Mochini o Tsoelang Pele oa Fiber Laser Welding Bakeng saPillow Plate Heat Transfer Plate.

Lefatšeng le ntseng le tsoela pele la tlhahiso ea indasteri, tlhokahalo ea mekhoa e sebetsang hantle, ea boleng bo phahameng ha e e-s'o ka e e-ba kholoanyane.

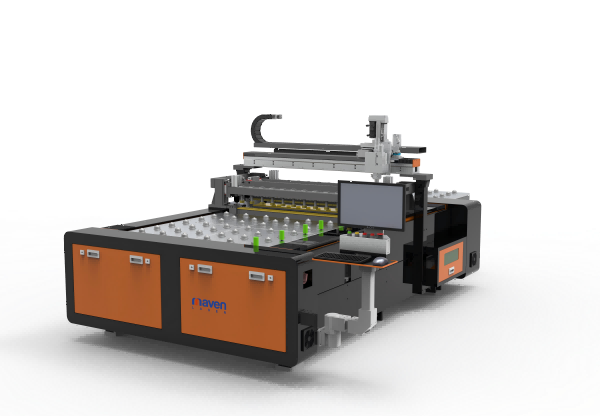

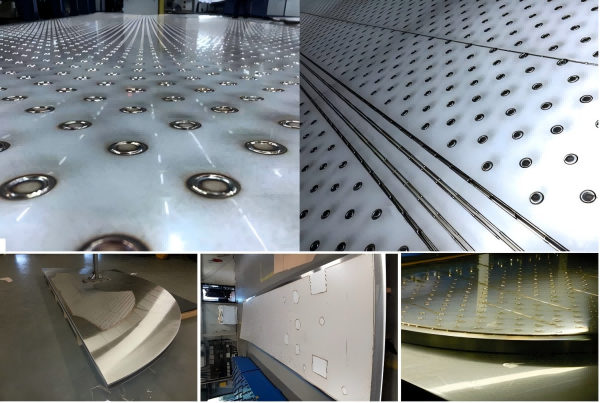

E 'ngoe ea tsoelo-pele e ncha ka ho fetisisa lefapheng lena ke mochine o tsoelang pele oa fiber laser welding, haholo-holo ha o sebelisoa ho hlahisa lipoleiti tsa ho fetisa mocheso oa pillow plate.

Motsoako ona oa theknoloji le moralo o fetola tsela eo indasteri e amohelang tharollo ea ho fetisa mocheso.

Ithute ka pillow plate e fetisang mocheso

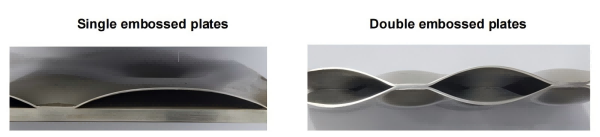

Lipoleiti tse fetisang mocheso oa pillow plate ke mochine o tloaelehileng oa mocheso o sebelisoang lits'ebetsong tse kang air conditioning, lisebelisoa tsa sehatsetsing le litora tsa ho pholisa.

Molao-motheo oa eona oa ho sebetsa ke ho sebelisa mokhoa oa ho phalla ha mekhahlelo e 'meli le molao-motheo oa ho fetisa mocheso ho fetisetsa mocheso.

Letlapa la condensing le na le letoto lalipoleiti tsa tšepe tse bapileng.Lehlakore le le leng la poleiti le sebelisetsoa ho fetisetsa palo ea moemeli oa condensing, e bitsoang lehlakoreng le chesang;Lehlakore le leng la poleiti le sebelisetsoa ho fetisetsa mocheso oa thepa e pholileng, e bitsoang lehlakoreng le batang.

Karolo ea ho tjheseletsa ha fiber laser e tsoelang pele

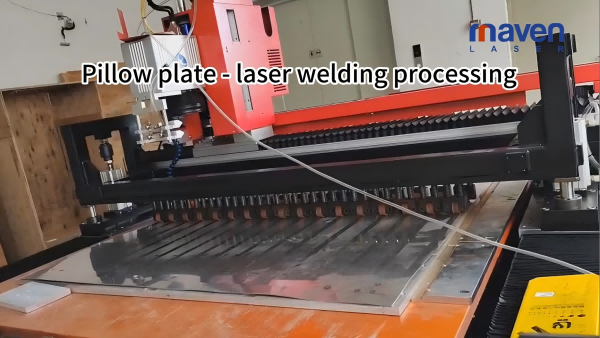

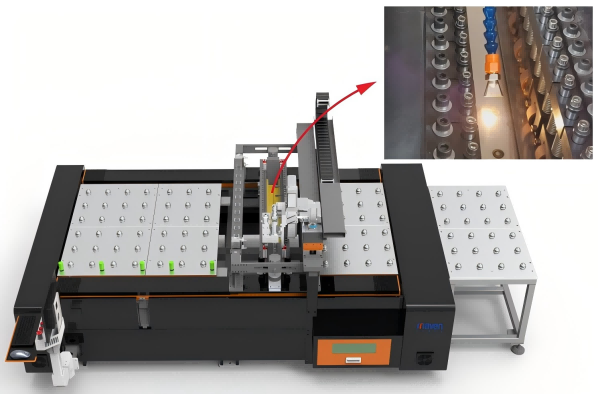

Mochini o tsoelang pele oa fiber laser welding o bapala karolo ea bohlokoa tlhahisong ea lipoleiti tse fetisang mocheso. Theknoloji ena e tsoetseng pele ea ho tjheseletsa e sebelisa lebone le tsoelang pele la fiber laser ho etsa li-welds tse nepahetseng le tse matla. Ha ho bapisoa le mekhoa ea khale ea ho tjheseletsa, e jang nako mme e ka senya botshepehi ba thepa, fiber laser welding e na le melemo e mengata:

1) Ho nepahala le Boleng: Maballo a laser a matla a phahameng a thusa ho cheselletsa ka nepo, ho netefatsa hore moralo o rarahaneng oa bolster o lula o tiile.

Ho nepahala hona ho bohlokoa ho fihlela katleho e nepahetseng ea ho fetisa mocheso.

2) Lebelo le Katleho: Tšebeliso e tsoelang pele ea fiber laser e potlakile haholo ho feta mekhoa ea khale ea welding. Lebelo lena ha le eketse tlhahiso feela empa hape le fokotsa litšenyehelo tsa ts'ebetso, ho etsa hore e be khetho e khahlehang bakeng sa bahlahisi.

3) Sebaka se Ametsoeng ke Mocheso o fokolang: Litšobotsi tse tsepamisitsoeng tsa laser li fokotsa sebaka se amehileng ke mocheso, ka hona li fokotsa kotsi ea deformation kapa tšenyo ea thepa e potolohileng.

Thepa ena e bohlokoa ka ho khetheha tlhahisong ea lipoleiti tsa ho fetisa mocheso, moo botšepehi ba thepa bo leng bohlokoa.

4) Ho feto-fetoha ha maemo: Mechini e tsoelang pele ea fiber laser welding e ka tjheseletsa lisebelisoa tse fapaneng, ho kenyeletsoa tšepe e sa hloekang le aluminium, tseo hangata li sebelisetsoang lipoleiti tse fetisang mocheso oa pillow plate.

Mokhoa ona o fapaneng o lumella bahlahisi ho ikamahanya le litlhoko tse fapaneng tsa projeke ntle le ho tsetela lits'ebetsong tse ngata tsa welding.

Kopo ea indasteri

Ho kopanngoa ha mechine e tsoelang pele ea ho tjheseletsa ha fiber laser ha ho etsoa lipoleiti tsa ho fetisa mocheso oa pillow plate ho bile le phello e tebileng liindastering tse sa tšoaneng.

Mohlala, indastering ea lijo le lino, lipoleiti tsena li bohlokoa haholo bakeng sa pasteurization le lits'ebetso tsa ho pholisa, tseo ts'ebetso le bohloeki li leng bohlokoa ho tsona. Ka indasteri ea lik'hemik'hale li sebelisoa ho li-reactors le mocheso oa mocheso moo ts'ebetso e ka tšeptjoang e ke keng ea hlokomolohuoa.

Ho feta moo, indasteri ea HVAC e rua molemo ho thepa e ntlafalitsoeng ea mocheso oa liphanele tsa mesamo, e lumellang hore ho be le lisebelisoa tse sebetsang hantle tsa ho futhumatsa le ho pholisa. Ha liindasteri li ntse li tsepamisa maikutlo ho ts'ebetsong, bokhoni ba ho hlahisa litharollo tsa boleng bo phahameng ba ho fetisa mocheso le ho fokotsa tšebeliso ea matla e fetoha monyetla o moholo oa tlhōlisano.

Mohlala o Mong

Ha re phethela

Mechini e tsoelang pele ea fiber laser welding e emela tsoelo-pele e kholo molemong oa tlhahiso ea poleiti ea ho fetisa mocheso.

Ka ho kopanya ho nepahala, lebelo le ho feto-fetoha ha maemo, theknoloji ha e ntlafatse feela boleng ba sehlahisoa sa ho qetela empa hape e thusa ho ntlafatsa katleho ea kakaretso ea mekhoa ea indasteri. Ha liindasteri li ntse li tsoela pele ho batla litharollo tse ncha tsa ho khotsofatsa litlhoko tsa tsona tsa ho fetisa mocheso, tšebelisano lipakeng tsa fiber laser welding le theknoloji ea bolster e tla phetha karolo ea bohlokoa ho bopeng bokamoso ba tlhahiso.

Nako ea poso: Oct-17-2024