Mochini oa Welding oa Yag Spot Laser Welding

Mochini oa Welding oa Laser oa Yag Laser

LIKAROLOANA

-Khauta le silevera ho lokisa welding ntle le ho penta

-Boholo ba 230W, 90Joule

-50% ea ho boloka matla

-Boemo bo phahameng ba pono CCD, 7inch

-Lihora tse 24 li sebetsa ka thata

Tšireletseho e ntle: ka sesebelisoa sa ts'ireletso ea leseli la elektronike le lebelo le phahameng ho sireletsa mahlo a opereishene ho senyeha ha laser, ho imolla mokhathala oa mahlo a opereishene le ho ntlafatsa katleho ea mosebetsi.

Bokhoni bo matla ba ho thibela tšitiso: Tšebeliso ea k'homphieutha e tsoetseng pele ea theknoloji e ncha ea liindasteri tse nyenyane, ho e-na le ts'ebetso e feletseng ea lik'homphieutha tse tloaelehileng, ho sebetsa ha eona le botsitso ho ea boemong bo phahameng, le ho tsamaisana le linako.

Botsitso bo phahameng: ts'ebeliso ea taolo e nepahetseng ea li-loop tse peli tse koetsoeng, ho etsa bonnete ba hore matla a ntlha e 'ngoe le e' ngoe ea welding e tšoana ebile e tsitsitse.

Ts'ebetso e bonolo le e bonolo: ka pono e kholo ea skrine e phahameng ea CCD, litlhophiso tsa parameter ea Senyesemane li bonolo ho li utloisisa, li ka boloka mekhoa e mengata ho tsamaisa mosebetsi o tsoelang pele.

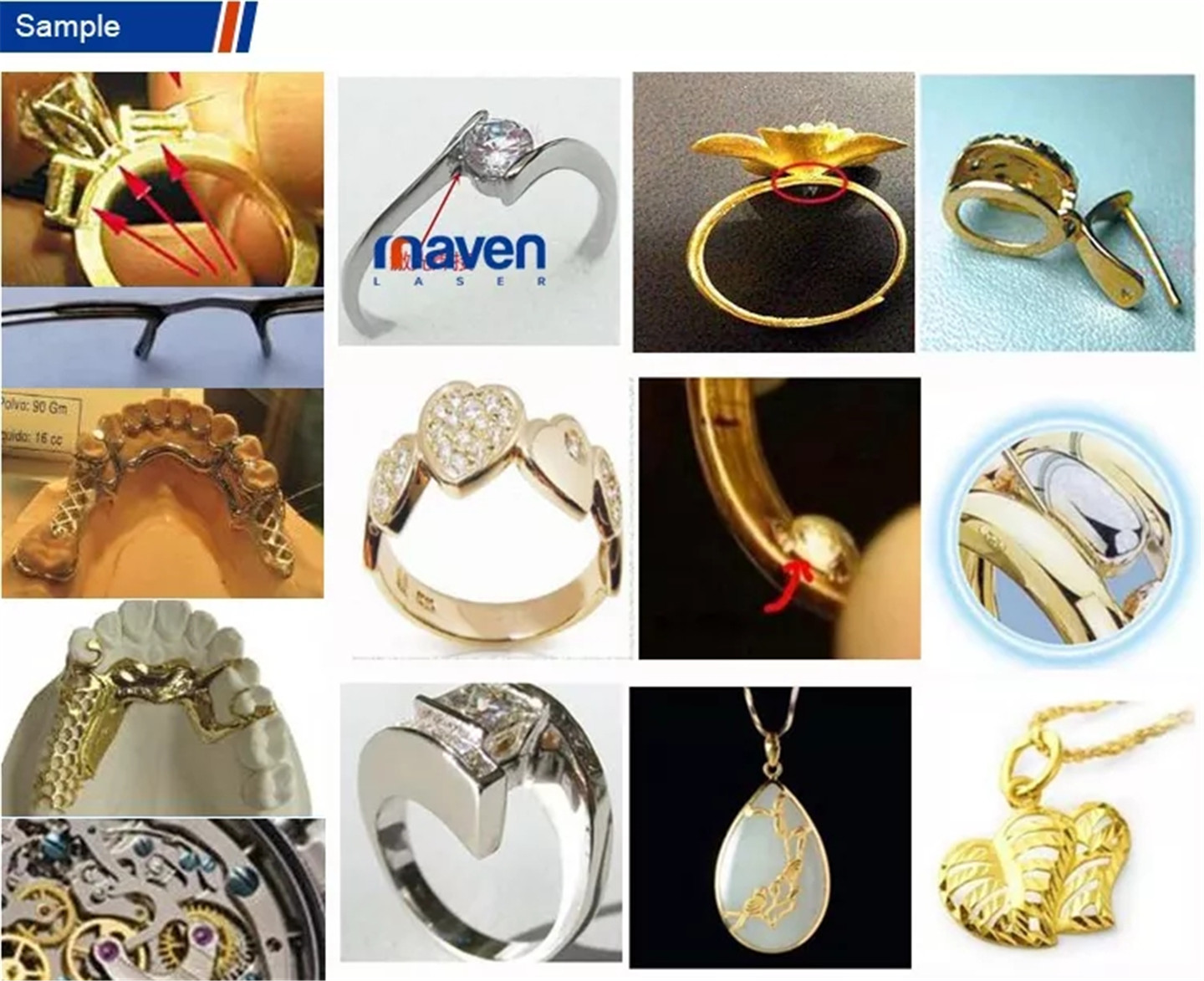

Laser spot weldere sebelisoa haholo indastering ea mabenyane le ea meno kapa masimong a mang a Hardware. Mofuta onamochini o ka sebetsana le lisebelisoa tsohle tsa tšepe, tse neng li sebelisetsoa ho etsa mabenyane a kang khauta,silevera, platinum, titanium, palladium, K-Gold, Stainless steel, le metsoako ea tsona. E sebelisoa haholo-holo bakeng saho etsa le ho lokisa mabenyane, hammoho le ho cheselletsa mefuta e fapaneng ea li-micro le mocheso-likarolo tse mahlonoko, joalo ka marapo a nickel a libeteri, lithapo tsa moriri, likarolo tsa oache, tse ka tlase tsali-chips.

Melemo ea Sehlahisoa

Ka kakaretso CCDmochini oa ho roala mabenyane oa laser

2. Focus letheba fetola karolo

3. Preset laser welding parameters. Ho kenyeletsoa khauta, silevera, tšepe, titanium le tloaelo.

4. Sebaka sa boitsebiso ba boemo

5. Matla, bophara ba pulse le frequency fetola karolo

6. Ho beha

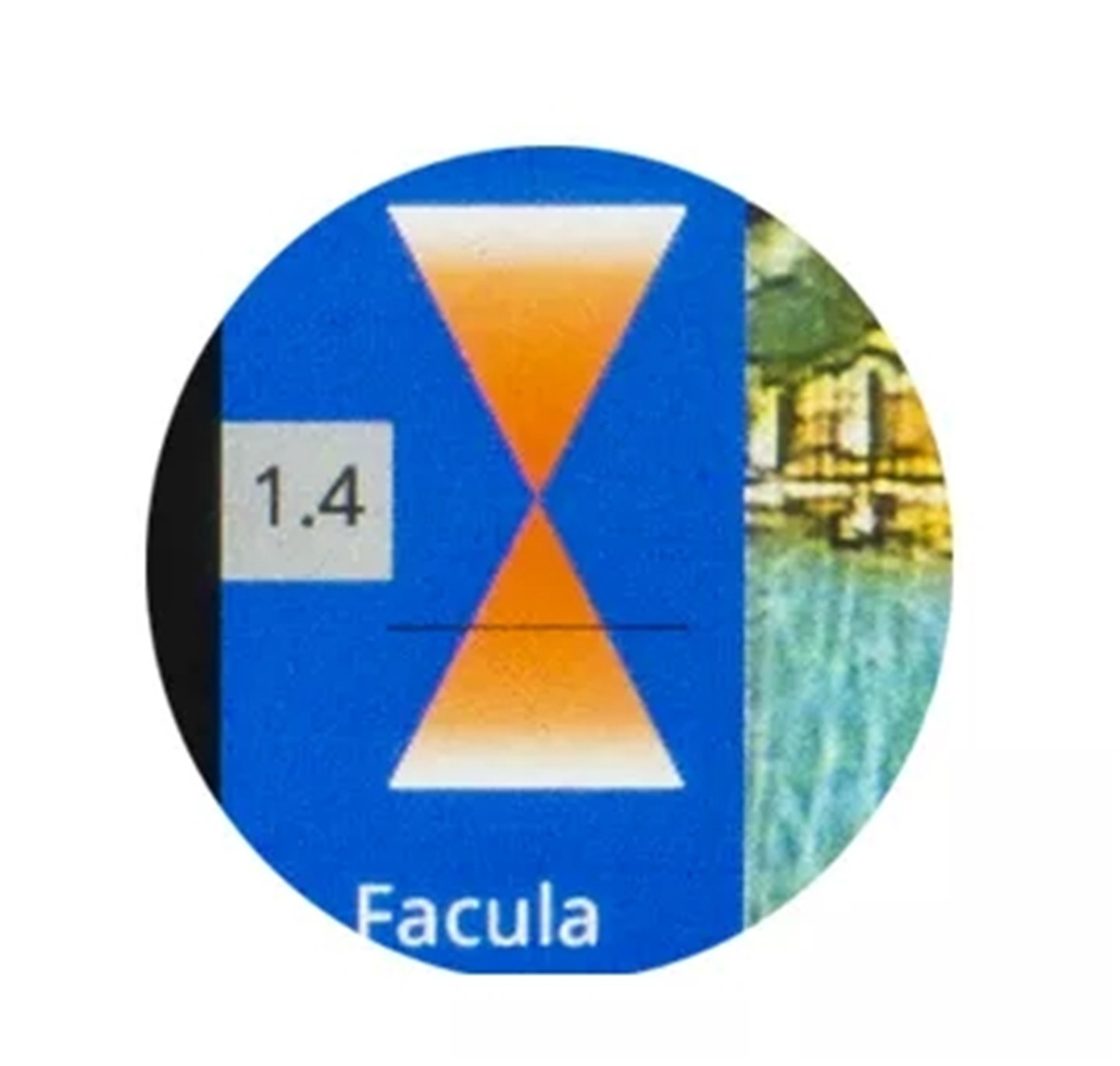

Tokiso ea boholo ba letheba

Litlhophiso tsa litokiso tse bonolo ho basebelisi, ho tloha ho -3.0mm ho isa ho 3mm.

Spot size ho minus direction, e loketse ho feta bakeng sa ho tjheseletsa post treatment welding le welding e tshesane ya kgauta le silifera lakane e lokisang tjheseletsa.

Ha e ntse e le ka lehlakoreng le leng, e loketse haholoanyane bakeng sa welding ea laser e tebileng

Focus cross line adjust center

Position of focus cross line e ka fetoloa habonolo ka karolo ena

Seta pele parameter le ho lokisa

Perst laser welding paramter ke tlhahiso ea rona, ho kenyelletsa K-Gold/Pt/Ti, silevera, tšepe, koporo le tloaelo.

Matla a Laser: 0.1% ~ 100%

Pulse bophara: 0.1ms ~ 20ms

Khafetsa: 1Hz ~ 50Hz

Tsela ea patent

Tsela ea patent ea patent le moralo o felletseng oa mochini o etsa hore Mavenlaser e be ea k'hamphanimochini oa ho roala mabenyane a lasere ikhethang ebile e phethahetse, eseng ka ts'ebetso kapa ka boholo.

Kamore ea ho tjheseletsa laser

1. Nozzle ea moea

2. Konopo ea tshohanyetso

3. Boleng bo phahameng bo mosehla bo bobebe

4. High quality White lighter

5. Spot manual e nepahetseng lebili

6. Joystick

| Ntho | Matla (%) | Pulse width(ms) | Hangata(Hz) | Ho penta |

| Tšepe | 17.5% | 1.0ms | 5Hz | Ha ho hlokahale |

| K-Gold/Pt/Ti | 35.2% | 1.5ms | 5Hz | Ha ho hlokahale |

| Koporo | 41.1% | 2.0ms | 4Hz | Ha ho hlokahale |

| Silevera | 60% | 1.0ms | 2.9Hz | Ha ho hlokahale |

| Tloaelo | / | / | / | / |

Tlhaloso

| Lebitso la sehlahisoa | Mochini oa ho roala mabenyane oa laser |

| Mohloli oa laser | Nd: YAG 1064nm |

| Mohlala No. | MLA-W-A01 |

| Matla a phahameng a laser | 230W |

| Sebaka sa maqhubu | 1-50Hz |

| Pulse bophara bo fapaneng | 1 ~ 20ms |

| Sebaka sa boholo ba sebaka | -3 limilimithara ~ 3 limilimithara |

| Tšusumetso ea matla le nako | 140J @20ms |

| Ho beha sepheo | CCD, microscope ea 10X |

| Ho beha ho nepahala | +/-0.02mm |

| Matla a kenyang | 220V 50/60Hz 30A |

| Boholo ba mochini | 790*390*1090mm |

Mohlala & Sesebelisoa