho ka lebisa ho hloleheng ho felletseng ha tjheseletsa.

Sesosa sa bothata: boemo bo sa nepahalang nakong ea welding; boemo bo sa tsitsang ba ho fepa ka terata le mahlaseli a laser.

Tharollo: 1. Fetola laser offset le swing angle ka boto; 2. Lekola kamano pakeng tsa terata le hlooho ea laser bakeng sa ho kheloha.

4. Bothata: 'Mala oa weld o lefifi haholo

Ha ho cheselletsa tšepe e sa hloekang, motsoako oa aluminium le lisebelisoa tse ling, 'mala oa weld o lefifi haholo o tla etsa hore weld le bokaholimo bo hlahise phapang e matla, e ama botle haholo.

Lebaka la bothata: matla a laser a manyane haholo a bakang mollo o sa lekaneng, kapa lebelo la welding le potlakile haholo.

Tharollo: 1. fetola matla a laser; 2. fetola lebelo la tjheseletsa.

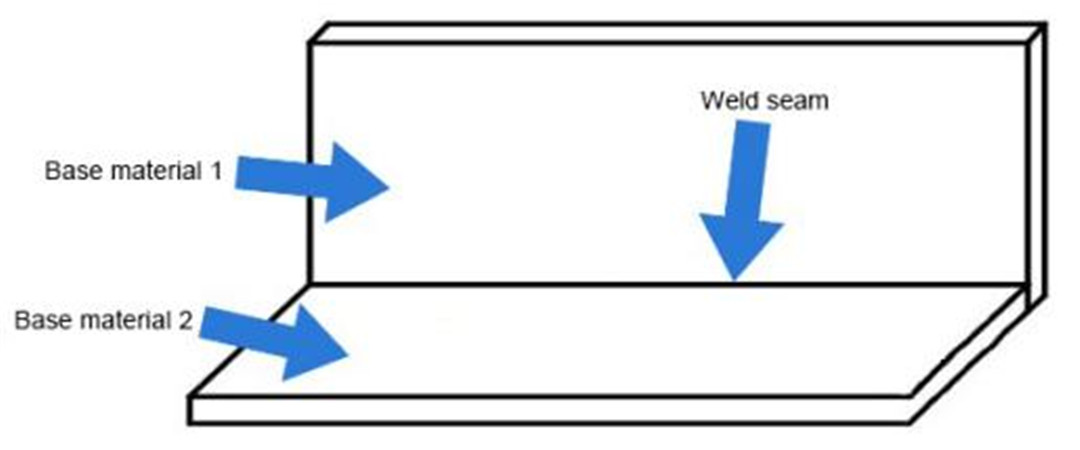

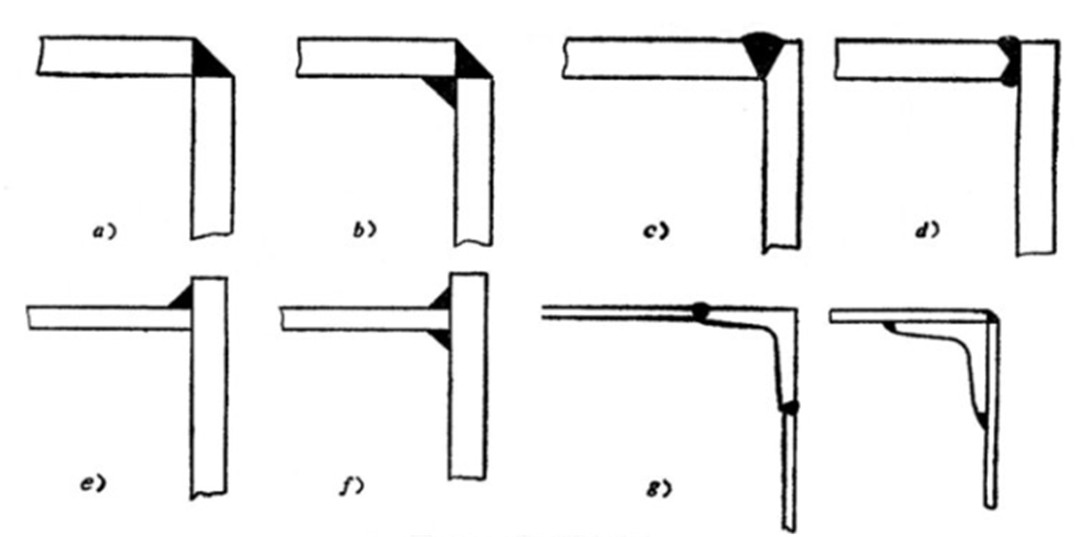

5. Bothata: Ho se leka-lekane ho tjheseletsa sekhutlo

Ha ho tjheseletsa likhutlong tse ka hare le ka ntle, likhutlong ha li lokisoe ho lebelo kapa boemo, tse ka lebisang habonolo ho tjheseletsa ho sa lekanang likhutlong, tse amang matla a weld le botle ba chese.

Sesosa sa bothata: boemo bo sa thabiseng ba welding.

Tharollo: Fetola tokiso ea ho tsepamisa mohopolo ho sistimi ea taolo ea laser e le hore hlooho ea laser e ts'oaroang ka letsoho e tsebe ho etsa ts'ebetso ea welding ka thoko.

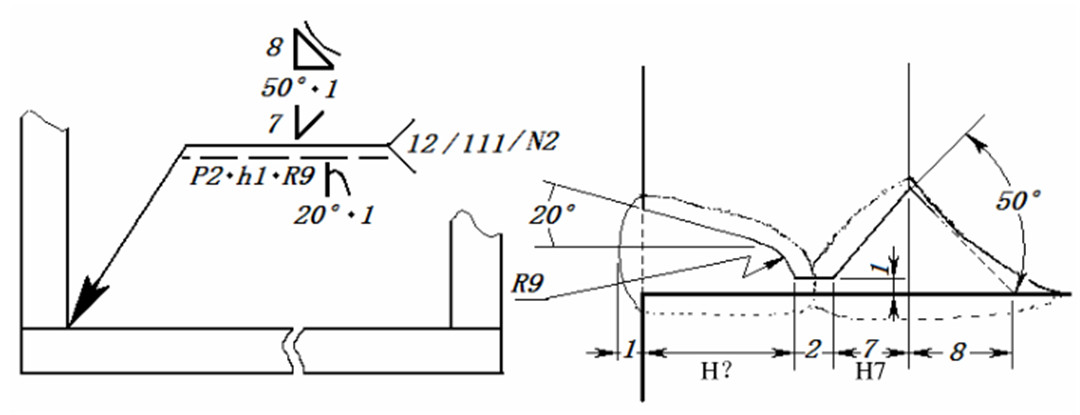

6. Bothata: tjheseletsa seam ho tepella maikutlo

Dents ka kopanelo welded tla lebisa matla a sa lekaneng a tjheseletsa le lihlahisoa tse sa tšoanelehang.

Sesosa sa bothata: Matla a laser a maholo haholo, kapa laser focus e behiloe ka tsela e fosahetseng, e leng se etsang hore letamo la ho qhibiliha le be tebileng haholo 'me thepa e qhibilihe ho feta tekano, e leng se lebisang ho teteaneng ha seam seam.

Tharollo: 1. Fetola matla a laser; 2. Fetola ho tsepamisa mohopolo oa laser.

7. Bothata: botenya ba weld ha bo tšoane

Weld seam ka linako tse ling e kholo haholo, ka linako tse ling e nyane haholo, kapa ka linako tse ling e tloaelehile.

Sesosa sa bothata: phepelo ea lebone kapa terata ha se bothata.

Tharollo: Lekola botsitso ba laser le terata feeder, ho kenyeletsoa voltage ea phepelo ea motlakase, sistimi e pholisang, sistimi ea taolo, terata ea fatše, jj.

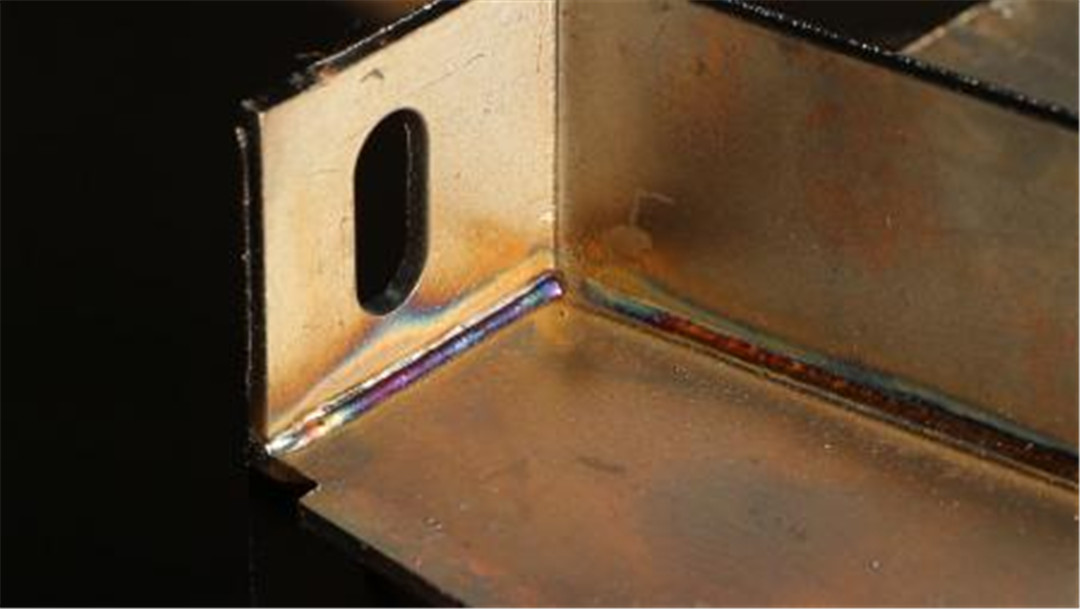

8. Bothata: Ho loma bohale

Loma bohale e bua ka tjheseletsa le lintho tse bonahalang e sa hantle ho kopantswe, beveling le maemo a mang, kahoo ama boleng ba tjheseletsa.

Sesosa sa bothata: lebelo la welding le potlakile haholo, ho fella ka hore letamo la ho qhibiliha le se ke la aroloa ka mahlakoreng ka bobeli a thepa, kapa lekhalo la thepa le leholo, thepa ea ho tlatsa ha e lekane.

Tharollo: 1. Fetola matla le lebelo la laser ho ea ka matla a thepa le boholo ba seam weld; 2. Etsa mosebetsi oa ho tlatsa kapa oa ho lokisa hamorao.

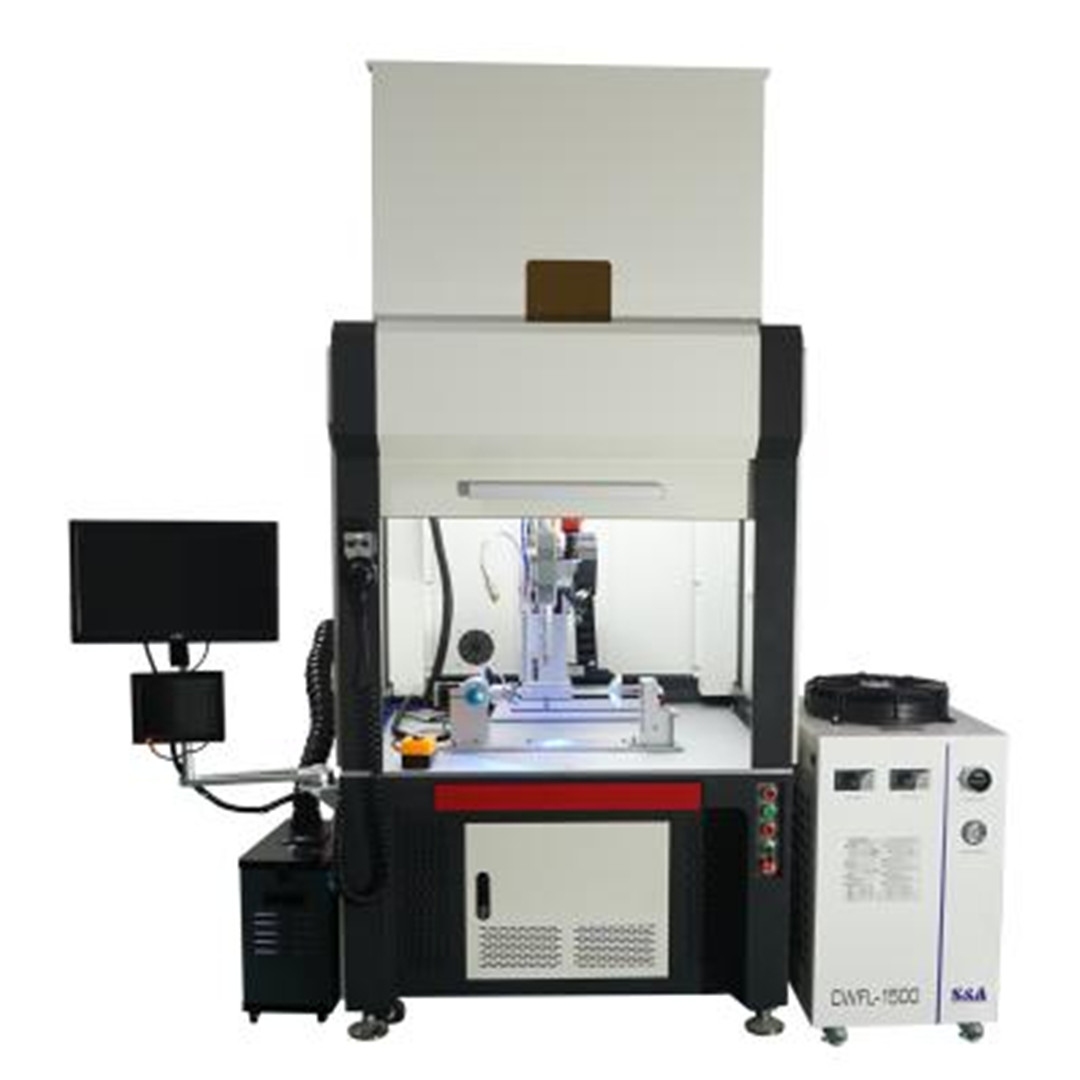

Maven Laser Automation Co.,Ltd. (Maven laser ka bokhutšoane) ke moetsi ea ka sehloohong oa lisebelisoa tsa laser le litharollo tsa litsebi tsa boiketsetso, tse teng Shenzhen, Chaena, tse thehiloeng ka 2008. Lihlahisoa tsa rona tsa litsebi ke: mochine oa ho hloekisa ka laser, mochine oa welding oa laser, mochine oa ho roka liroboto le mochini oa ho tjheseletsa sethaleng, haeba u na le lipotso leha e le life tsa setsebi, u amohelehile ho buisana le rona.

Nako ea poso: Nov-18-2022