Mochini o Tletseng oa Handheld Fiber Handheld Laser Welding Machine

Tlhaloso ea Sehlahisoa

Handheld laser welding mochini lipheo tsa setsebi tsa tlhahiso, o na le maemo a holimo a melemo ea indasteri ea profeshenale, ha o ntse o netefatsa ho ts'oaroa ha lipheo tse nepahetseng ho netefatsa ts'ebetso, empa hape le ho fihlela moralo o sebetsang le o sebetsang oa botho.

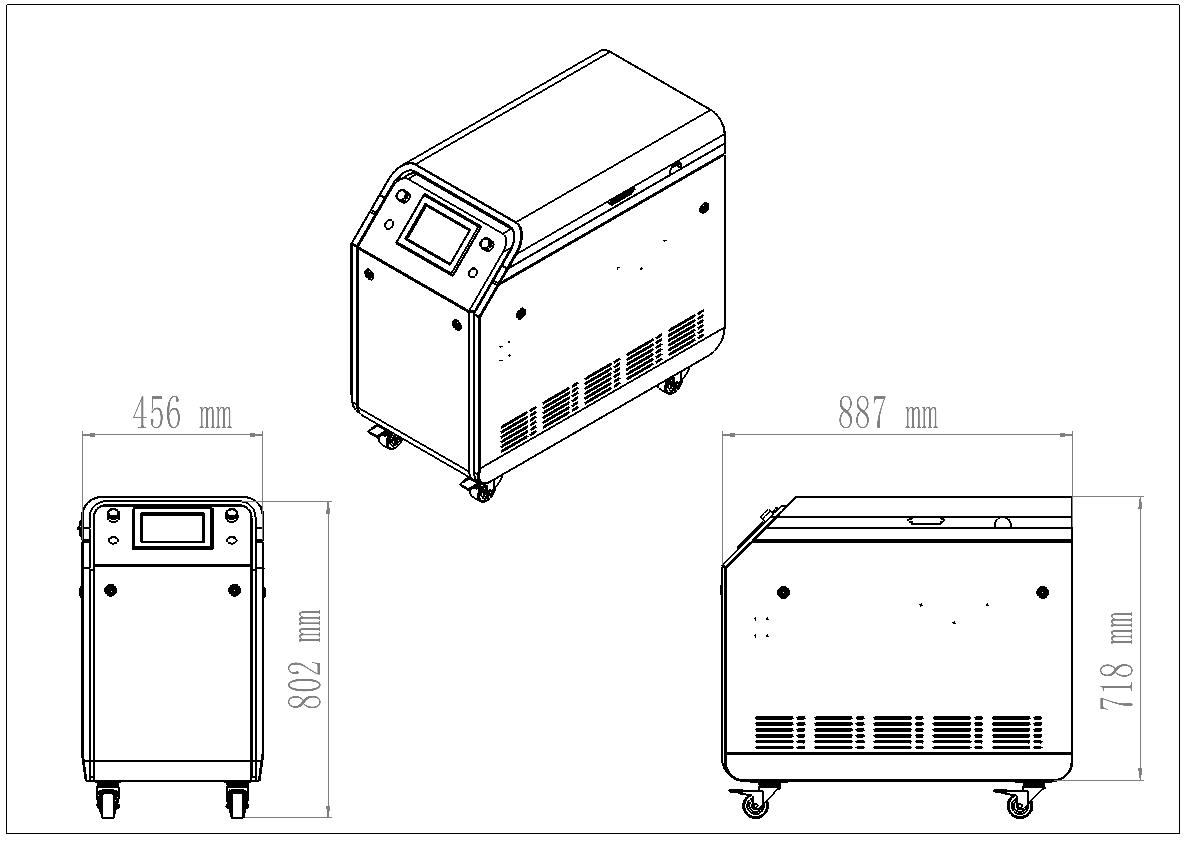

| Boholo ba Mochini: | |

| Bolelele | 456 limilimithara |

| bophara | 887 limilimithara |

| Bophahamo | 718 limilimithara |

| 1.Khabinete e nyane ebile e ntle haholo2. Ka pulley e boreleli ea silky 3. Khabinete e tšoeu E nang le sekoaelo se holimo | |

Likarolo le melemo ea mochini oa welding oa laser o tšoaroang ka letsoho:

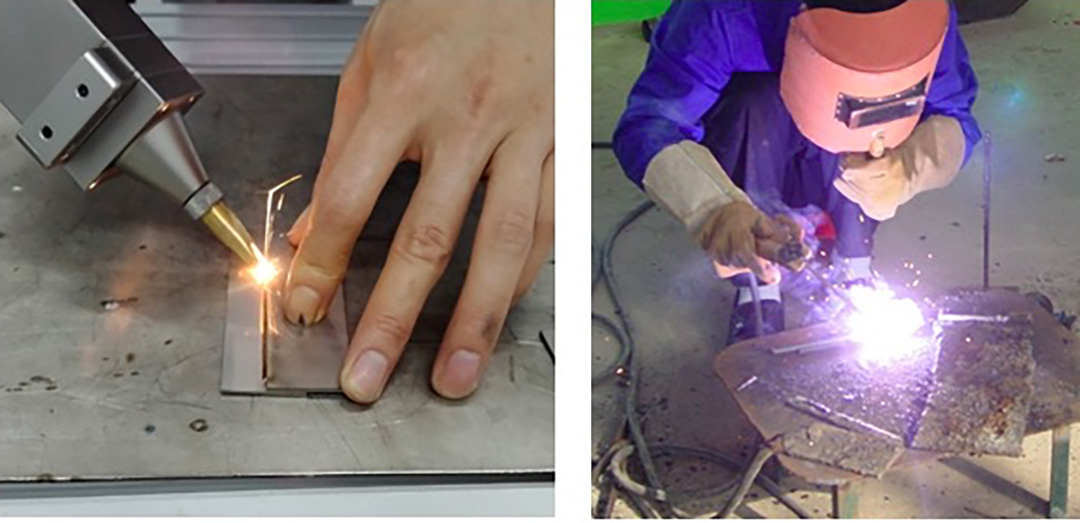

handheld laser tjheseletsa mochini tjheseletsa sethunya sebakeng sa setso e tsitsitseng optical tsela, ho feta tenyetseha le loketseng ho finyella sebaka se selelele ka laser tjheseletsa, ho hlōla mefokolo ea sebaka sa ho tsamaea tafoleng;

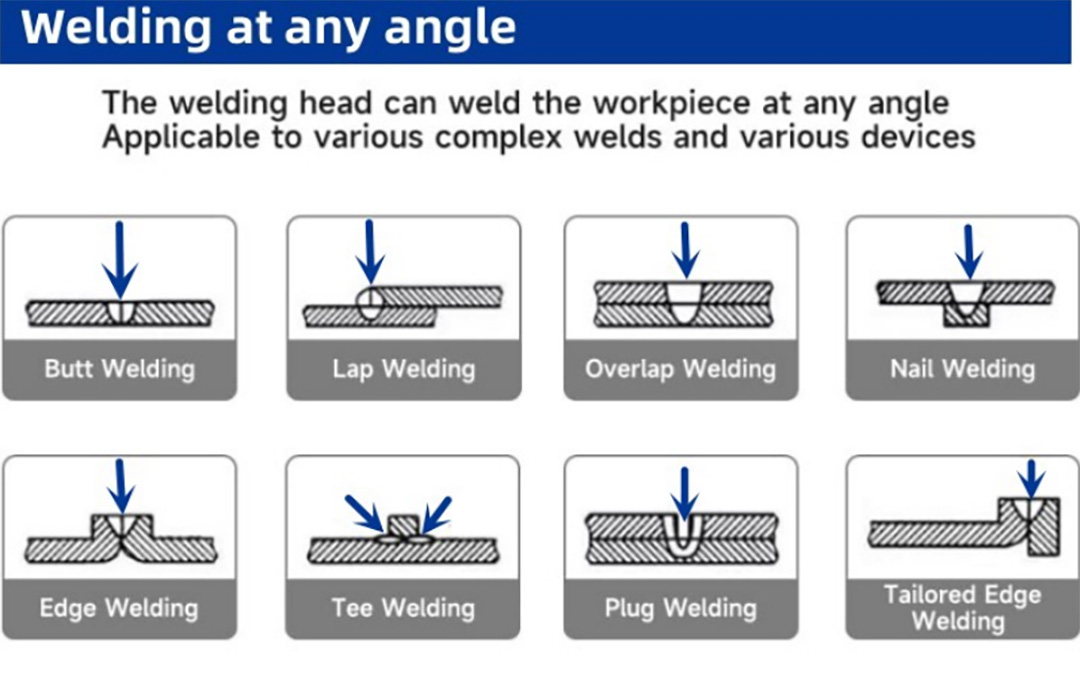

handheld tjheseletsa hlooho ke bobebe le tenyetseha, ho le bonolo ho sebetsa, ho kopana le mefuta e fapaneng ya dikhutlo, mefuta e fapaneng ya maemo a tjheseletsa, e ka phethoa holim'a workpiece ea boikaketsi likarolo tsa pono e hanyetsanang ea tjheseletsa, nahanela le loketseng, ka tjheseletsa ka ntle e felletseng, e loketseng mefuta e fapaneng ea li-welds tse bohlasoa, ho cheselletsa lisebelisoa tse fapaneng.

Hlooho e ts'oaroang ka letsoho e na le limithara tse 10 tsa fiber ea optical e tsoang kantle ho naha, e tenyetseha ebile e bonolo ho fihlella welding ea kantle. E ka finyella leha e le efe angle tjheseletsa ka workpiece, tse peli optical tsela bohlale switjha, nako-arolelanoa khanya kabo ea matla junifomo.

Mochini oa welding oa letsoho oa laser o amohela boemo ba infrared, bo sebelisetsoang ho tjheseletsa boemo ba hlooho le netefatso ea boemo ha ho tjheseletsa, boemo ba welding bo nepahetse ho feta ho netefatsa weld e ntle ho feta.

Litšenyehelo tse tlase tsa tlhokomelo: Ho chesoa ha laser handheld, ha ho tafole e ntle ea welding, thepa e tlase, tšebeliso e tlase ea matla, litšenyehelo tse tlase tsa phepelo ea lisebelisoa le litšenyehelo tsa tlhokomelo. Sebakeng se ts'oanang sa ts'ebetso, re hloka ho qeta nako e ngata ho boloka tafole ea ho tjheseletsa, ha setupo sa laser ea bukana le phepelo ea lisebelisoa e ka sebetsa ha feela e na le lisebelisoa tse ts'oarellang ka letsoho tsa laser. Ha e le phapanyetsano, theko ea lisebelisoa e tlaase.

| Mofuta | Argon arc welding | E tiileng YAG | Laser Handheld Welding | |

|

Boleng ba welding | Ho kenya mocheso | E kholo | Nyenyane | Nyenyane |

| Ho tsikitlanya ha sesebedisoa/ho phunya | E kholo | Nyenyane | Nyenyane | |

| Ho theha seam weld | mohlala oa tekanyo ea litlhapi | mohlala oa tekanyo ea litlhapi | Boreleli | |

| Kalafo ea ho latela | Ho hlokahala ho bentša | Ho hlokahala ho bentša | Ha ho letho | |

| Sebelisa Ts'ebetso | Lebelo la welding | Butle | Mahareng | Ka potlako |

| Bothata ba ho sebetsa | E kholo | Nyenyane | Nyenyane | |

| Polokeho ea Tikoloho | Kotsi ea botho | E kholo | Nyenyane | Nyenyane |

| Tšilafalo ea tikoloho | E kholo | Nyenyane | Nyenyane | |

| Litšenyehelo tsa Tšebeliso | Lintho tse ka sebelisoang | Molamu oa welding | Likristale tsa laser, mabone a xenon | Ha ho letho |

| Tšebeliso ea matla | Nyenyane | E kholo | Nyenyane | |

| Sebaka sa fatše | Nyenyane | E kholo | Nyenyane | |

Tlhaloso

| Mohlala No. | MLA-W-H1000G |

| Lebitso la Sehlahiswa | Mochini o ts'oaretsoeng ka letsoho oa fiber laser welding |

| Wavelength | 1080+/-10 nm |

| Matla a laser | 1500W,1000W |

| Tokiso ea matla | 10~100% |

| Bophara ba sebaka sa laser | QCS 3±0.5/RFL-QCS 5.5±0.5 |

| Bolelele ba fiber | Standard 15m kapa hlalosa |

| Mekhoa ea ho sebetsa | CW/ Mokgwa wa Pulse |

| Lebelo la lebelo | 0-120 limilimithara |

| Botenya ba weld | 0.5-6 limilimithara |

| Phepelo ea motlakase | 220V/50Hz/30A |

| Mekhoa ea ho phomola | Metsi a hatselitsoeng ka hare |

| Boholo ba mochini | 456*887*718 limilimithara |

| Boima bo kahare | 180 KG |

Nchafatso ea Sistimi e Ncha

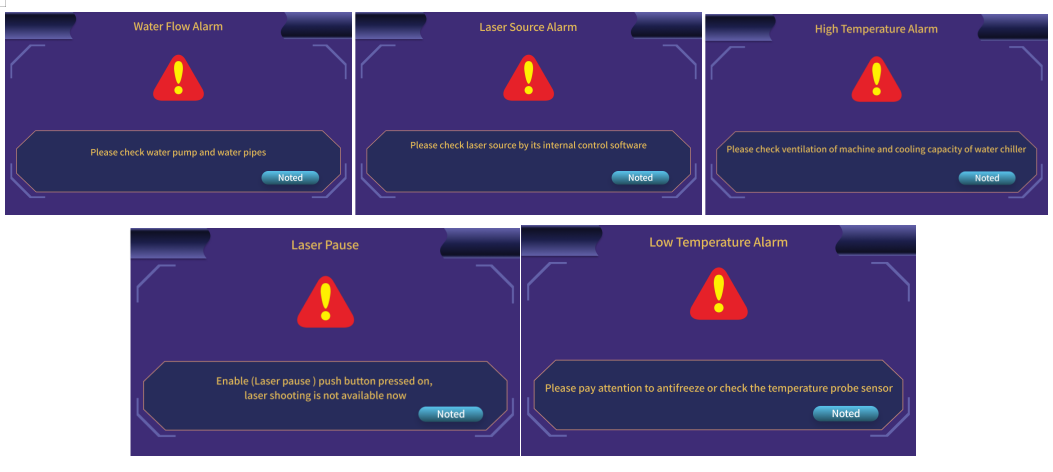

Alamo ea Phallo ea Metsi, Alamo ea Mohloli oa Laser, Alamo e Phahameng ea Mocheso, Pause ea Laser, Alamo ea Mocheso o Motla, bothata bofe kapa bofe ba laser bo tla bona tsamaisong, ho tla ba bonolo hore u fumane bothata ka kotloloho.

- boemo ba mohloli bo thusa haholo ts'ireletseho ea hau, ha u sebelisa mochine, haeba u sa pata tšireletso ea sekotwana sa fatše, tsamaiso e tla ba letšoao le khubelu ho thibela likotsi tsa ts'ireletso mosebetsing.

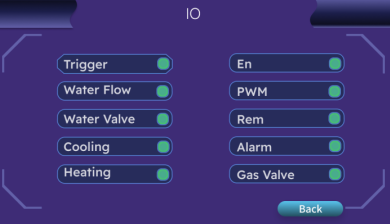

- Sistimi e ncha ea IO, tlhahlobo e felletseng ea boemo ba mochini, ha mochini oa hau e le karolo ea bothata, o tla khantša lebone le lefubelu, e le ho lemoha bothata kapele, empa hape ke ts'ireletso e matla ka mor'a thekiso.

- Lihlopha tse 8 tsa ts'ebetso ea li-parameter tsa polokelo, ts'ebetso e kholo ea memori, boloka liparamente tsa hau, haeba u hloka ho kopanya weld workpiece ea hau, ts'ebetso ena e ka u lumella ho qala mochini hape ha o kena maemong a ho sebetsa kapele.

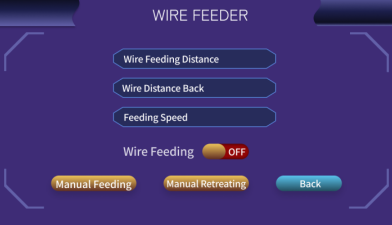

Sistimi e laola ka kotloloho sesebelisoa sa terata ka ntle ho terata, se bonolo ebile se potlakile, sesebelisoa sa terata ha se na khokahano e 'ngoe ea sistimi, senotlolo se le seng ho tsoa terata, se khona ho laola kantle le ho kena.

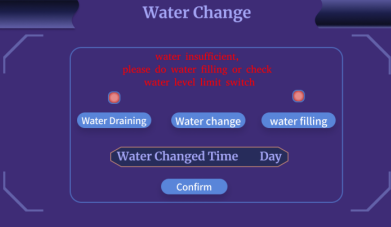

Sistimi e laola ka kotloloho metsi, sistimi ea taolo ea metsi le sistimi e kopaneng ea taolo ea khabinete, bakeng sa sistimi ea metsi ha e sa le taolo e arohaneng, malebela a nako, ha mathata a tsamaiso ea metsi a hau, u ka ba oa pele oa ho tseba.

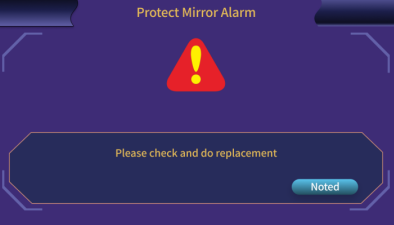

Ntlafatsa ts'ebetso ea lense ea ts'ireletso, ha u sebelisa mochini, ha lense e sireletsang e senyehile, e tla etsa hore likarolo tse ka hare tsa mochini li senyehe habonolo, alamo ea rona e ncha ea ts'ireletso ea lense e tla fokotsa haholo litšenyehelo tsa hau tsa kamora ho rekisa.

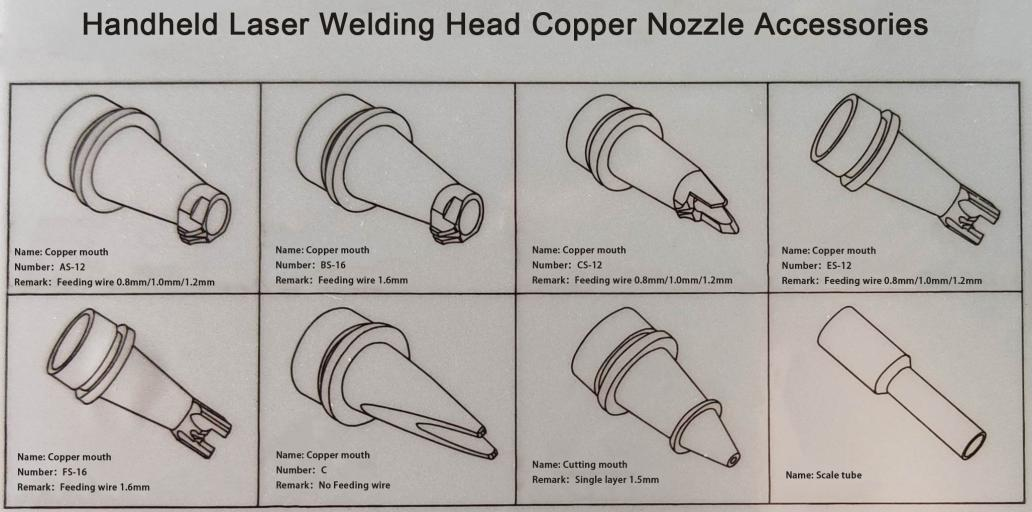

Lisebelisoa tsa mochini oa welding oa laser o tšoaroang ka letsoho

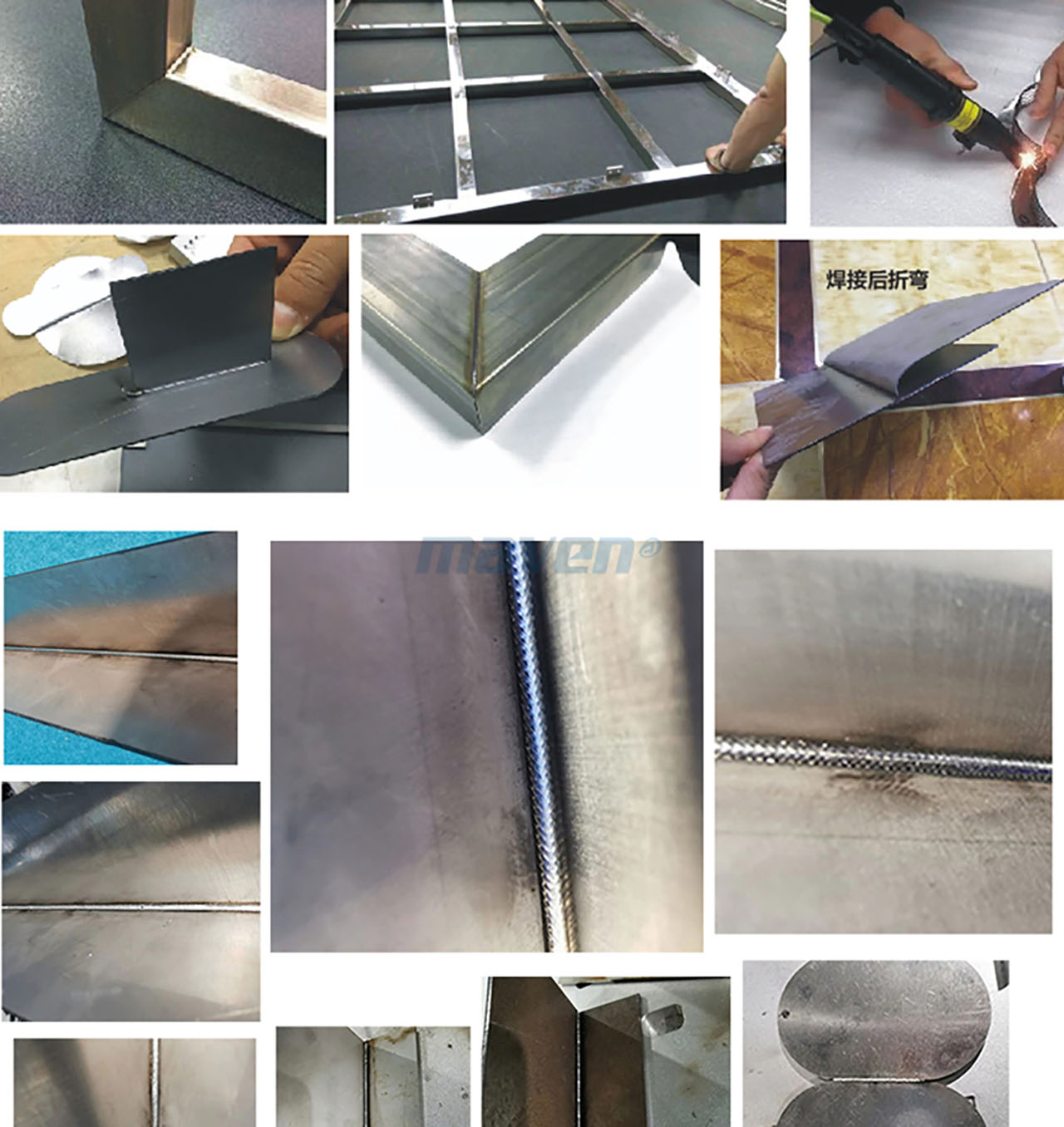

Haholo-holo bakeng sa tšepe ea tšepe e kholo le e mahareng, lik'habote, chassis, mamati a aluminium alloy le foreimi ea lifensetere, beisine ea tšepe e sa hloekang le tse ling tse kholo tse nang le boemo bo tsitsitseng joalo ka lehlakoreng le letona la ka hare, lehlakoreng le letona la ka ntle, sefofane se chesehelang seam welding, mocheso oa ho tjheseletsa sebakeng se amehileng ke e nyane, deformation e nyane, le botebo ba welding, welding solid. E sebelisoa haholo indastering ea kichine, indasteri ea lisebelisoa tsa lapeng, indasteri ea papatso, indasteri ea hlobo, indasteri ea lihlahisoa tsa tšepe e sa hloekang, indasteri ea boenjiniere ea tšepe e sa hloekang, indasteri ea mamati le lifensetere, indasteri ea mesebetsi ea matsoho, indasteri ea thepa ea lapeng, indasteri ea thepa ea ka tlung, indasteri ea likarolo tsa likoloi, jj.