Mochini oa Welding oa Laser Bakeng sa Mabenyane a Tšepe a nang le Portable Pulse Welder

Laser letheba mochini tjheseletsa bakeng sa mabenyane a haholo-holo sebelisoa ho tlatsa masoba le letheba weld trachoma ea khauta le silevera mabenyane, laser letheba tjheseletsa ke e 'ngoe ea likarolo tsa bohlokoa tsa dikopo laser thepa sebetsa theknoloji, letheba tshebetso tjheseletsa ke mocheso conduction mofuta, ke hore, laser. mahlaseli futhumatsang holim'a workpiece, mocheso holim'a mocheso conduction mocheso ho diffusion ka hare, ka ho laola tham mong bang laser pulse bophara, matla, tlhōrō matla le ho pheta-pheta maqhubu le mekhahlelo e meng, e le hore workpiece qhibiliha, ho etsa e itseng qhibiliha letamo. Ka lebaka la melemo ea eona e ikhethang, e sebelisitsoe ka katleho ho sebetsa mabenyane a khauta le silevera le welding ea likarolo tse nyane le tse nyane.

Melemo

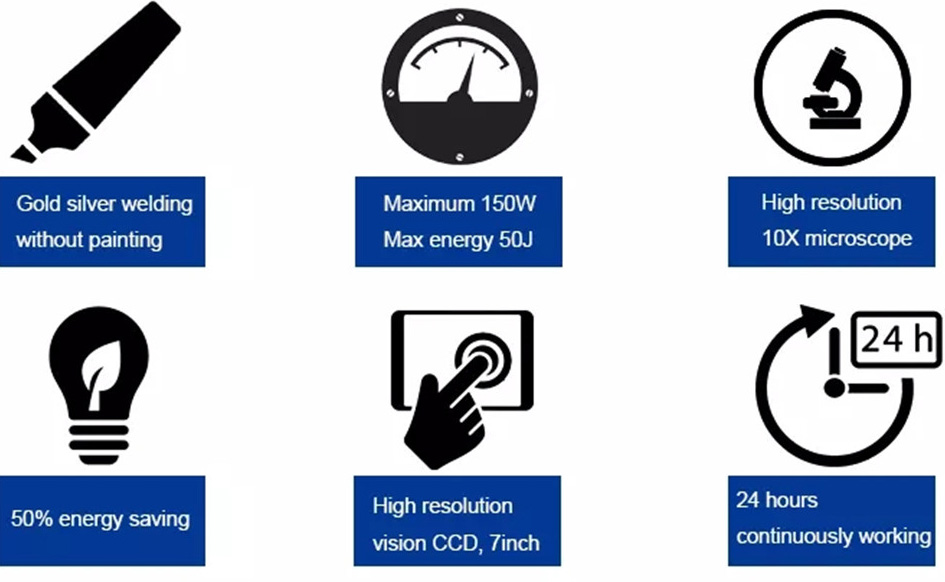

1.Khauta e hloekileng le silevera li ne li ka pheta-pheta ho tjheseletsa ntle le ho penta

2.Botebo bo Phahameng ba Tšimo ea Maikutlo le Tlhaloso e Phahameng

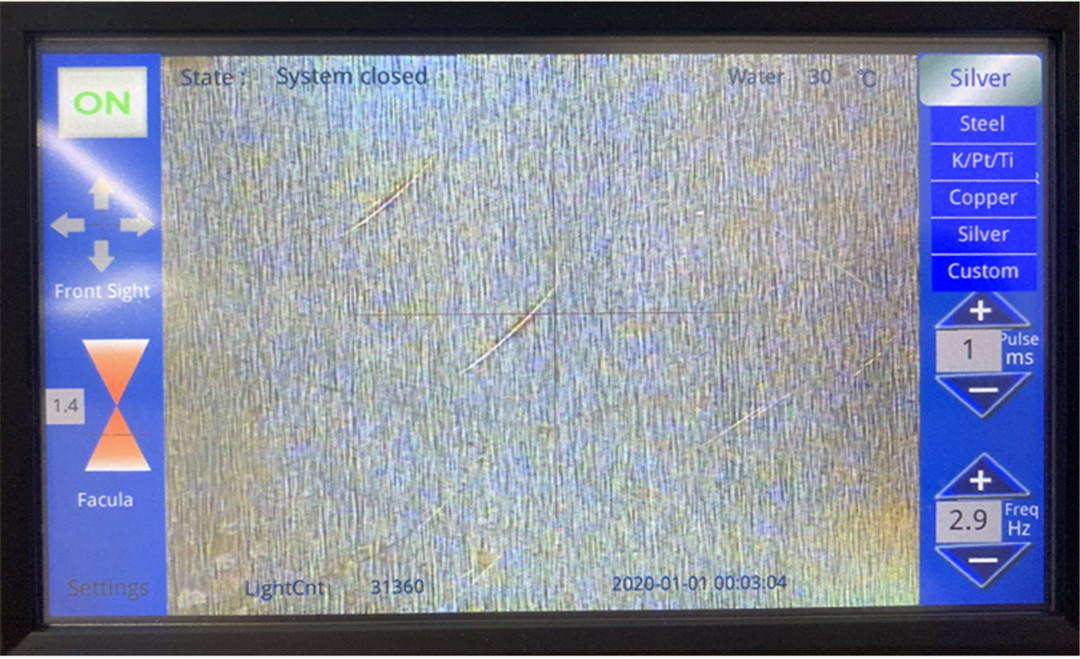

3.Tsehetsa ka bobeli CCD le microscope

4.Pulse Wave Shape e nang le li-presets tse 8, e betere bakeng sa lisebelisoa tse fapaneng tsa welding

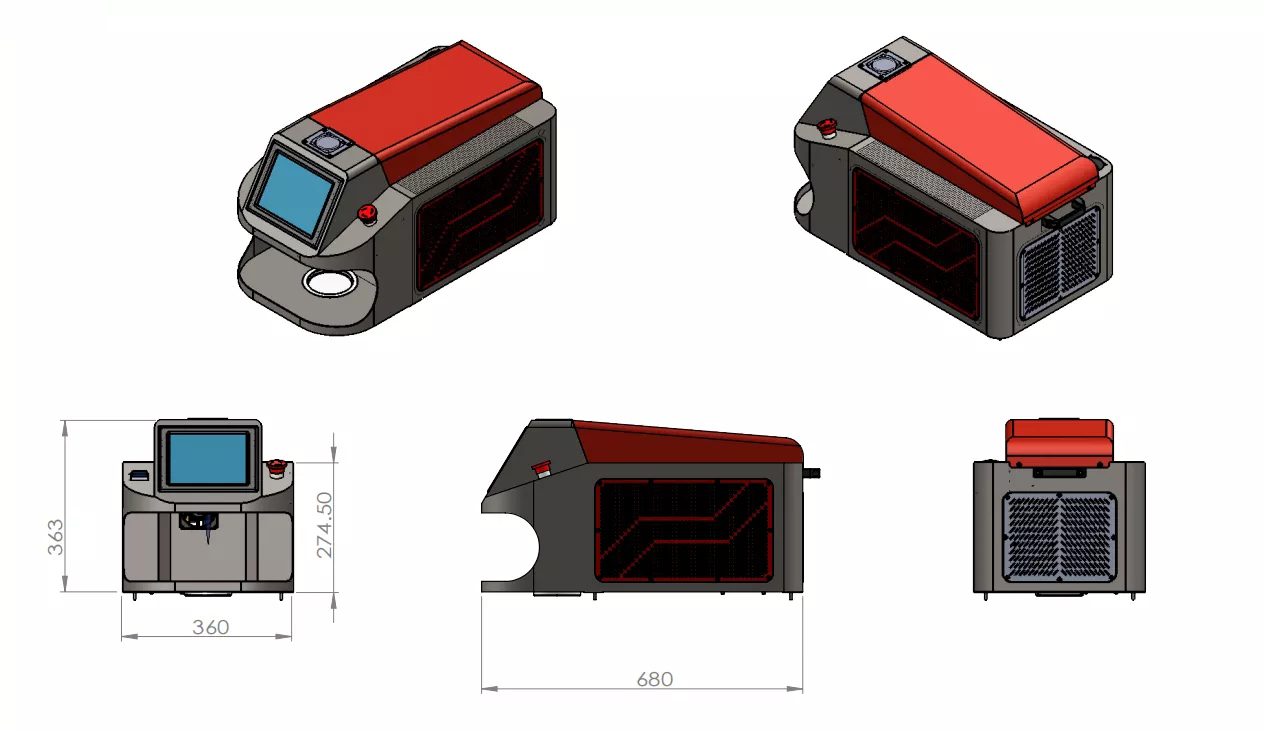

Likarolo tsa mochini oa welding laser spot welding:

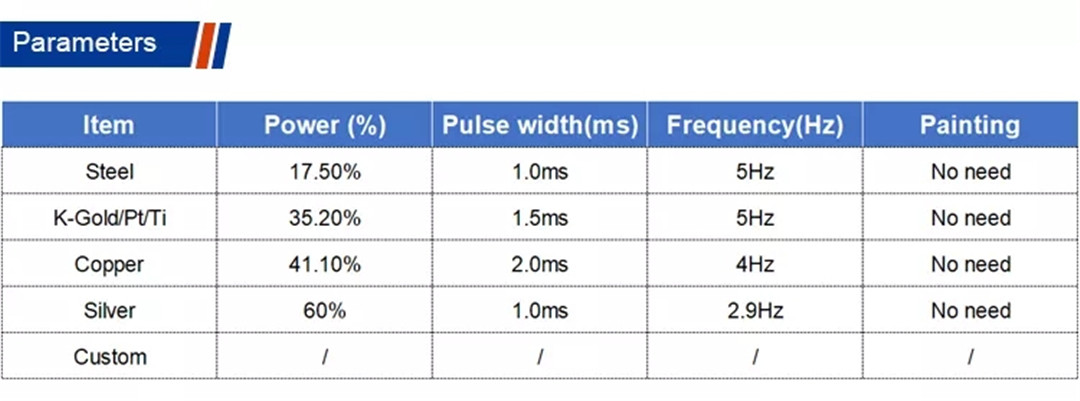

Matla, bophara ba pulse, frequency le boholo ba matheba bo ka fetoloa ka mefuta e mengata ho fihlela litlamorao tse fapaneng tsa welding. Mekhahlelo e lokisoa ke lever ea taolo sebakeng se koetsoeng, se bonolo le se sebetsang hantle.

Amohela sisteme e tsoetseng pele ea shading ho felisa ts'usumetso ea mahlo nakong ea lihora tsa mosebetsi.

Ka bokhoni ba ho sebetsa bo tsoelang pele ba lihora tse 24, mochini oohle o na le ts'ebetso e tsitsitseng mme ha o lokisoe nakong ea lihora tse 10000.

Moralo oa batho, ergonomic, ha ho mokhathala ka lihora tse telele tsa ho sebetsa.

Melemo ea mochine oa ho roala mabenyane a laser: lebelo le potlakileng, ts'ebetso e phahameng, botebo bo boholo, ho senyeha ho honyenyane, sebaka se senyenyane se amehileng ke mocheso, boleng bo phahameng ba ho tjheseletsa, manonyeletso a se nang tšilafalo, bokhoni bo phahameng le tšireletso ea tikoloho.

Likaroloana

1. Khokahano, sistimi e pholileng ea moea e hahelletsoeng ka har'a moea, mochini o futhumatsang habeli, Tšebeliso ea matla le ho boloka sebaka..

2. Bohlale: taolo ea othomathike ea hona joale e koetsoeng, phetoho ea lebelo la moea ka boiketsetso, ts'ireletso ea maemo a mangata, ho nepahala le botsitso..

3. Mokhoa o bohlale oa ho laola lipuo tse ngata, taolo e kopanetsoeng le ho shebella, ho bonolo ho sebetsa, koetliso ea metsotso ea 5 e ka laola mochine.

4. Motlakase o mocha o khethehileng oa patent laser cavity le optical circuit, bokhoni bo phahameng ba electro-optic, phetoho, tlhokomelo e bonolo, ho nkela lebone la xenon sebaka.

| Mohlala No. | MLA-W-A14 |

| Lebitso la Sehlahiswa | YAG Jewelry Laser Welding Machine |

| Mohloli oa Laser ND | YAG |

| Wavelength | 1064nm |

| Matla a Matla | 160W |

| Khafetsa | 0.1-30HZ |

| Pulse Width | 0.1-20ms |

| Beam Diameter Adjustment Range | 0.3-2 limilimithara |

| Matla ka Motsotsoana | 100J |

| Sepheo sa Boemo | Ka bobeli li tšehetsa CCD le microscope |

| CCD Touch Screen | 8 inch, 10X tlhaloso e phahameng |

| Boemo bo Nepahetseng | +/-0.02mm |

| Memori File | 100 kapa hlalosa |

| Mananeo a Leqhubu | Pulse shaping 8 presets |

| Ho phodisa | Pholiso e bohlale habeli ka ho pholisa metsi le moea o pholileng |

| Argon Air nozzle | E tšehelitsoe |

| Phepelo ea motlakase | 220V/50Hz/30A |

MavenLaser Daily Packing Details

Ka kakaretsoMekhahlelo e 3 ea ho paka ka hare

Methati ea 1: 9+ lifilimi tse sireletsang

Methati ea 2: 1+ K'hothone ea foam ea 3.0+mm

Mothati oa 3: 9+lifilimi tse sireletsang

Ho paka ka hare NW: 1-5 kg

- Kereiti ea lehong e nang le lipekere

- (Haeba bareki ba hloka)

-

Kereiti ea lehong e nang le linotlolo tsa tšepe

- (Ka kakaretso ea paka)

Kereiti ea lehong e sa cheseheng e nang le pampiri ea tšepe e phuthetsoeng

Lebokose la Carton (Le ka buisanoa)

LBH

Q1: Ha ke tsebe letho ka mochine ona, ke mofuta ofe oa mochine oo ke lokelang ho o khetha?

Re tla u thusa ho khetha mochine o loketseng le ho arolelana le uena tharollo ea rona e molemohali;

U ka re arolelana hore na u tla tšoaea/ u tla ngola mongolo oa mofuta ofe.

Q2: Ha ke fumana mochine ona, empa ha ke tsebe ho o sebelisa. Ke etseng?

Re ka romella video ea ts'ebetso le bukana ea mochini bakeng sa mochini. Moenjiniere oa rona o tla etsa koetliso inthaneteng.

Haeba ho hlokahala, re ka romella moenjiniere oa rona sebakeng sa hau sa marang-rang bakeng sa koetliso kapa o ka romella opereishene fekthering ea rona bakeng sa koetliso.

Q3: Haeba mathata a mang a hlahela mochine ona, ke lokela ho etsa eng?

Re fana ka tiisetso e felletseng ea mochini oa lilemo tse peli.

Mathata leha e le afe a etsahetse tlas'a tiisetso, likarolo li tla fanoa bakeng sa ho nkela sebaka kapa ho lokisoa mahala.

Haeba ho feta waranti, re ntse re fana ka litšebeletso tse ntle haholo.