Joalo ka sejari sa likarolo tse ling tsa koloi, theknoloji ea tlhahiso ea 'mele oa koloi e khetha ka kotloloho boleng ba kakaretso ba koloi. Ts'ebetsong ea ho etsa 'mele oa likoloi, ho cheselletsa ke mokhoa oa bohlokoa oa tlhahiso. Theknoloji ea ho tjheseletsa ha joale e sebelisoang bakeng sa ho cheselletsa 'mele haholo-holo e kenyelletsa welding spot welding, welding e sirelelitsoeng ka gase e qhibilihisitsoeng (MIG welding) le welding e entsoeng ka khase e sirelelitsoeng ka arc (welding ea MAG) hammoho le welding ea laser.

Joalo ka theknoloji e tsoetseng pele ea ho tjheseletsa e nang le kopanyo ea optical-mechanical, thekenoloji ea welding ea laser e na le melemo ea matla a mangata a matla, lebelo le potlakileng la ho cheselletsa, khatello e tlaase ea welding le deformation, le ho feto-fetoha ha maemo ha ho bapisoa le theknoloji ea khale ea ho tjheseletsa 'mele.

Sebopeho sa 'mele oa koloi se rarahane, 'me likarolo tsa' mele li na le likarolo tse tšesaane tse nang le mabota le tse kobehileng. Auto body welding e tobane le mathata a ho cheseletsa joalo ka ho fapana ha thepa ea 'mele, botenya bo fapaneng ba likarolo tsa' mele, litselana tse fapaneng tsa ho cheselletsa le mefuta e kopaneng. Ntle le moo, ho cheselletsa 'mele oa likoloi ho na le litlhoko tse phahameng mabapi le boleng ba welding le katleho ea welding.

Ho ipapisitsoe le liparamente tse loketseng tsa ts'ebetso ea welding, welding ea laser e ka netefatsa matla a mokhathala o phahameng le ho ba le tšusumetso e matla ea likarolo tsa mantlha tsa 'mele ha li cheseletsa, ka hona ho netefatsa boleng le bophelo ba ts'ebeletso ea ho cheselletsa 'mele. Theknoloji ea welding ea laser e ka ikamahanya le tjheseletso ea likarolo tsa 'mele oa koloi ka mefuta e fapaneng ea manonyeletso, botenya bo fapaneng le mefuta e fapaneng ea thepa, e fihlelang tlhoko ea ho tenyetseha ha ho etsoa 'mele oa likoloi. Ka hona, theknoloji ea welding ea laser ke mokhoa oa bohlokoa oa tekheniki oa ho fihlela nts'etsopele ea boleng bo holimo ea indasteri ea likoloi.

Laser welding process bakeng sa 'mele ea likoloi

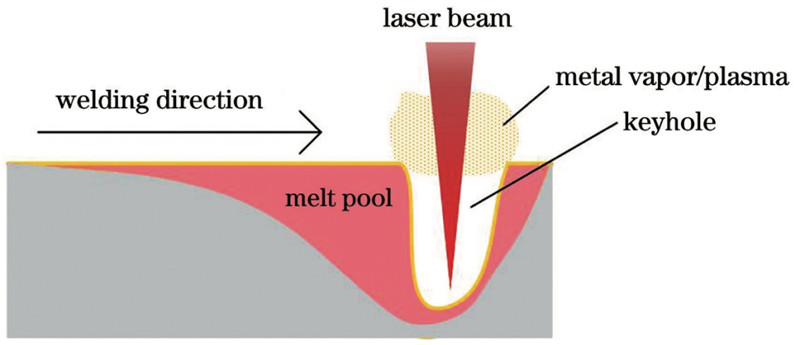

Laser deep fusion welding process molao-motheo: Ha matla a laser a matla a fihla boemong bo itseng, bokaholimo ba lintho bo fetoha mouoane, kahoo bo etsa lesoba la senotlolo. Ha khatello ea mouoane ka har'a sekoti e fihla ho lekana ka matla le khatello e tsitsitseng le tsitsipano ea holim'a mokelikeli o potolohileng, laser e ka khantša ka lesoba la senotlolo ho ea tlase ho lesoba, 'me ka ho tsamaea ha lebone la laser, weld e tsoelang pele thehoa. Ts'ebetsong ea welding ea laser deep fusion, ha ho na lebaka la ho kenyelletsa flux e thusang kapa filler ho tjheseletsa thepa ea sesebelisoa hore e be e le 'ngoe.

The weld seam e fumanoang ka laser deep fusion welding hangata e boreleli ebile e otlolohile ka deformation e nyane, e thusang ho ntlafatsa ho nepahala ha tlhahiso ea 'mele oa koloi. Matla a tsitsitseng a weld a phahame, a netefatsang boleng ba ho cheselletsa 'mele oa koloi. Lebelo la welding le potlakile, e leng se loketseng ho ntlafatsa katleho ea tlhahiso ea welding.

Ts'ebetsong ea ho tjheseletsa 'mele oa koloi, ts'ebeliso ea laser deep fusion welding process e ka fokotsa haholo palo ea likarolo, hlobo le lisebelisoa tsa welding, ka hona ho fokotsa boima ba 'mele le litšenyehelo tsa tlhahiso. Leha ho le joalo, ts'ebetso ea welding ea laser deep fusion ha e mamelle lekhalo la kopano ea likarolo tse lokelang ho chesetsoa, 'me lekhalo la kopano le hloka ho laoloa pakeng tsa 0.05 le 2 mm. Haeba lekhalo la kopano le le leholo haholo, ho tla ba le mefokolo ea welding joalo ka porosity.

Lipatlisiso tsa morao-rao li bonts'a hore 'meleng oa koloi oa thepa e tšoanang, ka ho ntlafatsa litekanyetso tsa laser deep-fusion welding, hoa khoneha ho fumana weld e nang le sebopeho se setle sa bokaholimo, mefokolo e fokolang ea ka hare le thepa e babatsehang ea mochine. Thepa e ntle haholo ea mochini oa weld e ka fihlela litlhoko tsa ts'ebeliso ea likarolo tsa 'mele oa koloi. Leha ho le joalo, ho tjheseletsa 'mele oa koloi, aluminium alloy-tšepe e le moemeli oa ts'ebetso ea welding ea tšepe e tebileng ea laser ha e hōlile, le hoja ka ho eketsa lesela la phetoho e ka fumana ts'ebetso e babatsehang ea weld, empa lisebelisoa tse fapaneng tsa phetoho ea phetoho holim'a IMC layer influence mechanism le phello ea eona ho sebopeho se senyenyane sa mochini oa weld ha e hlake, e hloka boithuto bo tebileng.

Auto Body Laser Wire Filling Welding Process

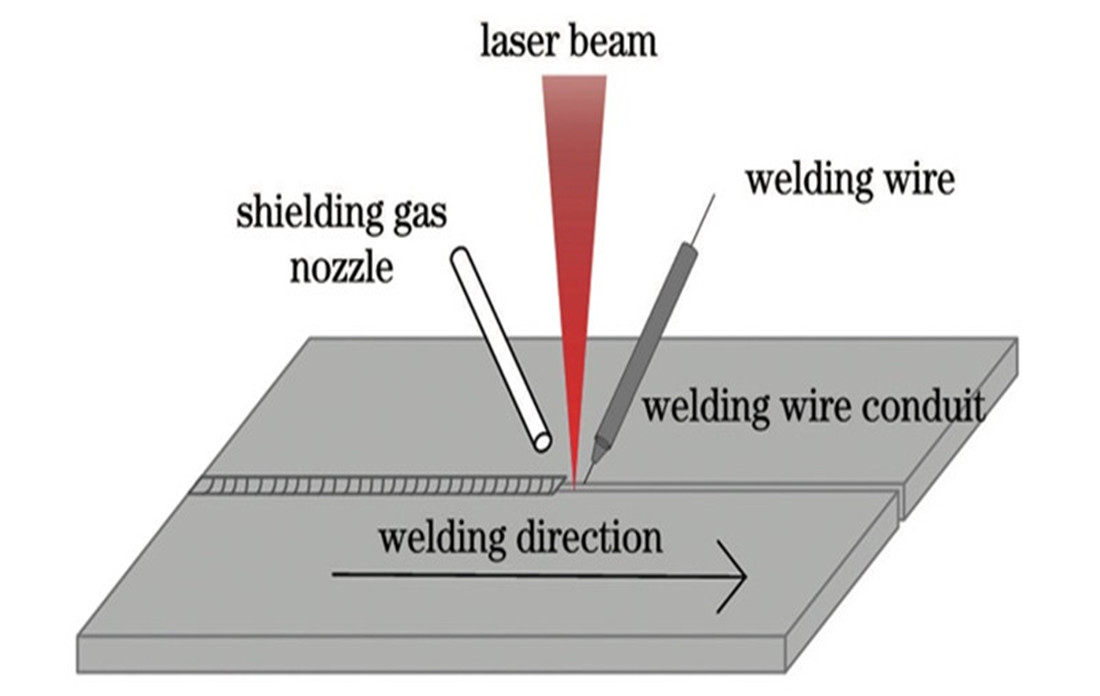

Ts'ebetso ea welding ea laser filler e thehiloe holim'a molao-motheo o latelang: Lenonyeletso le cheselitsoeng le thehoa ka ho tlatsa weld pele ka terata e itseng kapa ka ho fepa terata ka nako e le 'ngoe nakong ea ts'ebetso ea laser welding. Sena se lekana le ho fepa palo e batlang e lekana ea terata ka har'a letamo la weld nakong ea laser deep fusion welding. Setšoantšo se ka tlase se bonts'a ts'ebetso ea welding ea laser filler.

Ha ho bapisoa le laser deep fusion welding, laser filler welding e na le melemo e 'meli ho welding ea' mele oa koloi: ea pele, e ka ntlafatsa haholo mamello ea lekhalo la kopano pakeng tsa likarolo tsa 'mele oa koloi hore li be li cheselle le ho rarolla bothata ba tlhokahalo e phahameng ea bevel gap bakeng sa laser deep fusion welding. ; ea bobeli, e ka ntlafatsa kabo ea linama sebakeng sa weld ka ho sebelisa lithapo tse nang le dikahare tse fapaneng tsa sebopeho, ebe e laola ts'ebetso ea weld.

Ts'ebetsong ea ho etsa 'mele oa likoloi, ts'ebetso ea welding ea laser e sebelisoa haholo ho tjheseletsa alloy ea aluminium le likarolo tsa tšepe tsa' mele. Haholo-holo ts'ebetsong ea welding ea likarolo tsa aluminium alloy ea 'mele oa koloi, tsitsipano e kaholimo ea letamo le qhibilihisitsoeng e nyane, e ka lebisang ho putlama ha letamo le qhibilihisitsoeng, athe ts'ebetso ea welding ea laser filler e ka rarolla bothata ba ho putlama ha letamo. ka ho qhibiliha ha terata ts'ebetsong ea welding ea laser.

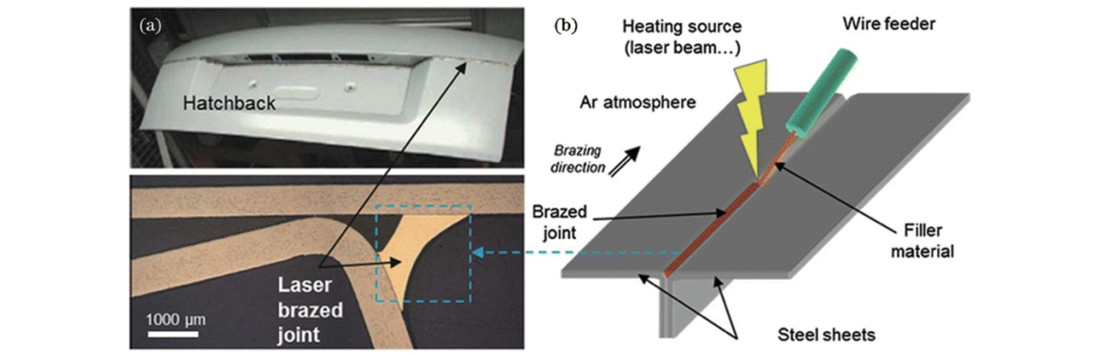

Mokhoa oa likoloi oa laser brazing oa 'mele

Ts'ebetso ea laser brazing e ipapisitse le molao-motheo o latelang: Ho sebelisa laser e le mohloli oa mocheso, lebone la laser le tsepamisitsoe 'me le khabisoa holim'a terata, terata ea qhibiliha, terata e qhibilihisitsoeng ea rothela fatše ebe e tlatsa sesebedisoa sa mosebetsi hore se chesetsoe, le liphello tsa metallurgical tse kang ho qhibiliha le ho hasana ho etsahala pakeng tsa lisebelisoa tsa brazing le workpiece, kahoo li kopanya workpiece. Ho fapana le ts'ebetso ea welding ea laser filler, mokhoa oa laser brazing o qhibilihisa terata feela eseng sesebelisoa se lokelang ho chesetsoa. Laser brazing e na le botsitso bo botle ba welding, empa matla a tsitsipano a sephetho sa weld a tlase. Setšoantšo sa 3 se bonts'a ts'ebeliso ea ts'ebetso ea laser brazing ho tjheseletsa sekoaelo sa phaposi ea mekotla ea likoloi

Ts'ebetsong ea ho cheselletsa 'mele oa koloi, mokhoa oa laser brazing o sebelisoa haholo ho tjheseletsa likarolo tsa' mele tse sa hlokeng matla a manonyeletso a phahameng, joalo ka ho cheselletsa lipakeng tsa sekoaelo se kaholimo le mahlakore a potolohileng, ho cheselletsa lipakeng tsa karolo e kaholimo le e tlase ea thoto. sekoaelo sa phaposi, joalo-joalo Sekoahelo se kaholimo sa VW, Audi le mefuta e meng ea mahareng le ea maemo a holimo kaofela li sebelisa mokhoa oa laser brazing.

Litšitiso tse kholo tsa manonyeletso a laser a 'mele ea koloi li kenyelletsa ho luma ka bohale, porosity, weld deformation, joalo-joalo, mme bofokoli bo ka hatelloa haholo ka ho laola liparamente tsa ts'ebetso le ho sebelisa mekhoa e mengata ea laser brazing.

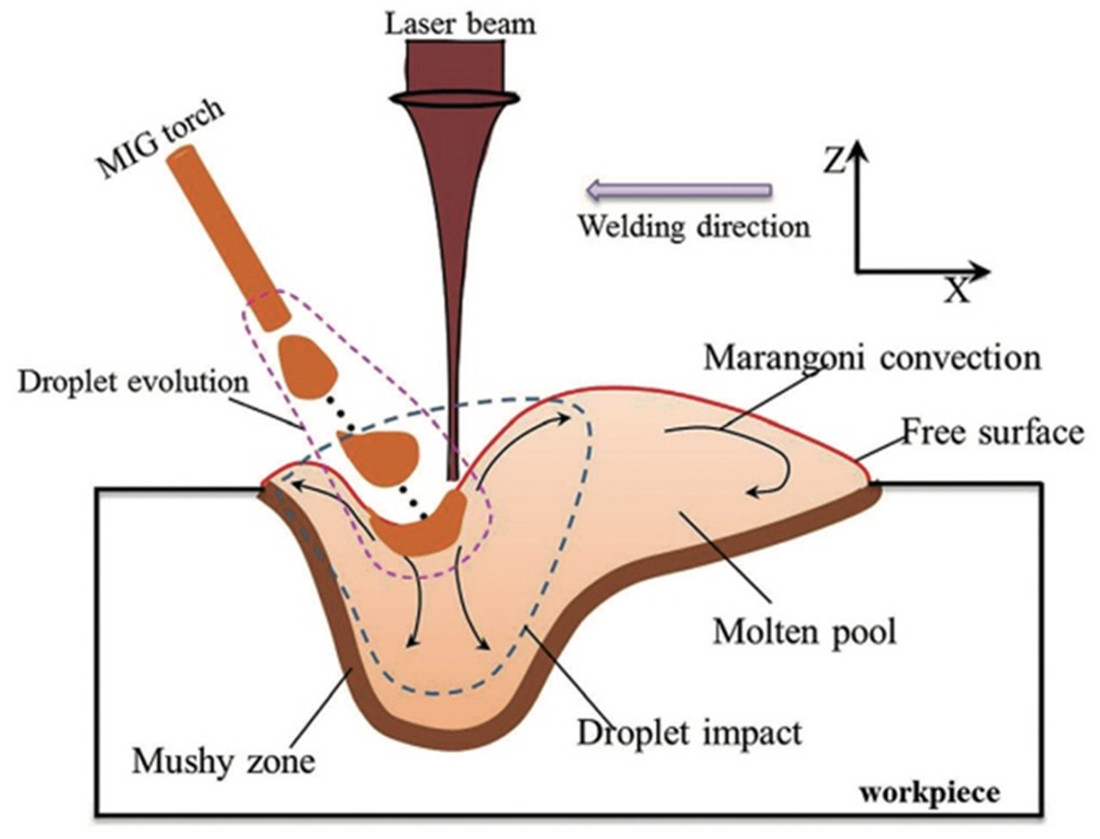

Mokhoa oa ho tjheseletsa oa 'mele oa koloi laser-arc composite

Molao-motheo oa laser-arc composite tjheseletsa tshebetso ke ka tsela e latelang: mehloli e 'meli ea mocheso, laser le arc, li sebelisetsoa ho sebetsa ka nako e le' ngoe holim'a workpiece ho tjheseletsa, 'me workpiece e qhibiliha ebe e tiisoa ho etsa seam ea weld. Setšoantšo se ka tlase se bonts'a ts'ebetso ea laser-arc welding.

Laser-arc composite welding e kopanya melemo ea laser welding le arc welding: pele, tlas'a ts'ebetso ea mehloli e 'meli ea mocheso, lebelo la welding le ka eketseha, mocheso oa mocheso o fetoha o monyenyane, deformation ea weld e nyenyane, e boloka litšobotsi tsa laser welding. ; ea bobeli, bokhoni bo betere ba ho koala, mamello ea lekhalo la kopano e kholoanyane; ea boraro, lebelo solidification ea letamo ho qhibilihisoa e ba butle, e leng loketseng ho felisoa ha pores, mapetsong le liphoso tse ling tjheseletsa, ho ntlafatsa mokhatlo o hlophisitsoeng le tshebetso ya libaka mocheso anngoeng ea bone, ka lebaka la ho arc, e khona ho tjheseletsa lisebelisoa tse nang le ponahalo e phahameng le conductivity e phahameng ea mocheso, e nang le mefuta e mengata ea lisebelisoa tse sebelisoang.

Ts'ebetsong ea tlhahiso ea 'mele oa likoloi, ts'ebetso ea welding ea laser - arc composite welding ke haholo-holo ho tjheseletsa likarolo tsa motsoako oa aluminium le motsoako oa aluminium - litšepe tse sa tšoaneng, bakeng sa lekhalo la kopano ea likarolo tse kholo tsa welding, joalo ka karolo ea monyako oa koloi ea sebaka. tjheseletsa, sena ke hobane lekhalo la kopano le loketse ts'ebetso ea borokho ea laser - arc composite bridging. Ho feta moo, theknoloji ea welding ea laser-MIG arc composite e boetse e sebelisoa sebakeng sa marulelo a mahlakoreng a marulelo a 'mele oa Audi.

Ts'ebetsong ea ho tjheseletsa 'mele oa koloi, welding ea laser-arc composite e na le monyetla oa mamello e kholo ea lekhalo ha e bapisoa le welding e le 'ngoe ea laser, leha ho le joalo, laser-arc composite welding e hloka ho nahanoa ka botlalo ka boemo bo amanang ba laser le arc, liparamente tsa welding tsa laser, arc. parameters le lintlha tse ling. Boitšoaro ba mocheso le boima ba ho tjheseletsa ha laser-arc bo rarahane, haholoholo taolo ya matla a heterogeneous material welding le mochine wa IMC botenya le taolo ya dinama e ntse e sa hlaka mme e hloka matlafatso e eketsehileng ya dipatlisiso.

Mekhoa e meng ea ho tjheseletsa ka laser 'mele ea likoloi

Laser deep fusion welding, laser filler welding, laser brazing le laser-arc composite welding le lits'ebetso tse ling tsa welding li na le mohopolo o holileng haholoanyane le mefuta e mengata ea lits'ebetso tse sebetsang. Ha litlhoko tsa indasteri ea likoloi bakeng sa ts'ebetso ea ho cheselletsa 'mele li ntse li eketseha le tlhokahalo ea ho cheselletsa lisebelisoa tse sa tšoaneng tlhahisong e bobebe e ntse e eketseha, laser spot welding, laser oscillation welding, multi-laser beam welding le laser flight welding li se li lebisitsoe tlhokomelong.

Mokhoa oa ho tjheseletsa letheba la laser

Laser spot welding ke theknoloji e tsoetseng pele ea welding ea laser e nang le melemo e ikhethang ea lebelo le potlakileng la welding le ho nepahala ho holimo. Molao-motheo oa ho tjheseletsa letheba la laser ke ho tsepamisa lebone la laser ntlheng ea karolo e lokelang ho chesetsoa, e le hore tšepe ka nako eo e qhibilihe hang-hang, 'me ka ho fetola sekhahla sa laser ho fihlella welding ea mocheso oa mocheso kapa phello e tebileng ea fusion, ha lebone la laser le emisa ho sebetsa, tšepe ea mokelikeli e fetoha, e tiisa 'me e theha lenonyeletso.

Ho na le mefuta e 'meli ea mantlha ea tjheseletsa letheba la laser: welding ea pulsed laser spot le welding e tsoelang pele ea laser spot. The laser beam in pulsed laser spot welding e na le matla a holimo, empa nako ea ts'ebetso e khuts'oane, 'me hangata e sebelisoa bakeng sa ho cheselletsa litšepe tse bobebe joalo ka lialloys tsa magnesium le lialloys tsa aluminium. Ka tjheseletsa ea letheba e tsoelang pele, lebone la laser le na le matla a mahareng le nako e telele ea ts'ebetso ea laser, 'me hangata le sebelisoa bakeng sa ho cheselletsa tšepe.

Ho tjheseletsa 'mele oa koloi, ha ho bapisoa le ho tjheseletsa letheba, laser spot welding e na le melemo ea ho tjheseletsa letheba ho sa kopane le ho iketsetsa sebaka, e ka fihlelang tlhokeho ea tjheseletsa ea boleng bo holimo tlas'a likheo tse fapaneng tsa lirope tsa thepa ea' mele ea koloi.

Laser oscillation tjheseletsa tshebetso

Laser oscillation welding ke thekenoloji e ncha ea laser welding e 'nileng ea sisinngoa lilemong tsa morao tjena' me e fumane tlhokomelo e pharaletseng. Molao-motheo oa theknoloji ena ke ho finyella oscillation e potlakileng, e hlophisehileng le e nyenyane ea lesela la laser ka ho kopanya seipone se oscillating ka hlooho ea laser welding, kahoo ho finyella phello ea ho sisinya sefate ha u ntse u tsoela pele nakong ea laser welding.

Litsela tse ka sehloohong tsa oscillation ts'ebetsong ea welding ea laser oscillation li kenyelletsa: oscillation transverse, longitudinal oscillation, circular oscillation le infinite oscillation. Ts'ebetso ea welding ea laser oscillation e na le melemo e mengata ea ho tjheseletsa 'mele oa koloi, kaha boemo ba phallo ea letamo le qhibilihang bo fetoha haholo ke oscillation ea lebone la laser, kahoo ts'ebetso e ka felisa mefokolo e sa keneng, ho fihlela ntlafatso ea lijo-thollo le ho hatella porosity ho tjheseletsa. thepa e tšoanang ea 'mele oa koloi, le ho ntlafatsa mathata a ho tsoaka ho sa lekaneng ha thepa e fapaneng le thepa e fosahetseng ea seam ea weld ho cheselletsa thepa ea 'mele e sa tšoaneng.

Multi-laser beam welding process

Hajoale, li-laser tsa fiber li ka sebelisoa ho arola seketsoana se le seng sa laser ho ba libalaka tse ngata tsa laser ho sebelisa mojule oa ho arola beam o kentsoeng hloohong ea welding. Multi-laser beam welding e lekana le ho sebelisa mehloli e mengata ea mocheso ts'ebetsong ea welding. Ka ho fetola kabo ea matla a sefate, maballo a fapaneng a ka finyella mesebetsi e sa tšoaneng, e kang: lebone le nang le matla a phahameng a matla ke lekhalo le ka sehloohong, le ikarabellang bakeng sa welding e tebileng ea ho qhibiliha; sub-beam e nang le matla a tlase a matla a matla a ka hloekisa le ho futhumatsa bokaholimo ba thepa le ho eketsa ho monya matla a beam ea laser ka thepa.

Ts'ebetso ea li-welding tsa laser tse ngata e ka ntlafatsa boitšoaro ba mouoane oa zinki le boits'oaro bo matla ba letamo le qhibilihang nakong ea ho tjheseletsa lishiti tsa tšepe tse entsoeng ka masenke, ho ntlafatsa bothata ba ho fafatsa le ho matlafatsa matla a tsitsitseng a seam sa weld.

Mokhoa oa ho tjheseletsa sefofane ka laser

Theknoloji ea ho tjheseletsa sefofane ka laser ke theknoloji e ncha ea welding ea laser e nang le ts'ebetso e phahameng ea welding le moralo o ikemetseng oa trajectory ea welding. Molao-motheo oa laser flight welding ke hore ha lebone la laser le etsahala liiponeng tsa X le Y tsa seipone sa ho hlahloba, angle ea seipone e laoloa ka mananeo a ikemetseng ho finyella ho kheloha ha lebone la laser ka tsela leha e le efe.

Ka tloaelo, laser welding ea 'mele oa koloi haholo-holo e itšetlehile ka roboto ea ho tjheseletsa ho khanna hlooho ea laser tjheseletsa bakeng sa motsamao oa synchronous ho fihlela phello ea welding. Leha ho le joalo, ho pheta-pheta ho pheta-pheta ha roboto ea ho cheselletsa ho fokotsa ka matla ho sebetsa hantle ha 'mele oa koloi ka lebaka la palo e kholo ea li-welds le bolelele bo bolelele ba li-welds. Ka lehlakoreng le leng, laser flight welding e ka finyelloa ka har'a mefuta e itseng ka ho fetola feela angle ea reflector. Ka hona, theknoloji ea welding ea sefofane sa laser e ka ntlafatsa haholo ts'ebetso ea tjheseletsa mme e na le tebello e pharaletseng ea ts'ebeliso.

Kakaretso

Ka nts'etsopele ea indasteri ea likoloi, bokamoso ba theknoloji ea ho cheselletsa 'mele e tla tsoela pele ho ntlafala ts'ebetsong ea welding le theknoloji e bohlale.

Auto body, haholo-holo 'mele o mocha oa koloi ea matla, o ntse o tsoela pele ho ea ka boima bo bobebe. Li-alloys tse bobebe, lisebelisoa tse kopaneng le lisebelisoa tse fapaneng li tla sebelisoa haholo 'meleng oa likoloi, ts'ebetso e tloaelehileng ea welding ea laser e thata ho fihlela litlhoko tsa eona tsa welding, ka hona, boleng bo holimo le ts'ebetso e sebetsang ea welding e tla fetoha mokhoa oa ntlafatso oa nako e tlang.

Lilemong tsa morao tjena, ts'ebetso ea welding ea laser e hlahang, joalo ka laser swing welding, multi-laser beam welding, laser flight welding, joalo-joalo, e bile boleng ba tjheseletsa le katleho ea tjheseletso ea lipatlisiso tsa pele tsa theory le tlhahlobo ea ts'ebetso. Bokamoso e lokela ho ba ts'ebetso e hlahang ea laser welding le lisebelisoa tse bobebe tsa 'mele, li-welding tse fapaneng tsa lisebelisoa le maemo a mang a kopantsoeng haufi-ufi, moralo oa laser beam swing trajectory, mochini o sebetsang oa matla a laser a mangata le ntlafatso ea ts'ebetso ea ho tjheseletsa sefofaneng le likarolo tse ling tsa ho lipatlisiso tse tebileng ho hlahloba ts'ebetso ea ho cheselletsa 'mele e bobebe e bobebe.

Theknoloji ea auto body laser welding e ntse e hokahanngoa ka botebo le thekenoloji e bohlale, ho lemoha ka nako ea 'nete boemo ba auto body laser welding le taolo ea maikutlo ea likarolo tsa ts'ebetso li na le karolo ea bohlokoa ho boleng ba tjheseletsa. Theknoloji ea morao-rao e bohlale ea welding ea laser e sebelisoa haholo bakeng sa moralo oa pele oa welding trajectory le ho latedisa le ho hlahloba boleng ba kamora ho tjheseletsa. Patlisiso ea lehae le kantle ho naha mabapi le ho lemoha mefokolo ea li-welding le taolo e feto-fetohang ea li-parameter e ntse e le qalong, 'me theknoloji ea taolo ea "laser welding" ha e so sebelisoe indastering ea likoloi.

Ka hona, bakeng sa ts'ebeliso ea theknoloji ea ho tjheseletsa ka laser ho litšoaneleho tsa ts'ebetso ea 'mele oa koloi, bokamoso bo lokela ho ntlafatsoa ka mokhoa o tsoetseng pele oa li-multi-sensor core laser welding smart sensing system le sistimi ea taolo ea liroboto tse nepahetseng ka lebelo le holimo ho netefatsa hore tjheseletsa ea laser. bohlale thekenoloji ka nako ea sebele le ho nepahala ha kgokahanyo e 'ngoe le e' ngoe, ka "pre-welding trajectory planning - welding parameters adaptive control post-welding quality online Inspection" link, ho netefatsa boleng bo phahameng le ho sebetsa hantle.

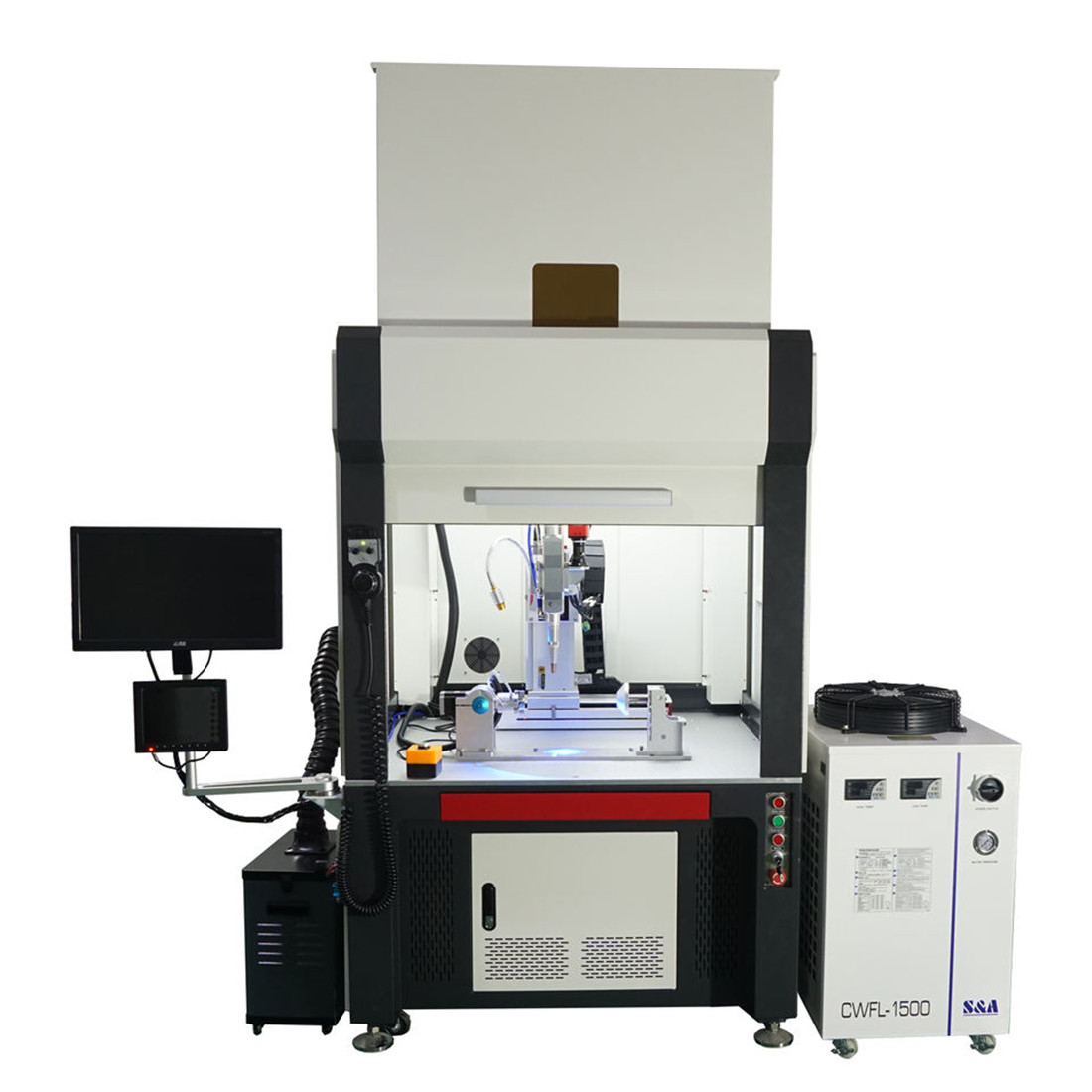

Khamphani ea Maven laser automation e tsepamisitse maikutlo indastering ea laser ka lilemo tse 14, re sebetsa ka thata ho tjheseletsa laser, re na le mochini oa welding oa letsoho oa robotiki, mochini oa welding oa Table Automatic Laser Welding, Handheld Laser welding mochini, ho feta moo, re boetse re na le mochini oa welding oa laser, mochini o sehang oa laser. le laser ho tšoaea mochini oa ho ngola, re na le linyeoe tse ngata tsa tharollo ea welding ea laser, haeba u thahasella u ka ikopanya le rona kamehla.

Nako ea poso: Dec-09-2022